Description

Laser cutting has emerged as a significant method for cutting aluminum sheets in the metal processing industry. Over the past few years, it has gained popularity due to its non-contact nature, flexibility, precision, speed, and efficiency, making it the ideal technique in the field of sheet metal fabrication.

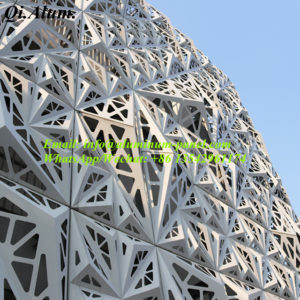

The key component enabling laser cutting is the laser processing technology incorporated in the laser cutting machine. This technology involves using a high-powered laser beam to heat, melt, and vaporize the material being cut. The focused laser beam provides a narrow cutting path with high accuracy and precision. As a result, intricate and complex designs can be achieved with minimal material wastage.

The advantages of laser cutting in metal sheet processing are numerous. Firstly, the non-contact nature of the process eliminates the need for physical contact with the metal surface, reducing the risk of damage or contamination. Additionally, the flexibility of laser cutting allows for the execution of intricate and detailed designs, enabling customization as per specific requirements.

Moreover, laser cutting offers high precision and accuracy, ensuring consistent and accurate results throughout the cutting process. This is particularly crucial in industries that demand tight tolerances and exact measurements. Furthermore, laser cutting machines can operate at high speeds, significantly improving productivity and reducing production time.

Efficiency is another key advantage of laser cutting. The automated nature of the process allows for quick setup and easy programming, minimizing human error and maximizing efficiency. Additionally, laser cutting machines can process various types of materials, including alloys and non-ferrous metals, expanding the range of applications and opportunities.

In conclusion, laser cutting has revolutionized metal sheet processing, playing a vital role in modern industrial practices. Its non-contact nature, flexibility, precision, speed, and efficiency make it the preferred technique in the sheet metal fabrication industry. By utilizing laser cutting technology, enterprises can enhance productivity, achieve intricate designs, and ensure consistent quality.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report, if there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation, but shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

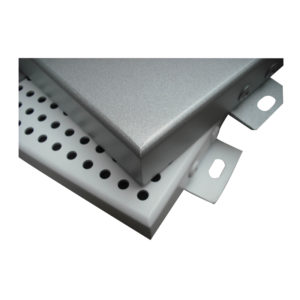

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience,We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!