Description

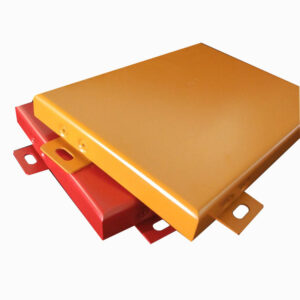

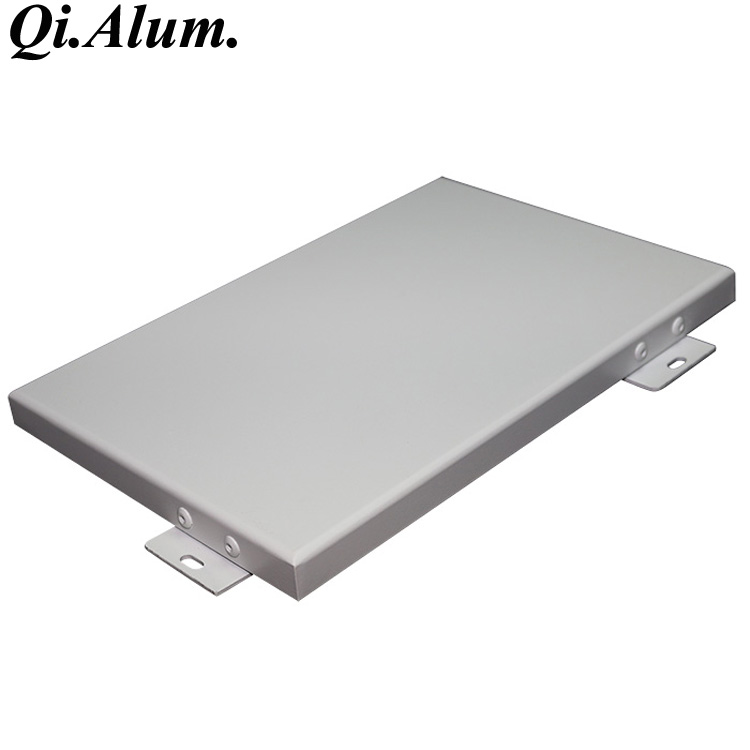

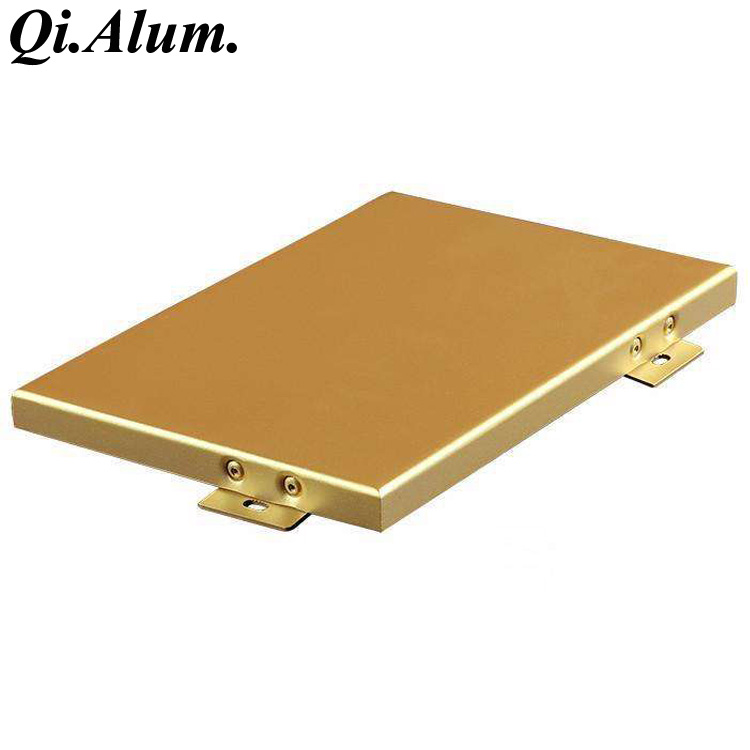

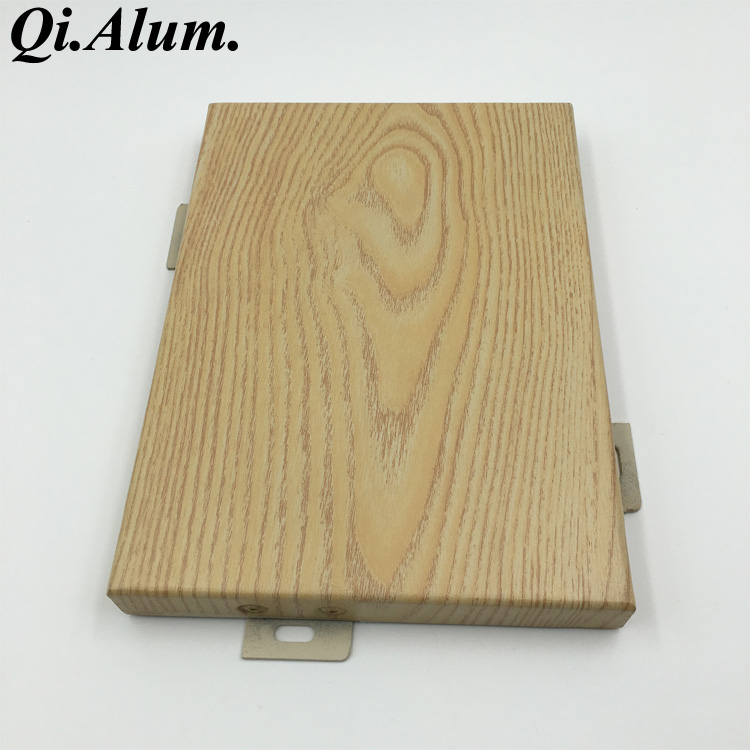

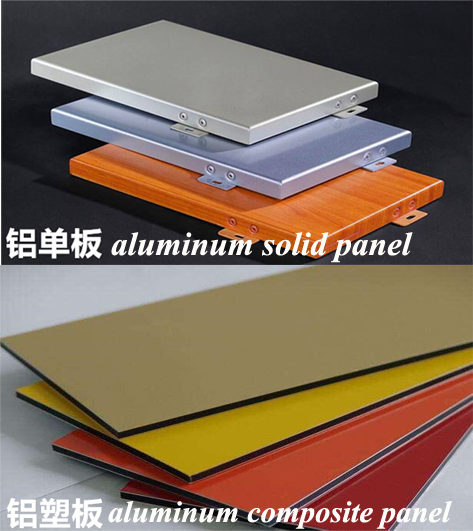

Aluminum solid panel is a building decoration material processed by fluorocarbon spraying technology after chrome treatment. Fluorocarbon coating mainly refers to poly vinylidene fluoride resin (KANAR500), divided into primer, finish, varnish three. Spraying process is generally divided into two coating, three coating or four coating. Fluorocarbon coating has excellent corrosion resistance and weather resistance, acid rain resistance, salt fog and a variety of air pollutants, excellent cold and heat resistance, can resist strong ultraviolet radiation, can maintain long-term colorless, not powdering, long service life.

1、 light weight, good rigidity, high strength 3.0mm thick aluminum panel weight 8kg per square panel, tensile strength 100-280N /mm2

2、 Good durability and corrosion resistance. PVDF fluorocarbon paint with kynar-500 and hylur500 as base material can be colorfast for 25 years.

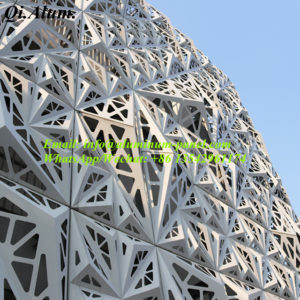

3、 good technology. The aluminum panel can be machined into various complex geometric shapes such as plane, arc and sphere.

4、 Uniform coating and diverse colors. Advanced electrostatic spraying technology makes the adhesion between paint and aluminum panel uniform, diverse colors, large choice space.

5, not easy to stain, easy to clean and maintain. Fluorine coating film non-adhesion, so that the surface is difficult to adhere to pollutants, more good cleaning.

6、 Convenient installation and construction. Aluminum panel in the factory molding, construction site does not need to cut, fixed on the skeleton.

7、can be recycled, beneficial to environmental protection. Aluminum panel can be 100% recycled, different from glass, stone, ceramic, aluminum panel and other decorative materials, recycling residual value is high.

The construction process of Aluminum Composite Panels and aluminum solid panel is roughly the same. The largest aluminum panel is processed into the required shape and specifications at the site, with greater freedom of construction. The aluminum solid panel is processed and formed by manufacturers. Due to the relationship between the precision of domestic equipment, it often encounters some little trouble in the process of construction. In addition, the construction process of delivery guarantee, the mass production of Aluminum Composite Panels is much faster than the production of aluminum solid panel, and the schedule assurance system is also higher.

Aluminum Composite Panels is made of chemically treated coated aluminum panel as the surface material, polyethylene plastic as the core material, and processed in special Aluminum Composite Panels production equipment. The unique performance of Aluminum Composite Panelsitself determines its wide use: it can be used for building external walls, curtain wall panels, renovation of the old building, indoor wall and ceiling decoration, advertising signs, display stands, purification and dustproof engineering. It belongs to a new building decoration material.

Aluminum Composite Panels (also known as aluminum-plastic panel), as a new decorative material, has been introduced from Germany since the end of 1980s and the beginning of 1990s

To China, it is rapidly favored by people for its economy, the diversity of optional colors, convenient construction methods, excellent processing performance, excellent fire resistance and noble quality.

In foreign countries, there are many kinds of Aluminum panel name, called Aluminum Composite Panels; There’s something called Aluminum Composite Materials

[Aluminum Composite Panels] is composed of two different materials (metal and non-metal). It not only retains the main characteristics of the original material (metal aluminum, non-metal polyethylene plastic), but also overcomes the shortcomings of the original material, thus obtaining many excellent material properties. Such as luxury, colorful decorative, weather resistance, corrosion resistance, impact resistance, fire, moisture, sound insulation, heat insulation, earthquake resistance; Light weight, easy processing molding, easy handling installation and other characteristics. Therefore, it is widely used in all kinds of architectural decoration, such as ceiling, column, counter, furniture, telephone booth, elevator, storefront, billboard, factory wall materials, etc., has become the representative of the three curtain walls (natural stone, glass curtain wall, metal curtain wall) metal curtain wall, in developed countries, Aluminum Composite Panels is also used in the manufacture of buses, railway carriages, sound insulation materials of aircraft and ships, and the design of instrument boxes.

Aluminum Composite Panels is easy to process, forming a good material. It is an excellent product for the pursuit of efficiency and time, which can shorten the construction period and reduce the cost. Aluminum Composite Panels can be cut, cut, slotted, band saw, drilling, processing countersunk, but also can be cold bending, cold folding, cold rolling, riveting, screw connection or gluing bonding.

1, good weather resistance, high strength, easy maintenance.

2. Convenient construction and short construction period.

3, excellent processing, heat break, sound insulation and excellent fire performance.

4, good plasticity, impact resistance, can reduce the building load, good shockproof.

5, smooth good, light and firm.

6. Many colors to choose from.

7, the processing machine is simple and can be processed on site.

8. Patterns and patterns can be customized

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!