Description

AA6063 Material Aluminum Polyester Powder Coating Decorative Mesh Screen

| Material | aluminum alloy; stainless steel 304, 316; brass; copper; low carbon steel, etc. |

| Wire diameter | 1-2 mm 80% customer choose 1.0mm, 13% customer choose 0.8mm, 5% customer choose 1.2mm. |

| Aperture size | 4-10mm |

| Open area | 10% – 70% |

| Surface treatment | anodic oxidation and spray painted |

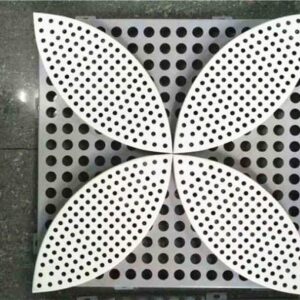

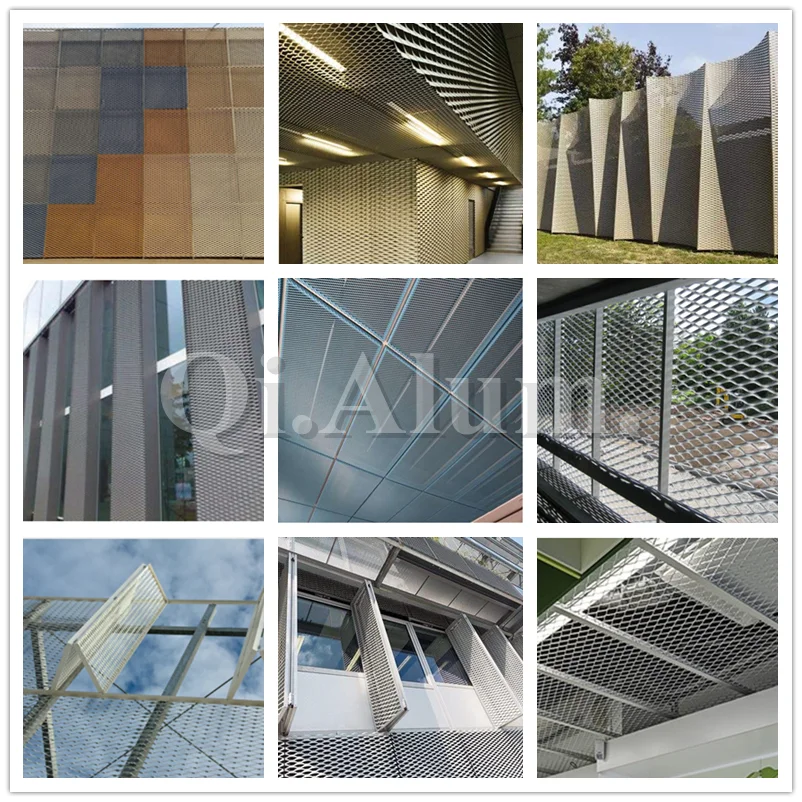

Perforated Metal Mesh

Perforated metal mesh refers to punching holes of different shapes on different materials to meet different needs.The raw materials for punching mesh are: stainless steel plate, low carbon steel plate, galvanized steel plate, PVC plate, cold rolled plate, hot rolled plate, aluminum plate, copper plate and so on.

Material: the raw materials for punching mesh are stainless steel plate, low carbon steel plate, galvanized steel plate, PVC plate, cold rolled plate, hot rolled plate, aluminum plate, copper plate and so on.

Types: pattern punching net, forming punching net, heavy punching net, extra thin punching net, micro punching net, line cutting punching net, laser punching net, etc.

Specification: The main specifications of punching net are rectangular hole, square hole, diamond hole, round hole, long round hole, hexagonal hole, cross hole, triangle hole, long waist hole, plum hole, fish-scale hole, pattern hole, eight-character net, herringbone hole, five-pointed star hole, irregular hole, drum hole, shaped hole, Louvre hole, etc.

Characteristics

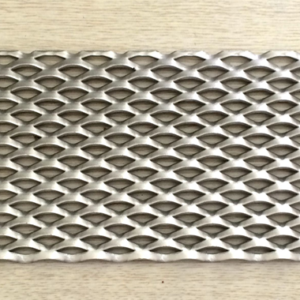

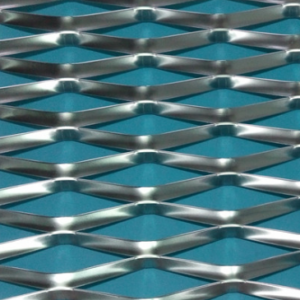

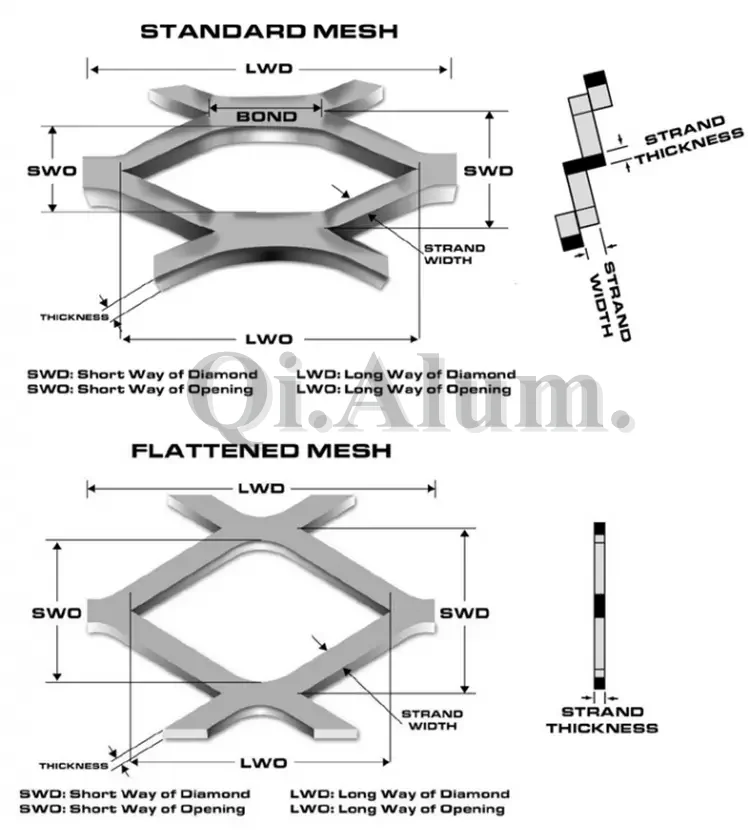

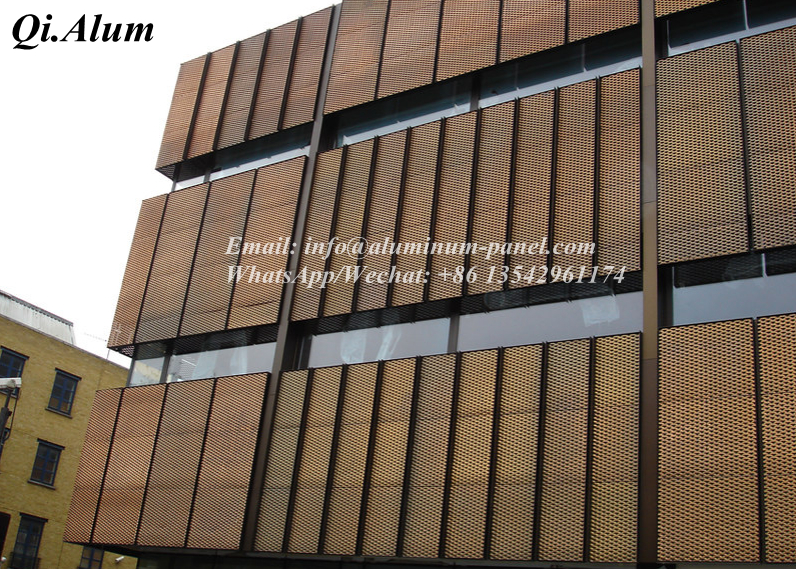

Expanded metal sheet

One of the benefits from the manufacturing of expanded metal is that the sheet retains its structural integrity because it has not undergone the stress of having shapes punched in it (like perforated sheet), and the mesh-like pattern will not unravel (like woven mesh can do). Expanded metal has been stretched rather than punched, reducing scrap metal waste; making it cost-effective. The main considerations when using expanded metal will be the chosen thickness and strand dimensions (weight and structural design requirements). Expanded metal can be almost transparent (depending on the opening); it has mechanical properties and is an excellent conductor.

Manufacturing Process

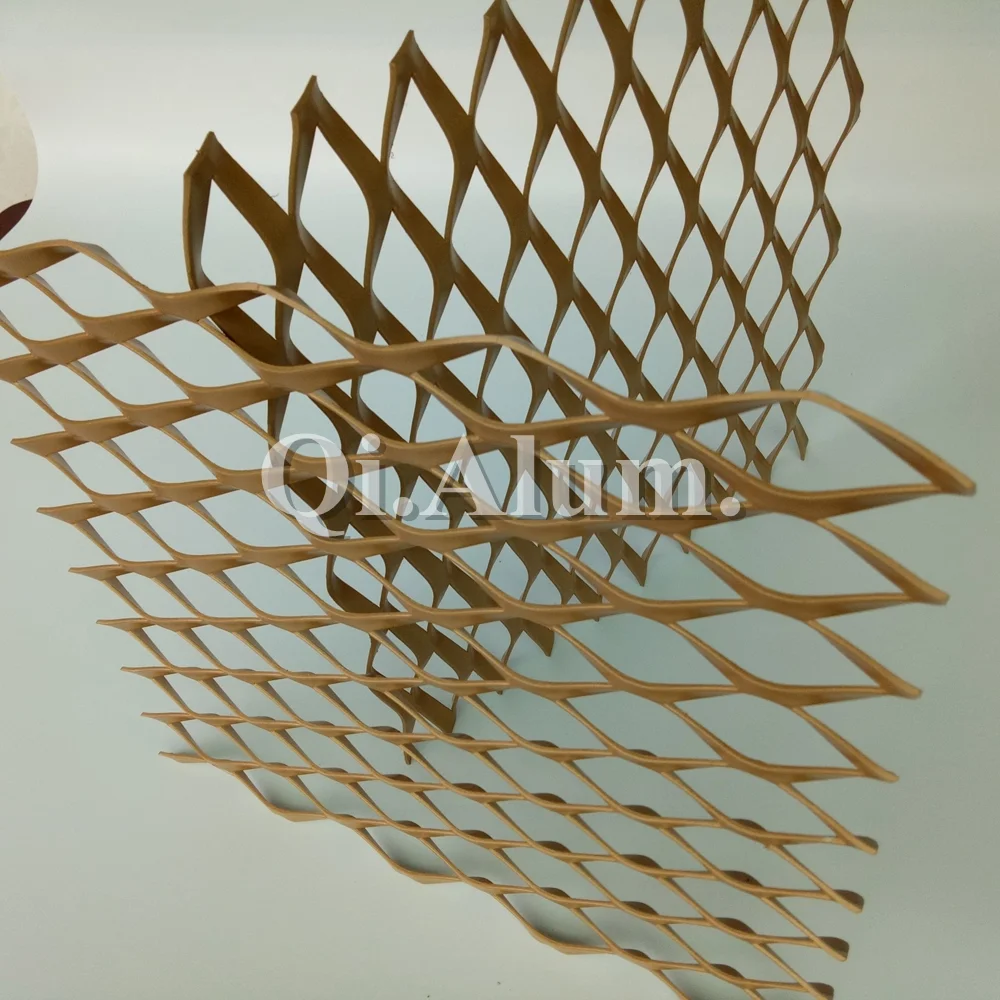

Expanded metal sheet

Expanded metal sheet is made by first creating multiple slits in the sheet, and then stretching the sheet. The stretching creates a unique diamond pattern opening with one of the strands protruding at a slight angle. These raised strands can be flattened later in the process if desired. As you can see this process creates no waste (thus keeping down production costs) and it can add structural strength to the product.

|

Product name

|

Aluminum expanded/deployed mesh

|

|||

|

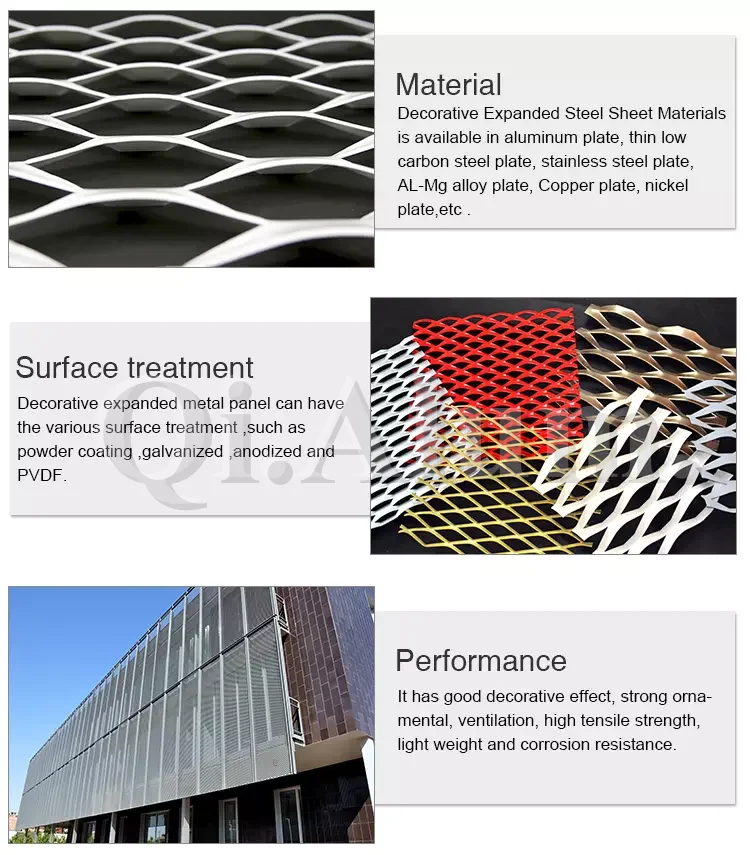

Material

|

Aluminum Alloy AA1100, 3003, 3014, 5005, 5015, 6063 etc.

|

|||

|

Size

|

within 1400*4000MM,customized

|

|||

|

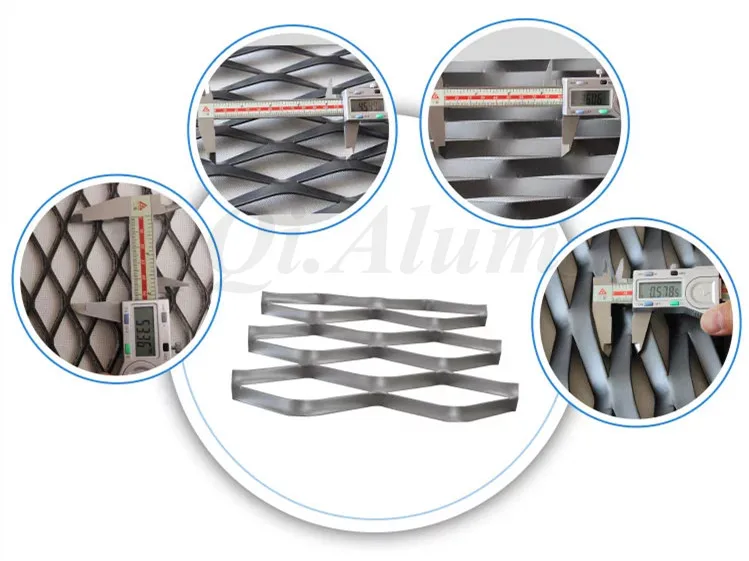

LWD*SWD

|

Customized

|

|||

|

Strand

|

1mm,1.5mm,2mm2.5mm,3mm,3.5mm,4mm,4.5mm,5mm,5.5mm,6mm etc.

|

|||

|

Thickness

|

1mm,2mm,3mm,4mm,etc

|

|||

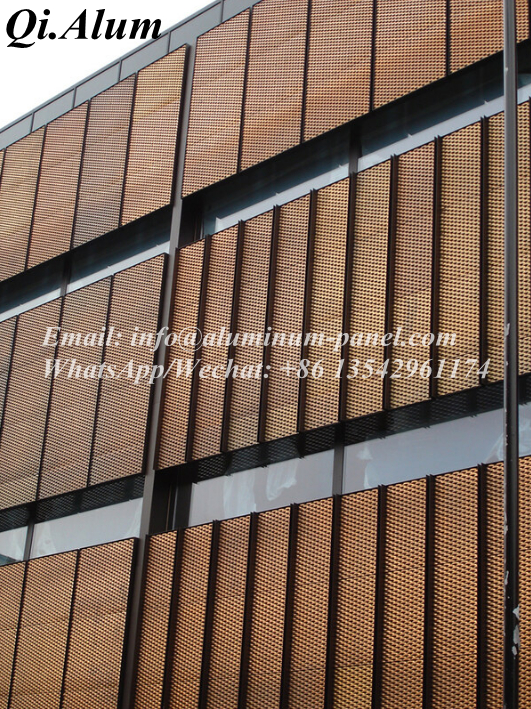

|

surface treatment

|

mill finish,Anodized, powder coated or PVDF spraying,PPG

|

|||

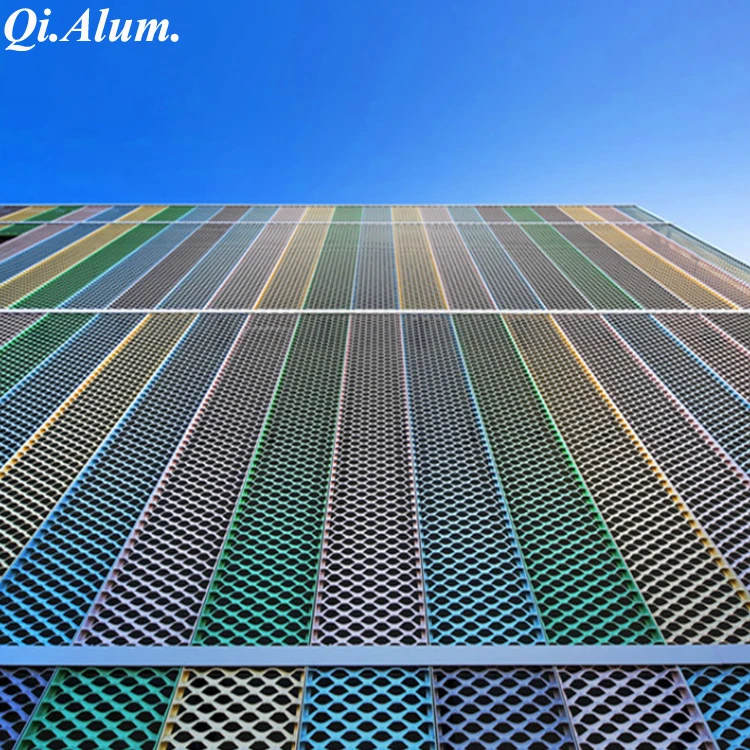

|

Color

|

any color of RAL and Pantone color chart,customized

|

|||

|

Opening

|

5%~50%

|

|||

|

Main Production Process

|

Cutting,CNC Punching,Laser Cutting,Bending, Welding,Painting.

|

|||

Factory equipment:

Certifications

Packaging Details:

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!