Description

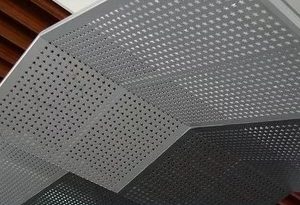

Outdoor Architecture Aluminum Perforated Facade Panels

Product Description

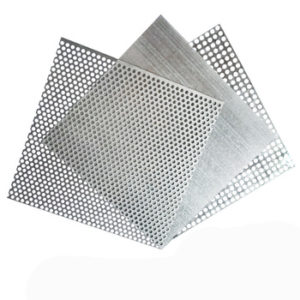

| Product Name | Outdoor Architecture Aluminum Perforated Facade Panels |

| Material | Aluminum Alloy AA3003H24 |

| Thickness | 0.8mm, 1.0mm, 1.5MM, 2.0mm, 2.5mm, 3.0mm |

| Width | 300/450/600/900/1100/1200/1220/2400/2440mm |

| Length | <6000mm |

| Surface Finishing | Powder coating,PE coating,PVDF coating,Anodizing,Shot-blasting |

| Color | RAL color,Wood Imitate,Stone Imitate,Mirror,brushed brass |

| Other Remarks | Can be customize |

Application:

1. Exterior curtain wall, wall cladding and facade

2. Old building decoration and renovation

3. Subway station, hotel, university

4. Shopping mall, supermarket decoration

5. Subway station, hotel, university…Interior wall, ceiling, balcony and screen

Our Advantages:

1. We have a group of professional engineers, most of whom has more than 10 years’ experiences in architecture field.

2. Established for more than ten years, our company has got a various of experiences in design, manufacture, installation and so on. The work staffs have excellent skills. Some of them had helped customers to install the warehouse around the world.

3. We also have possessed more than 80 sets of large precise and domestically advanced processing equipments, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, slitters, shot blasting machines and so on.

4. Besides manufacture according to customers’ requirements, we also established a set of production standards. With perfect technique, excellent quality, reasonable price, top-grade services, we have won the favor of lots of customers at home and abroad.