Description

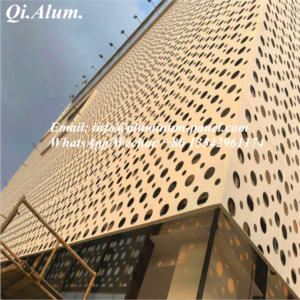

Canada project Aluminum perforated panel micro hole PVDF power coating

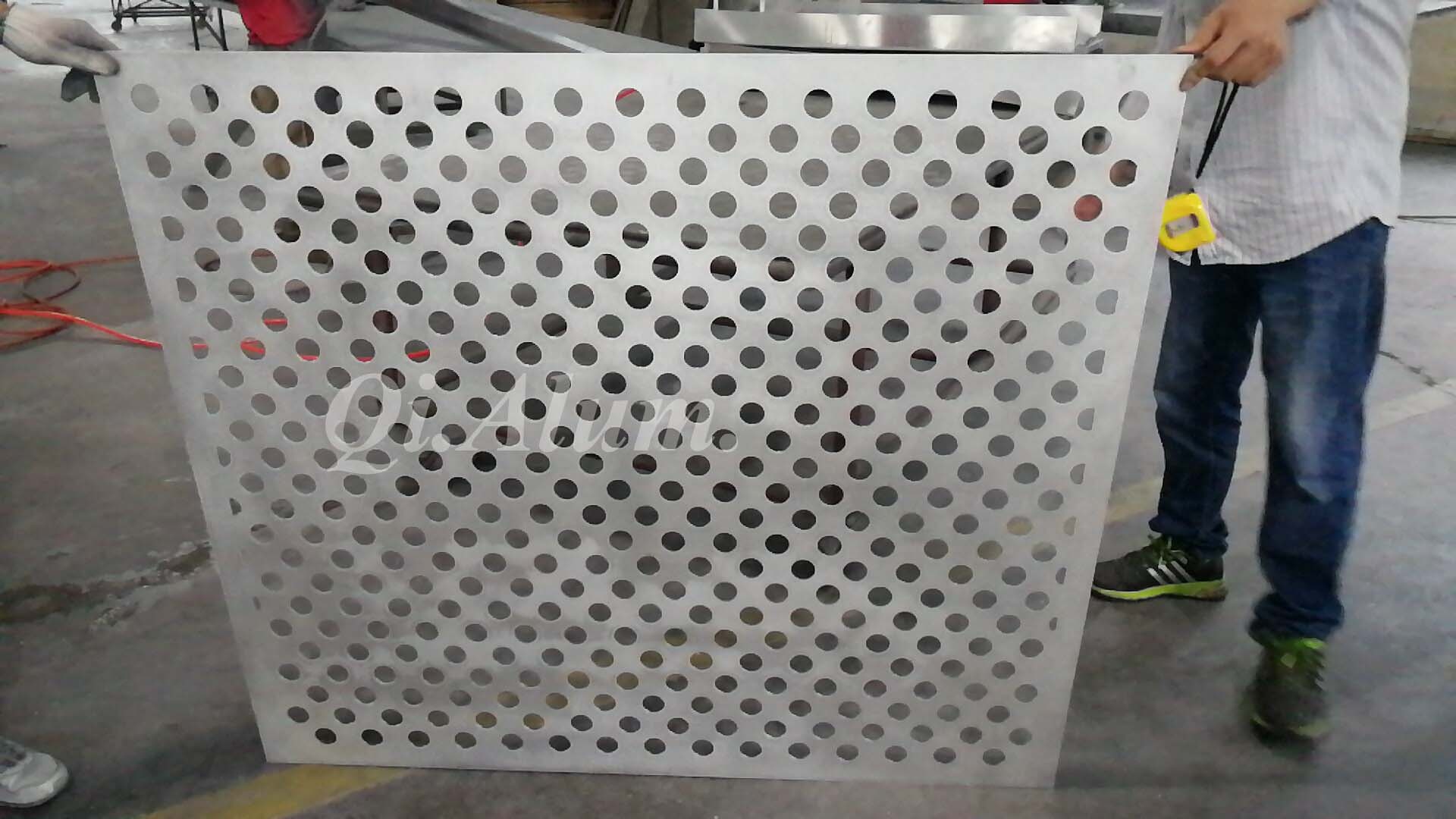

Production of sheet metal:

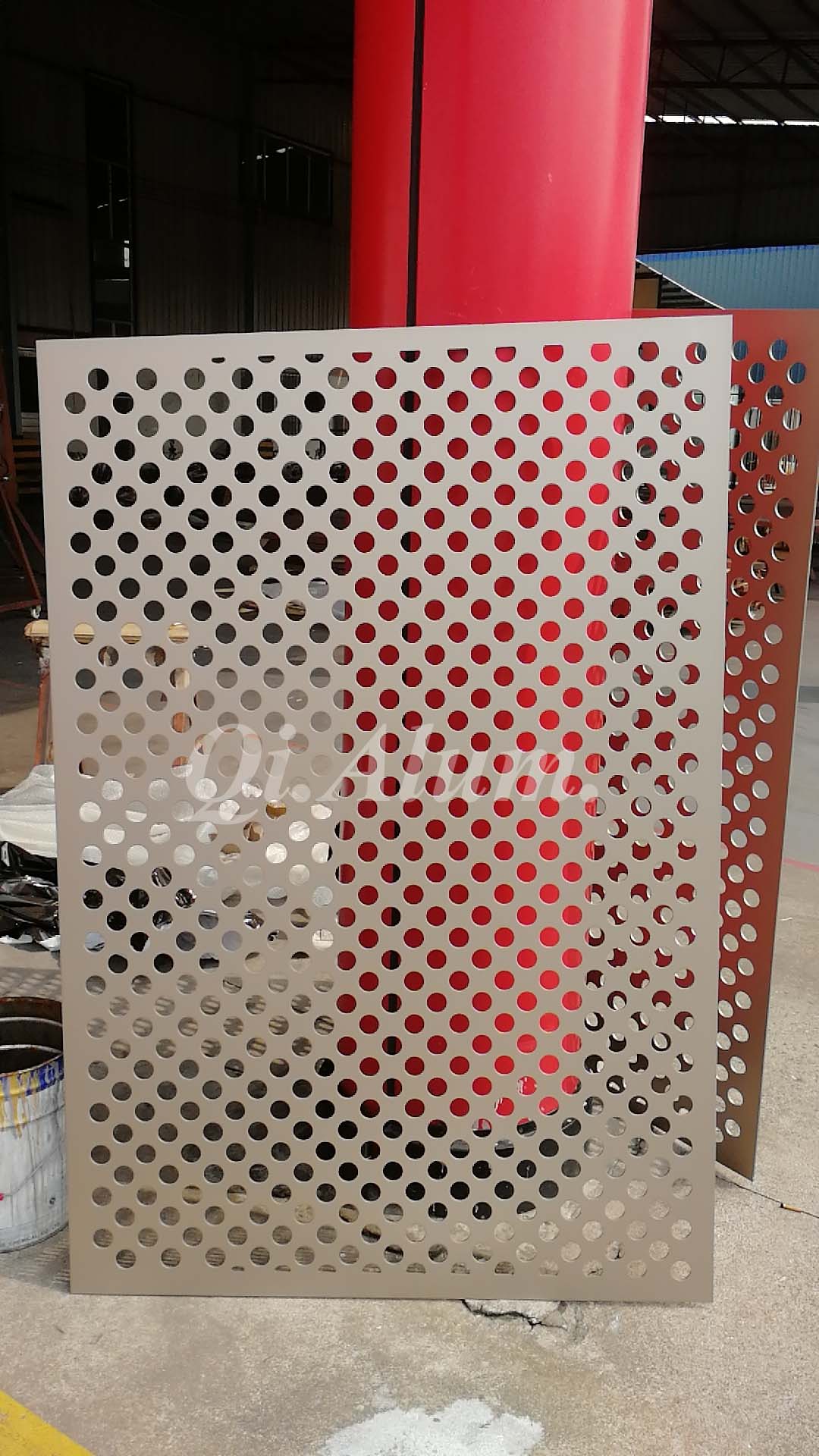

Sheet metal spraying:

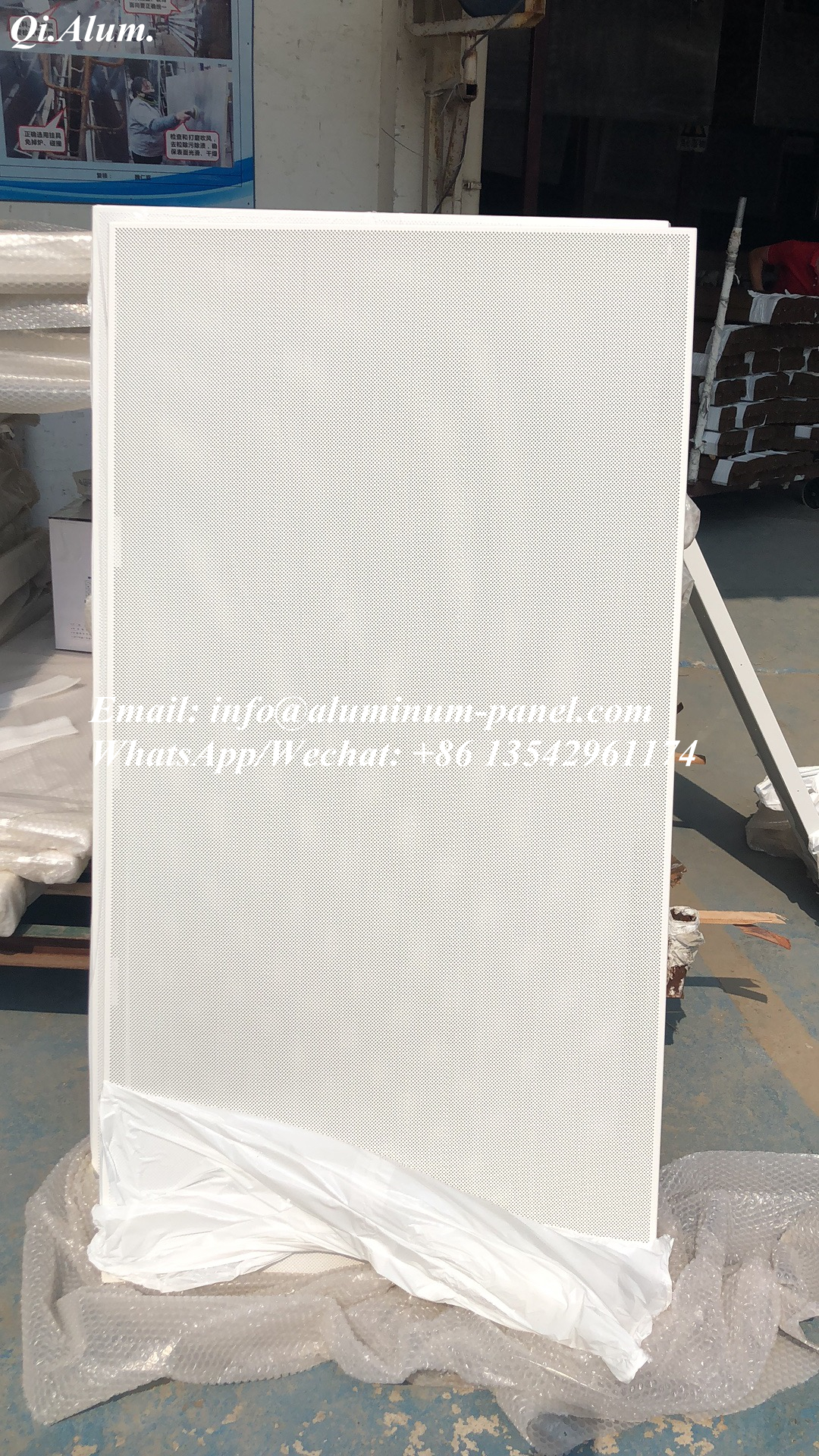

Product packaging:

Packing Details:

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request.

3. Excellent in weather fastness and corrosion resistance.

4. Good fireproof and waterproof property.

5. Even coating, various colors.

6.Easy to process ,easy to maintain.

The container shipping:

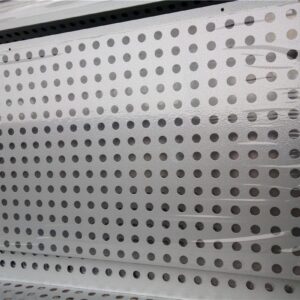

Punching Sheet Hole:

Rectangular hole , Square hole , Diamond hole , Hole , Hexagonal hole , Cross hole , Triangle hole , Long hole , Along waist hole , Plum blossom hole , Scale hole , Hole Pattern , Star shaped holes , Irregular holes ,Drum hole etc,

Surface Treatment Process:

Skim →Alkali-Corrosion → Blare-elimination(by acid) →Chromiumizing → Drying → Parts-installation →Spraying Solidifying → Parts- removing → QC& Packing

Fabrication Process:

Sheet Metal Cutting- CNC Cutting(Punching,Laser Cutting-Hollow out)- Bending- Welding-Bracket Fixing-Polishing-Surface Treatment- QC-Package

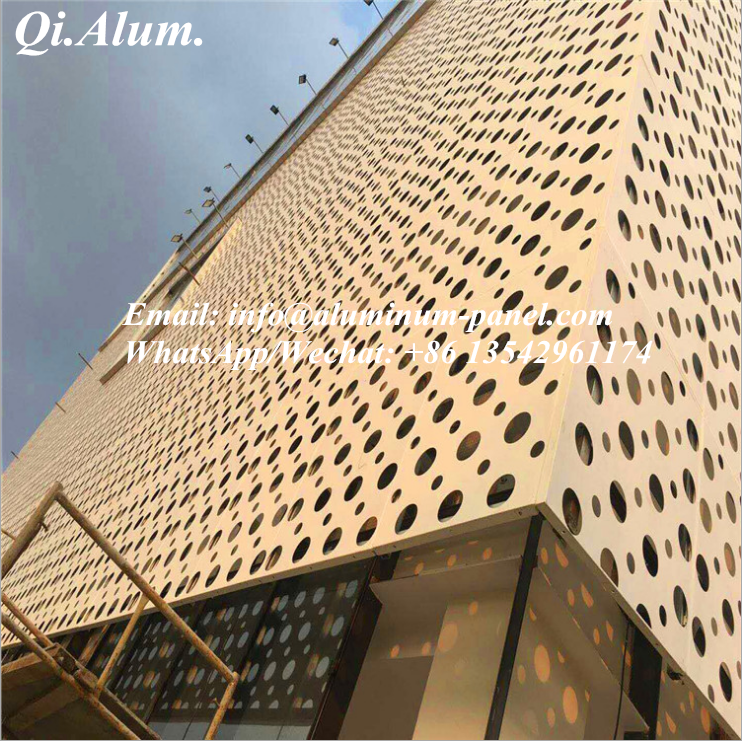

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence :

Decorative Living Room, Hotel, Bar, etc.

Indoor and outdoor public space backdrop, Elevator cabin, handrail,living room, background wall, ceiling, Kitchen equipment.

Specially for bar,club,KTV,hotel,bath center,villa,shopping mall

Canada project Aluminum perforated panel micro hole PVDF power coating:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

Projects list:

Q1: What is delivery time? A: 4 weeks days after deposit. Except for public holidays.

Q2: How can you guarantee the quality? A: We have rigorous quality test system, from raw materials to finished products, the materials must be checked and signed by QC people.

-300x300.jpg)