Description

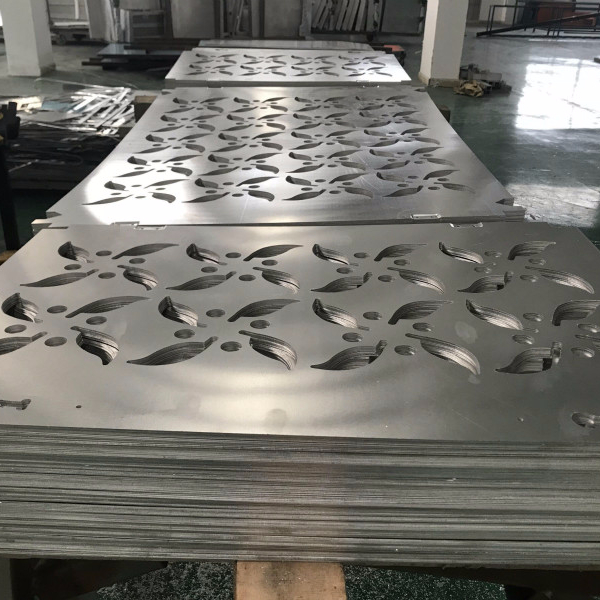

In recent years, laser cutting has gained immense popularity in the sheet metal processing industry. This cutting-edge technology has revolutionized the field of sheet metal fabrication. The key to this process lies in the laser cutting machine, which is designed to perform precise and accurate cuts through metal sheets.

One of the primary advantages of laser cutting is its non-contact nature. Unlike traditional cutting methods, laser cutting doesn’t require direct physical contact with the material being processed. This eliminates any chances of deformation or damage to the metal sheet. Moreover, the laser beam allows for intricate and complex cuts that may not be possible with conventional cutting techniques.

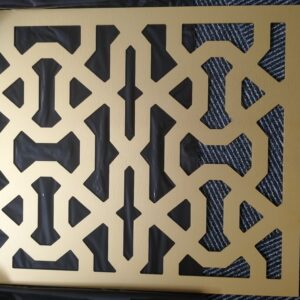

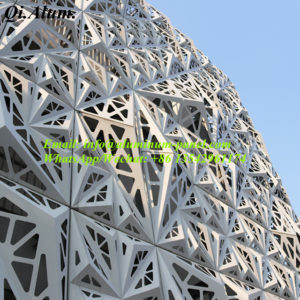

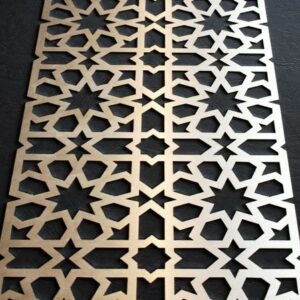

Furthermore, laser cutting offers flexibility in terms of design and customization. The laser cutting machine can be programmed to cut various shapes and patterns, enabling businesses to meet the specific requirements of their clients. This flexibility also extends to the thickness of the metal sheet. Laser cutting can efficiently handle thin sheets as well as thicker materials, making it a versatile technique for a wide range of applications.

In addition to flexibility, laser cutting ensures high precision and accuracy. The laser beam delivers a focused heat source, resulting in clean and sharp cuts with minimal material wastage. This precision allows for the creation of intricate designs without compromising the structural integrity of the metal sheet.

Speed and efficiency are also key advantages of laser cutting. The automated nature of the process enables rapid cutting and high production rates. This efficiency not only saves time but also reduces labor costs, making laser cutting a cost-effective solution for metal sheet processing.

In conclusion, laser cutting has undoubtedly transformed the sheet metal processing industry. Its non-contact nature, flexibility, precision, speed, and efficiency make it an ideal technology for businesses engaged in sheet metal fabrication. By harnessing the power of laser cutting, companies can meet the intricate demands of their customers and enhance their competitiveness in the market.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report, if there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation, but shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience,We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!