Description

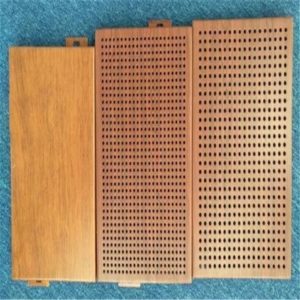

Aluminum composite plate, also known as aluminum composite material, is a composite material made of two layers of aluminum plate covered with decorative and protective coatings and intermediate mineral filled core material through hot extrusion processing on specialized production equipment.

The first aluminum composite plate in the world is called ALUCOBOND , Developed and invented jointly by Swiss Aluminum and BASF, it has been introduced from Germany to China since the early 1990s and is widely used in areas such as building exterior walls, curtain wall panels, renovation of old buildings, interior walls, and ceiling decoration.

The aluminum composite plate is composed of an aluminum alloy panel and an intermediate core material through a polymer adhesive film. The surface layer is made of 3000 series aluminum manganese alloy or 5000 series aluminum magnesium alloy with a thickness of 0.5 mm. The surface of the aluminum alloy is coated with decorative and protective fluorocarbon resin coatings. Currently, the fluorocarbon pre roller coating baking process is commonly used.

As a new type of architectural decoration material, aluminum composite panels have quickly gained the favor of architects due to their unparalleled flatness, variable surface treatment capabilities, excellent processing performance, convenient construction methods, and excellent fire resistance.

The adoption of a new process for aluminum clad panels has improved the most critical technical indicator, “peel strength,” to an excellent state, resulting in a corresponding improvement in the flatness and weather resistance of aluminum clad panels.

Aluminum composite panels typically use an open curtain wall installation system, which is simple and fast to install, reducing construction costs.

Compared to traditional glued closed curtain walls, open curtain walls are more in line with building energy conservation requirements and extend building life. With the most economical curtain wall structure, the overall construction cost of building exterior walls is reduced.

FAQ

Q: Are you a factory or a trade company?

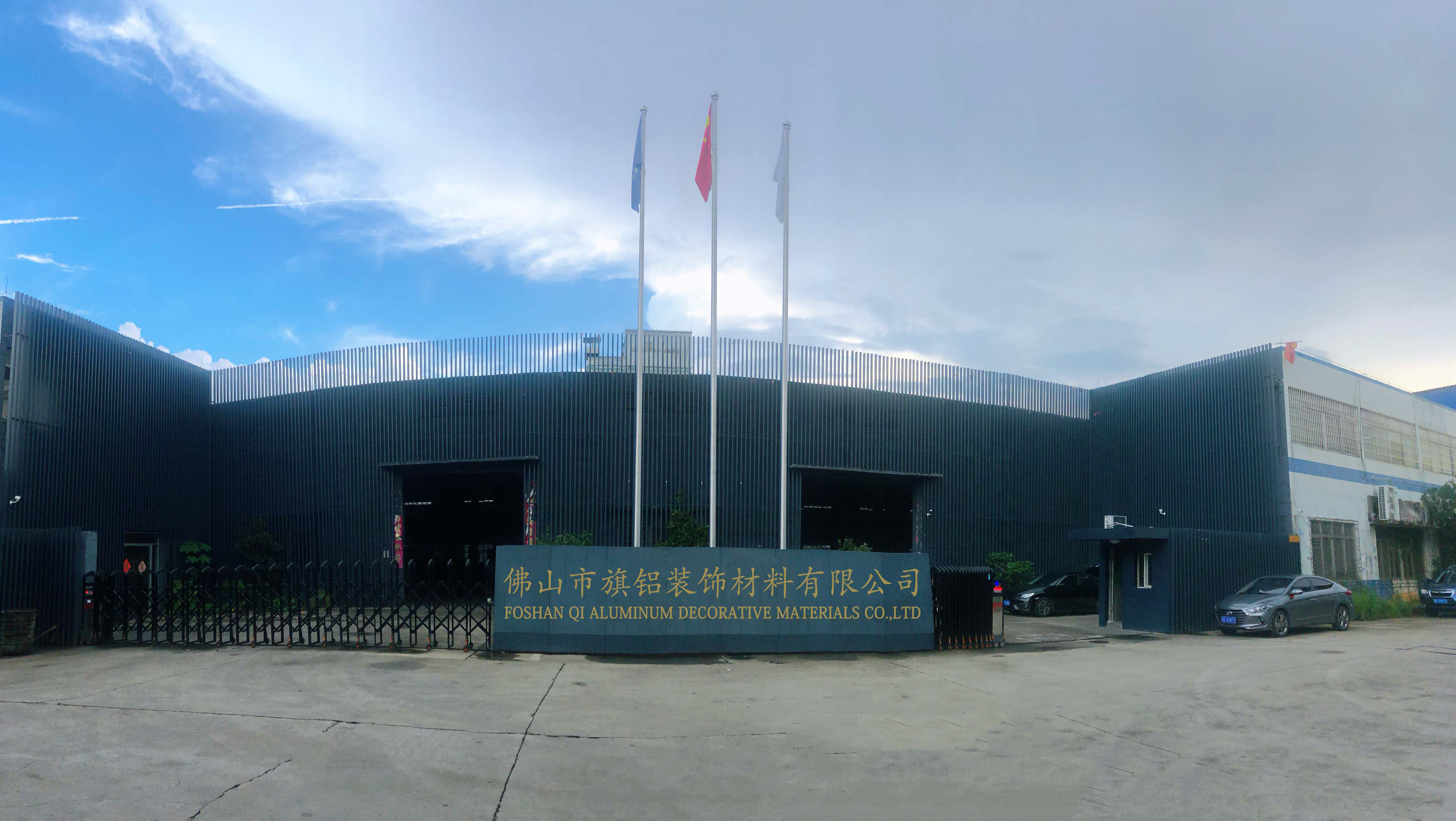

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!