Description

With the development of science and technology, conventional materials (metal, concrete, ceramics, etc.) are far from meeting the requirements of human beings in certain structural design aspects, especially in energy absorption and buffer design. People have gradually turned their attention to porous structural materials, and the emergence of aluminum foam has opened a new way for people.

As a new functional material, aluminum foam material has the characteristics of low relative density, light weight, large specific surface area, high mechanical performance, good damping performance, noise elimination, heat insulation, heat conduction, shock absorption, electromagnetic shielding protection, energy absorption and buffering, and has the advantages of multi-functional compatibility, green color, environmental protection, user friendliness, etc. It will play an important role in automobile, ship, aviation, aerospace, weapons, electronics, environmental protection, transportation, building materials, etc, It can be used as high temperature resistant curtain wall materials, sound insulation materials and decorative materials. However, because its technology does not reach structural controllability and its production cost is high, it has not been used more widely. With the solution of these problems and China’s gradual attention to environmental protection and user health, the laws on building environmental protection performance are gradually improved, and foam aluminum materials will be used more and more widely as building materials.

As we all know, the new aluminum foam plate has good sound absorption performance, stable acoustic performance, pollution-free, light weight, beautiful, fireproof, waterproof, good physical performance, and easy processing. It is used to make various forms of sound absorbers, silencers, sound insulation structures, sound barriers, noise reduction rooms, sound insulation covers, etc., which can directly face the noise source without any protective panels and other sound absorption fillers. Good acoustic performance: average sound absorption coefficient ≥ 0.60 (125-4000Hz frequency range, measured by the Institute of Acoustics of Tongji University); At the same time, it has excellent acoustic performance without changing the sound absorption performance after water spraying and ash spraying on the board. Aluminum foam plate is formed by aluminum alloy die-casting. After being damaged, it can be completely recycled. It is a new green environmental protection high-tech product that does not cause secondary pollution to the environment at present.

Aluminum foam plate is the leading edge and replacement product of non fibrous materials in the world at present. It will not cause secondary pollution to the atmospheric environment like glass fiber, mineral wool, rock wool, etc. after aging in the sun, rain, high temperature and other environments. It has the corresponding fireproof incombustibility, weather resistance, corrosion resistance, aging resistance of metal aluminum, and can withstand wind, rain and sun. It is a Class A incombustible product. The coating can be applied with different colors, which is beautiful. The coating undergoes multiple thin spraying, drying, and other processes, so it will not fade even under wind and sun conditions. It has good electromagnetic shielding performance. The aluminum foam sound-absorbing board can be sawed, bonded, riveted and inserted at will, and is easy to install. Aluminum foam plate can be made into various forms of sound absorbers, and can also be combined into various forms of sound absorption and insulation. The surface is easy to clean and easy to maintain, making it a good choice in architectur

FAQ

Q: Are you a factory or a trade company?

About us

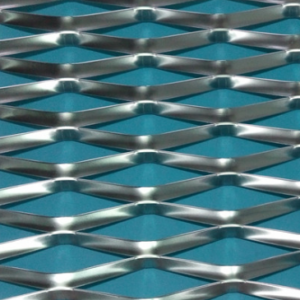

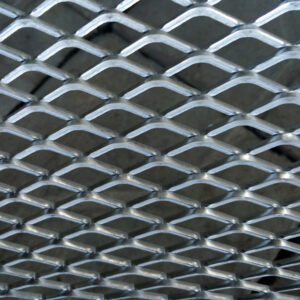

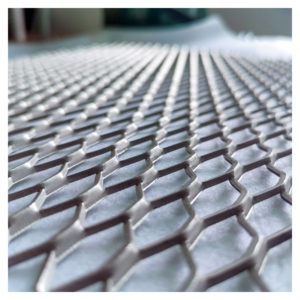

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!