Description

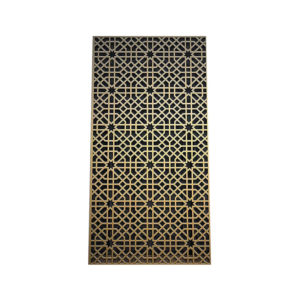

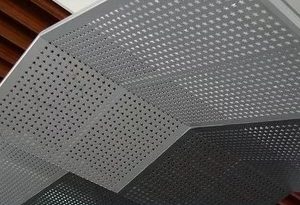

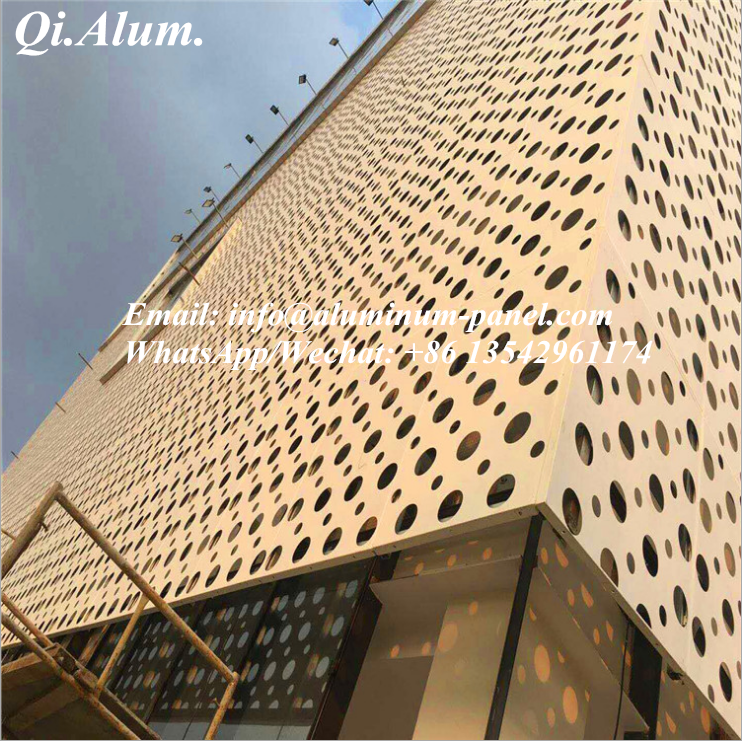

A1050 Engraved Perforated Sheets For Building Ceiling Decoration

Details

|

Aluminum ceiling |

Product | Aluminum Ceiling Tile |

| Size | 300*300mm or customized | |

| Thickness | 0.4mm, 0.5mm, 0.6mm | |

| Materials | Aluminum, Aluminum alloy | |

| Pattern | Plain , embossed | |

| Weight | <1.65KG/m2 | |

| Packing | 762*320*320mm 60pcs/CTN | |

| Application | Kitchen, bathroom,living room,etc. |

| Aluminum Composite Panel Series | |

| PVDF Series | The surface of PVDF aluminum composite panel is Polyvinylidene Fluoride (pvdf, 70%contents) with good weather resistance, impact resistance, UV resistance, sound and heat resistance, colorful, smooth and beautiful. Its life is about 20 years. It is mainly used for exterior decoration. |

| PE Series | PE is a kind of new green composite material which compounded of two layers of aluminum sheets and nontoxic low-density polyethyene (LDPE) by macromolecule adhesive film of American DuPont Company through thermo compression, The coating of the aluminum sheet is polyester coating with UV resistance, Its life is about 15 years. It is mainly used for interior decoration and advertisement board. |

| Mirror Finish Series | The surface of the mirror finish ACP is the aluminum sheet that looks like a mirror. The back surface is aluminum sheet with anti-corrosion. The mirror finish ACP has the features of mirror effect, light weight, difficult to break, high strength, can be bent and easy to process. Thanks to those features, mirror finish ACP is increasingly used for interior decoration, especially in ceiling, Cabinet panel, household appliance, furniture. |

| Fire-resistant Series | Fire-resistance ACP is a kind of green fire-resistant composite material which is compounded of two layers of aluminum sheet and special low-density polythylene (LDPE) with fire-resistance. The coating of its surface is PE or PVDF coating. The core material is compounded by fire-resistant MGOH, NAOH and PE Polyster, so it has the feature of good fire-resistance which can reach B1 class. |

| Drawing Finish Series | Drawing finish ACP is compounded of drawing aluminum sheet, the anti-corrosion aluminum sheet, and nontoxic low-density polyethylene . Thanks to the drawing treatment, its appearance is very beautiful. It is widely used for interior decoration, especially in ceiling, Cabinet panel, household appliance, furniture. |

Protective film

A layer of PE plastic tape, to protect the panel surface from scratch or damage. The thickness and sticky standard are various upon different supplier.

Color coating

By function: PE & PVDF. PE is used for interior, with 10 year life-long expectancy; PVDF coating, with resistance on UV, acid and alkali, is more suitable for exterior usage, with 15-20 year guarantee.

By color/pattern: solid color, metallic color, brushed finish, mirror finish, marble pattern, wooden pattern.

Aluminum skin

AA1100 and AA3003 are standard, other series are optional upon specified order.

Polyethylene core

By color: White PE core and Black PE core;

By function: Normal PE core, unbreakable PE core and fire-rated PE core.

Bottom coating

Mill finish or color service coating

Packing

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request.

Application:

1.Interior or exterior wall panel for all public buildings such as airport,railway station,hospital,shopping mall,etc.

2.All kinds of column cover and corner cladding.

3.Indoor ceiling for decoration.

4.Different instrument shell such as air condition cover,elevator cover.

5.Outdoor billboard ,signage.

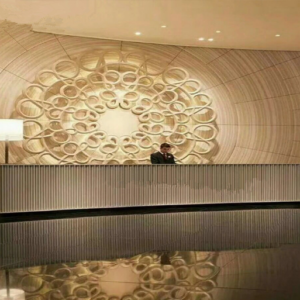

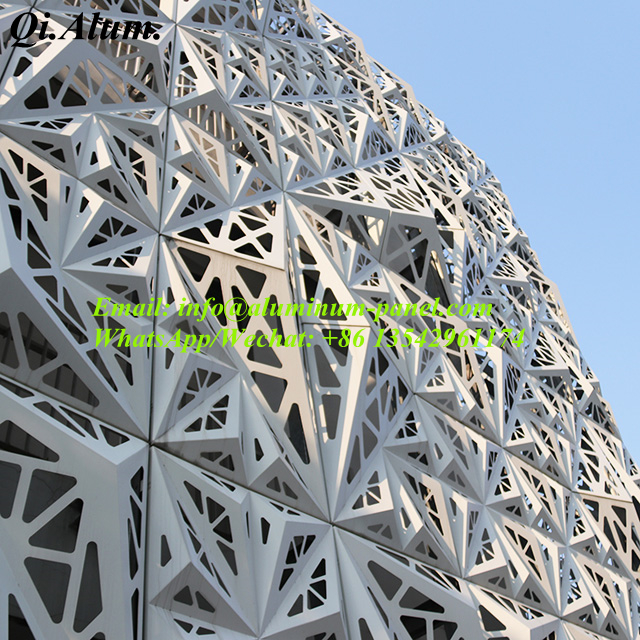

Carved aluminum panel characteristics

1, the appearance of the atmosphere, exquisite workmanship.

2, light weight, good rigidity, high strength; Good weather resistance and welding performance;

3, easy to clean, maintenance, excellent anti-pollution performance;

4, a wide range of color selection decoration effect is good. Compared with the traditional aluminum-plastic board, it has the characteristics of easy on-site processing and small loss, especially the steel and strength of the aluminum-plastic board curtain wall.

5, carved aluminum panel using fluorocarbon spraying, not ultraviolet, humidity, temperature and atmospheric corrosion, never fade; Plate body lightweight, simple installation structure, but also has good bending strength and excellent wind resistance.

The scope of application of carved aluminum panel:

Carved aluminum panel is widely used: Aluminum panel of carve patterns or designs on woodwork is consumer market demand of a new type of curtain wall decoration materials, application is very wide, can be used in curtain wall, door head, present building, billboard, partition, screen and other places of use, design can be customized, can choose the patterns of the national wind, also can choose the most modern European style design, can meet the demand of all kinds of decoration. Rich color, can be customized color matching, to create a perfect personality of carved aluminum panel. Carved aluminum panel is personalized, unique and exquisite, easy to install and easy to maintain. The installed space is pleasing to the eye, with a harmonious and artistic atmosphere.

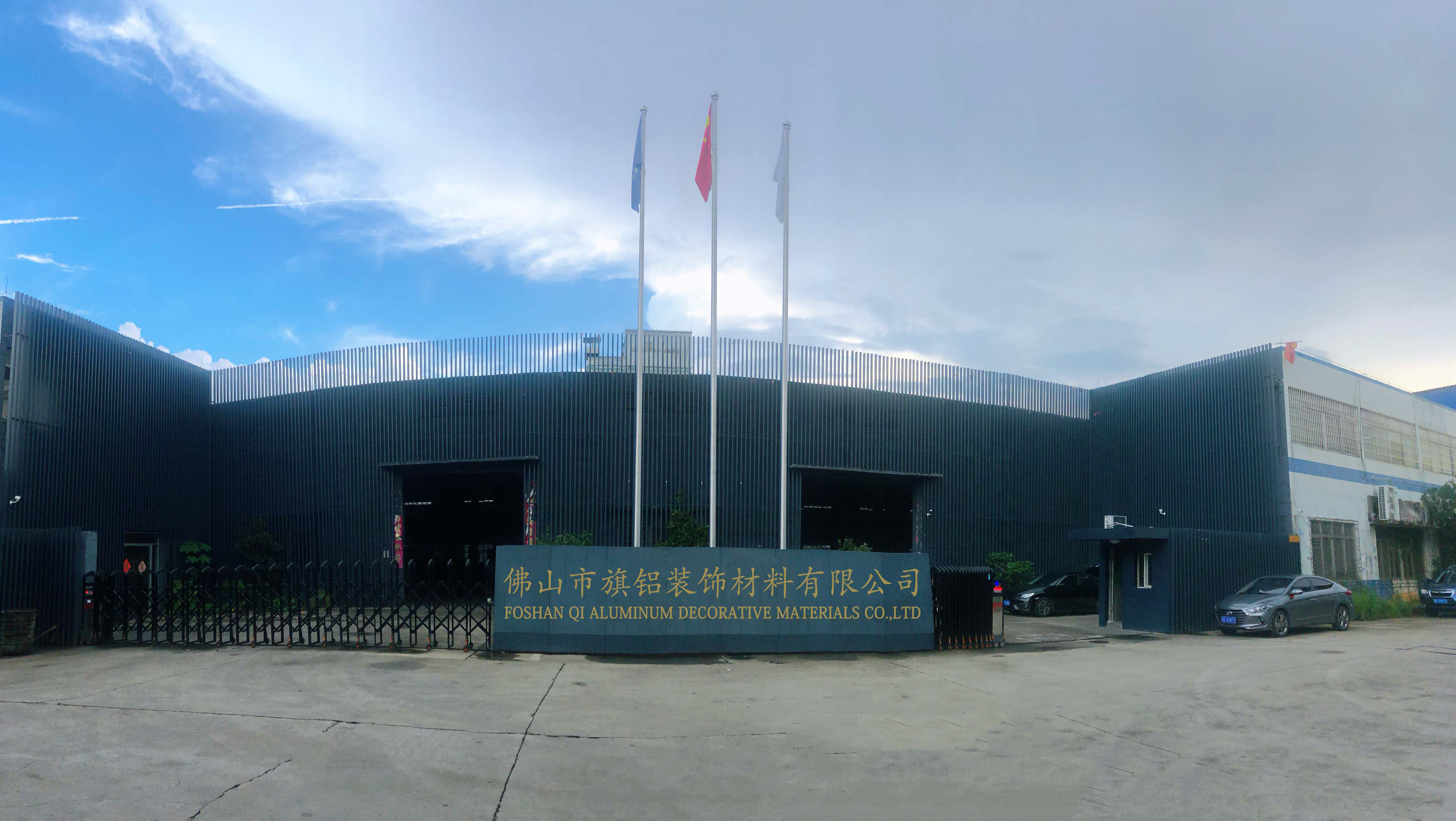

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!