Description

Aluminum Wave Perforated Panels: A Symphony of Form and Function

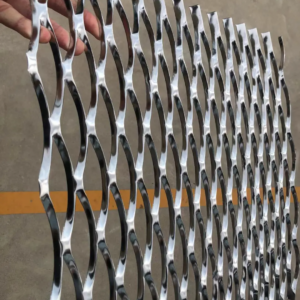

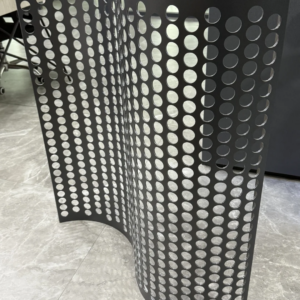

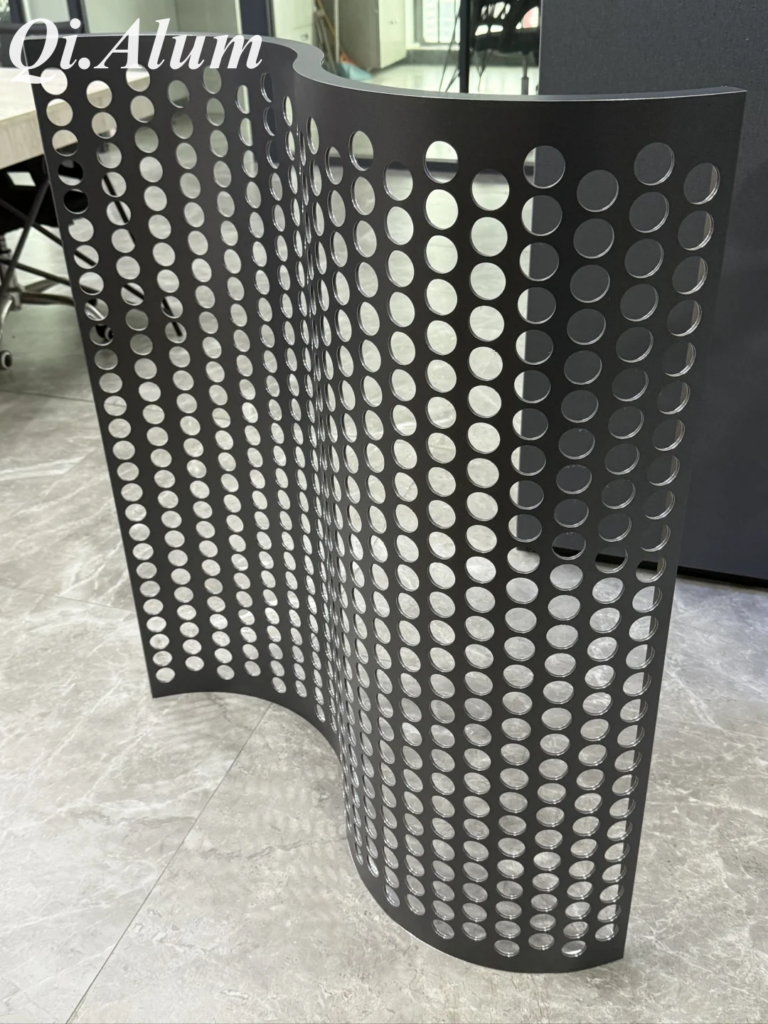

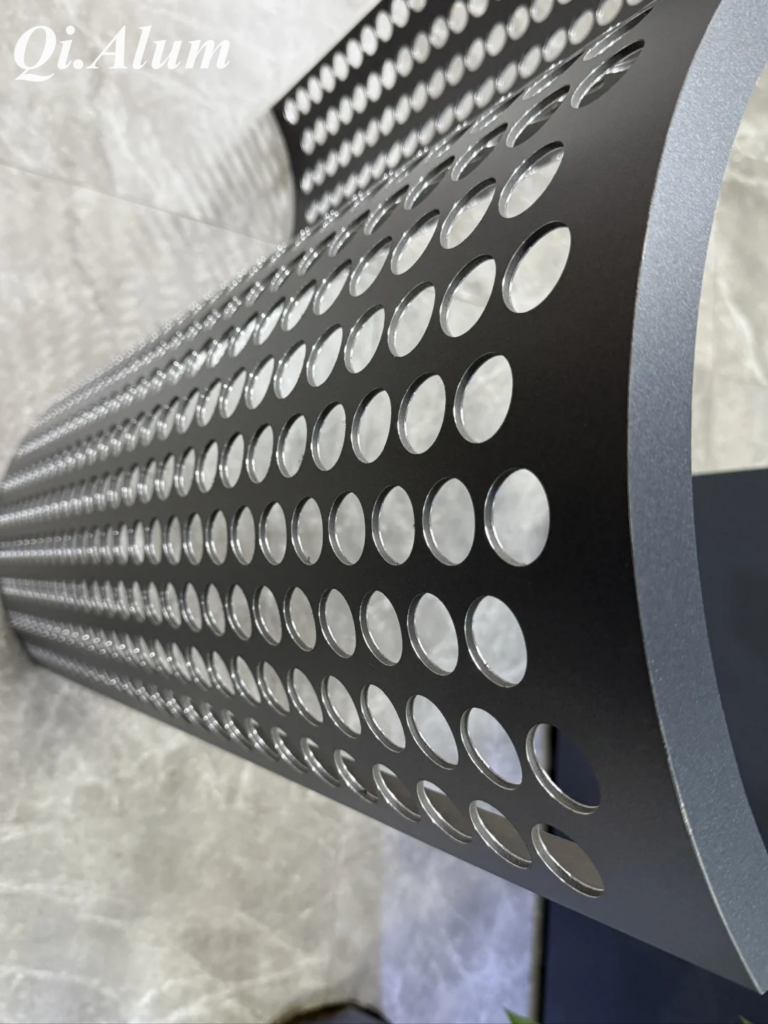

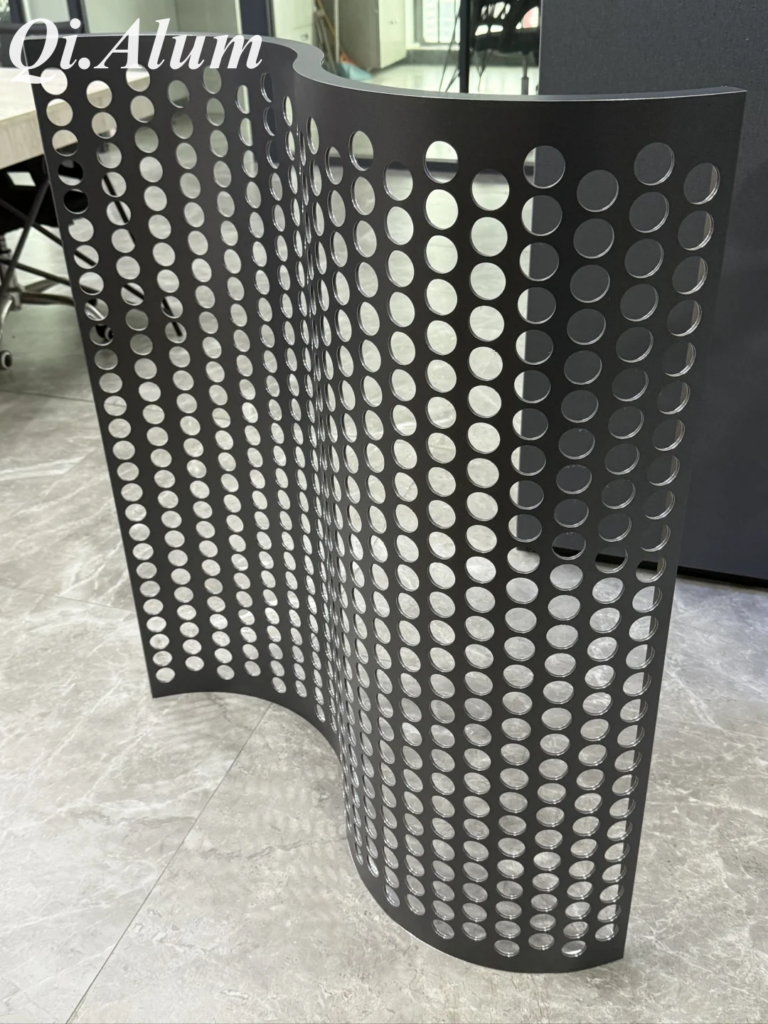

Aluminum wave perforated panels, crafted from high-strength aluminum alloys (e.g., 6061, 3003), are revolutionizing architectural and industrial design with their dynamic aesthetics and versatile performance. These panels feature a corrugated or undulating surface with precision-engineered perforations, combining visual appeal with functional benefits such as acoustic control, thermal regulation, and natural ventilation.

The production of aluminum wave perforated panels involves advanced techniques to achieve both form and function:

- Material Selection: High-purity aluminum alloys are chosen for their lightweight properties (1.5–3mm thickness) and corrosion resistance, with 6061 offering superior strength for structural applications.

- Wave Formation:

- Roll Forming: Sheets are passed through rollers to create consistent wave patterns, ideal for large-scale projects.

- Press Braking: Custom bends and curves are achieved using hydraulic presses, enabling intricate designs.

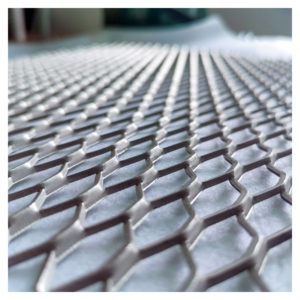

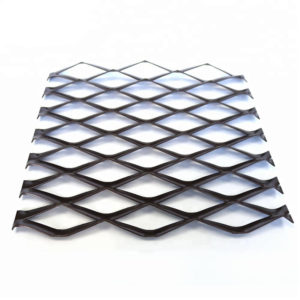

- Perforation Techniques:

- CNC Punching: High-speed machines create uniform holes (0.5–3cm diameter) with precise spacing, ensuring structural integrity.

- Laser Cutting: Used for complex or irregular patterns, offering micron-level accuracy.

- Surface Treatment:

- Anodizing: Enhances corrosion resistance and provides a matte finish.

- PVDF Coating: UV-resistant fluorocarbon coatings (AAMA 2605-certified) ensure color retention and durability in harsh environments.

- Lightweight yet Robust: Weighing 30–50% less than traditional materials like steel, these panels reduce structural load while maintaining high impact resistance.

- Acoustic Performance: Perforations combined with backing materials (e.g., mineral wool) achieve noise reduction coefficients (NRC) of 0.6–0.9, making them ideal for auditoriums and transit hubs.

- Thermal Efficiency: The wave design creates air pockets that improve insulation, reducing energy consumption by up to 20% in buildings.

- Design Flexibility: Customizable wave heights (10–100mm) and perforation patterns (diamond, hexagonal, random) allow for creative expression in facades, ceilings, and partitions.

- Architectural Facades:

- Dynamic Façades: Used in high-rise buildings (e.g., Shanghai Tower) to create kinetic light effects as sunlight filters through perforations.

- Sustainable Design: Integrated with solar panels or green walls for energy-efficient, eco-friendly structures.

- Interior Design:

- Acoustic Baffles: Installed in offices and conference rooms to minimize reverberation.

- Decorative Screens: Add visual interest while maintaining privacy in hotels and retail spaces.

- Industrial Use:

- Ventilation Systems: Perforations enable airflow in factories and data centers.

- Safety Guards: Corrugated profiles enhance impact resistance in machinery enclosures.

The global aluminum wave perforated panel market is projected to grow at a CAGR of 8.2% from 2024 to 2030, driven by:

- Sustainability Demands: Recyclable aluminum content (up to 95%) and energy-efficient designs align with green building certifications (LEED, BREEAM).

- Technological Advancements: AI-driven parametric design tools allow architects to simulate light and airflow patterns before production.

- Regional Growth: Asia-Pacific dominates production (65% share), while Europe and North America lead in innovative applications.

- Chuncheon Lake Observatory, South Korea: Curved wave panels with water droplet-shaped perforations create a shimmering effect, symbolizing the lake’s ripple patterns .

- Biodiversity Pavilion, Brazil: Wave-shaped perforated aluminum cladding responds to environmental conditions, adjusting airflow and shading dynamically .

Aluminum wave perforated panels exemplify the fusion of aesthetics and functionality. Their ability to transform spaces while delivering acoustic, thermal, and structural benefits positions them as a cornerstone of modern design. As manufacturing technologies evolve and sustainability becomes paramount, these panels will continue to redefine architectural possibilities.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!