Description

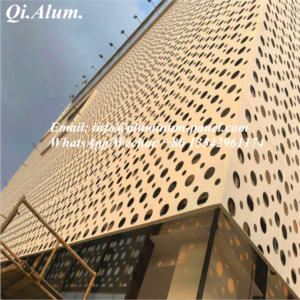

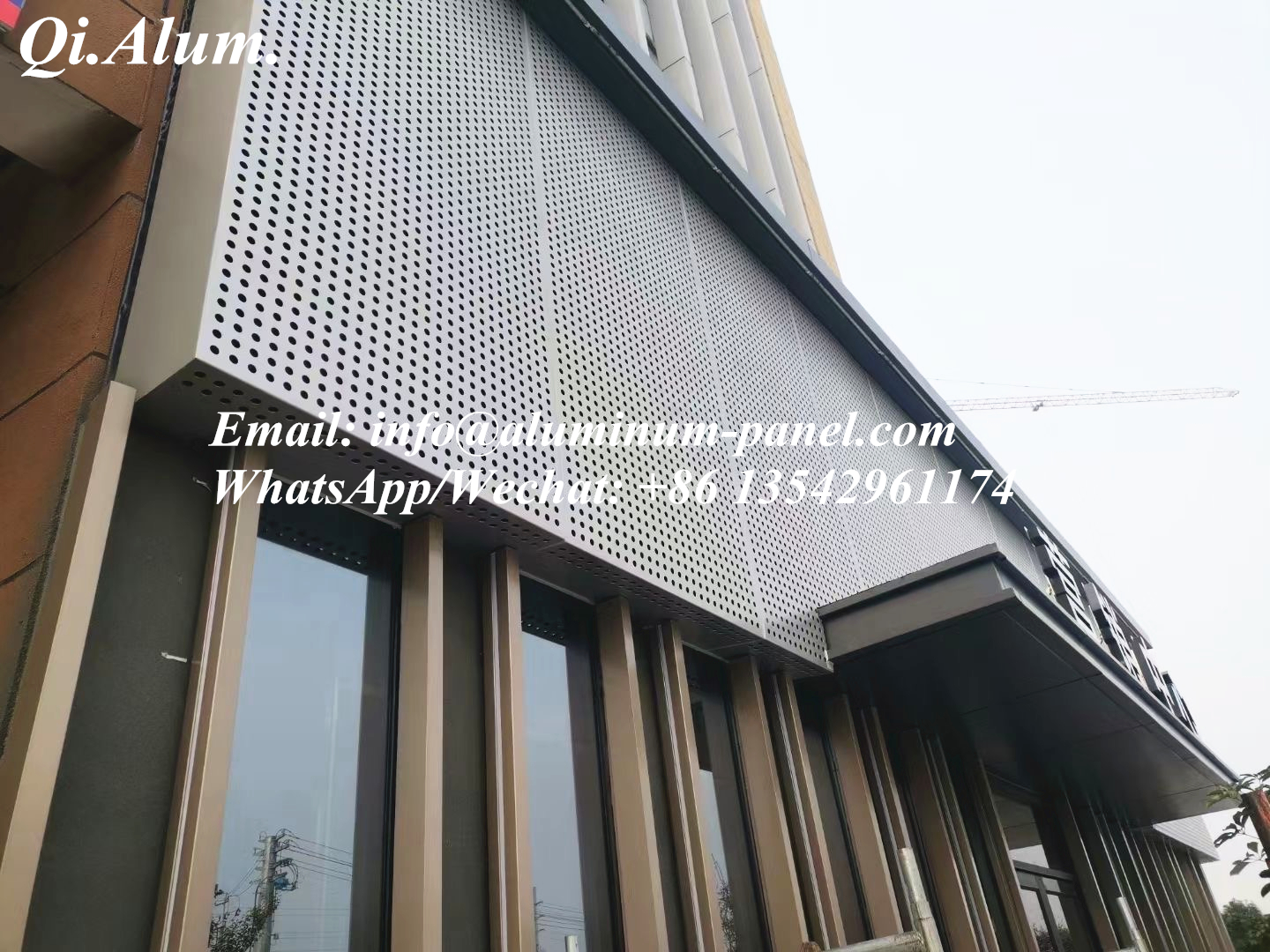

Perforated aluminum hole plate aluminum sheet punching panel generally applies to interior ceiling decoration or exterior curtain wall decoration, groove can customize press freedom, usually round Kong Fang hole irregular hole, etc., at present, due to the improvement of the production process perforated aluminum sheet, all kinds of perforated aluminum hole plate products used in all kinds of engineering decoration, especially some computer laser carve patterns or designs on woodwork aluminum sheet punching hole panel, is hot!

Fluorocarbon spraying aluminum sheet punching plate is mainly used for outdoor, also known as curtain wall aluminum sheet, the normal service life is 10-30 years, does not change color.

Polyester aluminum sheet punching plate can be used for outdoor and indoor. Mainly used indoors, the normal service life is 5-15 years, does not change color.

Perforated aluminum hole plate punching rate how will certainly affect the aluminum sheet roughness and strength of the perforated hole plate, punching process is mainly done in the process of aluminum sheet metal processing, draw a line through the Angle of attack can be used after carving CNC punching machine for punching operation, sales on the perforated aluminum sheet quotation, will have to understand the actual punching rate of aluminum sheet punching panel proportion is much more appropriate.

Be sure to know the concept of punching rate before operation, because the number of punching rate and the size of each hole will affect the quality of punching aluminum panel, punching requirements usually according to the customer set hole size to calculate punching rate, punching rate = punching area/made of aluminum sheet surface area. Popular meaning is the setting of the distance between each hole, that is, the density of the plate face, a reasonable punching rate can make the punching aluminum veneer beautiful and generous, and does not affect the overall flatness and strength.

Hollow aluminum sheet punching hole plate parameters:

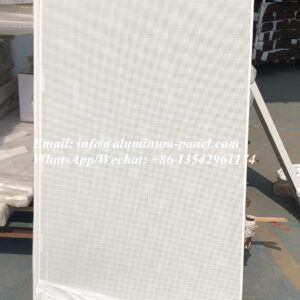

Sheet thickness: 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm

Surface technology: electrostatic powder spraying, heat transfer printing wood grain, polyester paint spraying, fluorocarbon paint spraying, stone grain, imitation copper, wire drawing, etc.

Punching processing can be die stamping processing, long punching, CNC punching, laser engraving punching, however, laser engraving punching although the quality is good, but the cost is slightly higher. Conventional punching generally with mold stamping, generally even if the new mold, relative to laser punching also cost-effective. Punching aluminum veneer punching plate can be flat aluminum veneer, special-shaped aluminum sheet, modeling aluminum panel, but it is generally not recommended to be too complex, too complex process, the cost is naturally high. Also, it’s not easy to install.

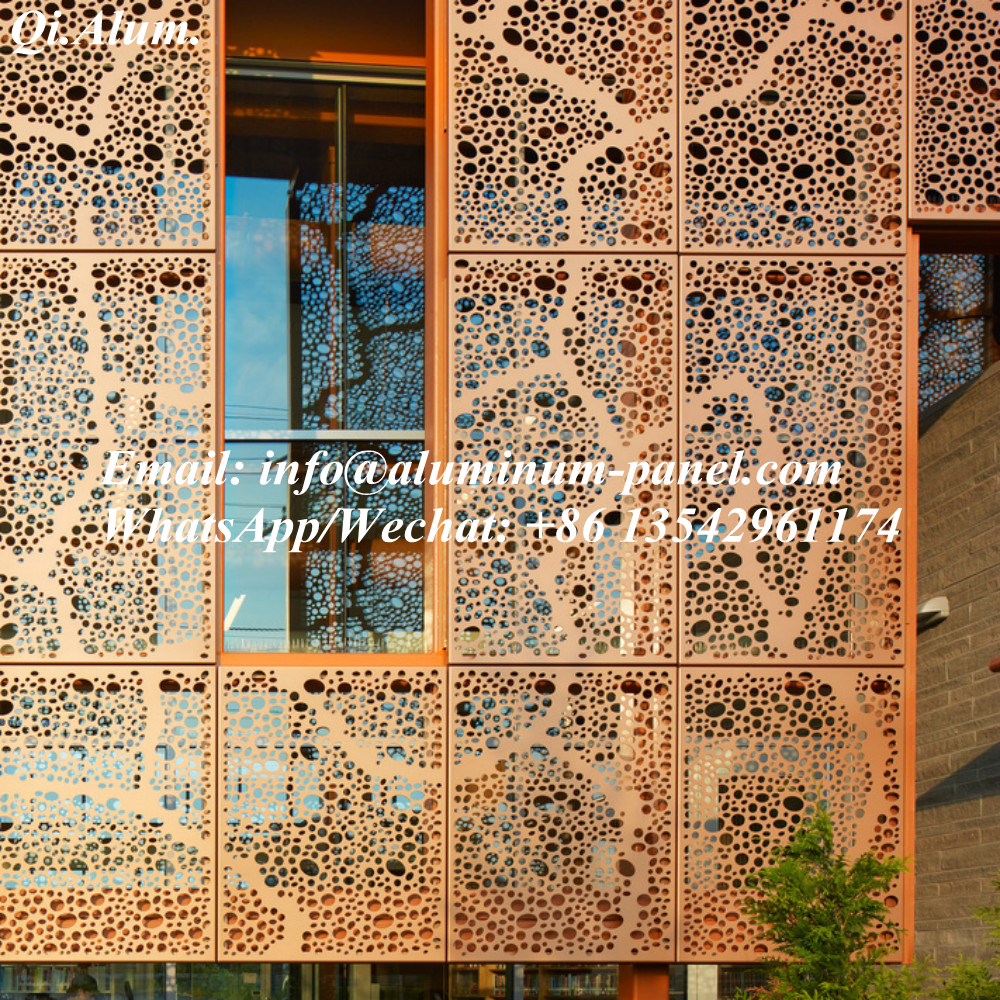

Curtain wall aluminum panel punching hole plate has unique texture, rich color and lasting, and can be diversified in appearance shape, and can be perfectly combined with glass curtain wall material and stone curtain wall material.

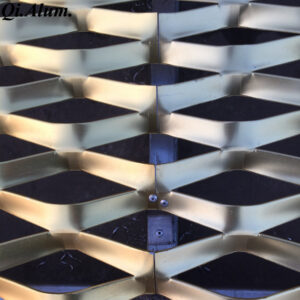

Aluminum sheet punching hole plate can be customized according to demand, such as long hole, square hole, diamond hole, plum hole and so on, has a strong artistic flavor, show personality charm.

Hole hole aluminum sheet punching hole plate due to the existence of punching, it greatly weakens the strength and deformation resistance of aluminum plate, so reasonable punching rate can ensure the quality of punching aluminum panel, at the same time, the amount of waste aluminum punching rate is also affect the price of aluminum sheet.

Outdoor punching aluminum veneer curtain wall also uses self-cleaning aluminum hole plate, ceramic aluminum hole plate, anodized aluminum plate, etc. These aluminum plates and fluorocarbon aluminum veneer have the same or more excellent weatherability and other properties.

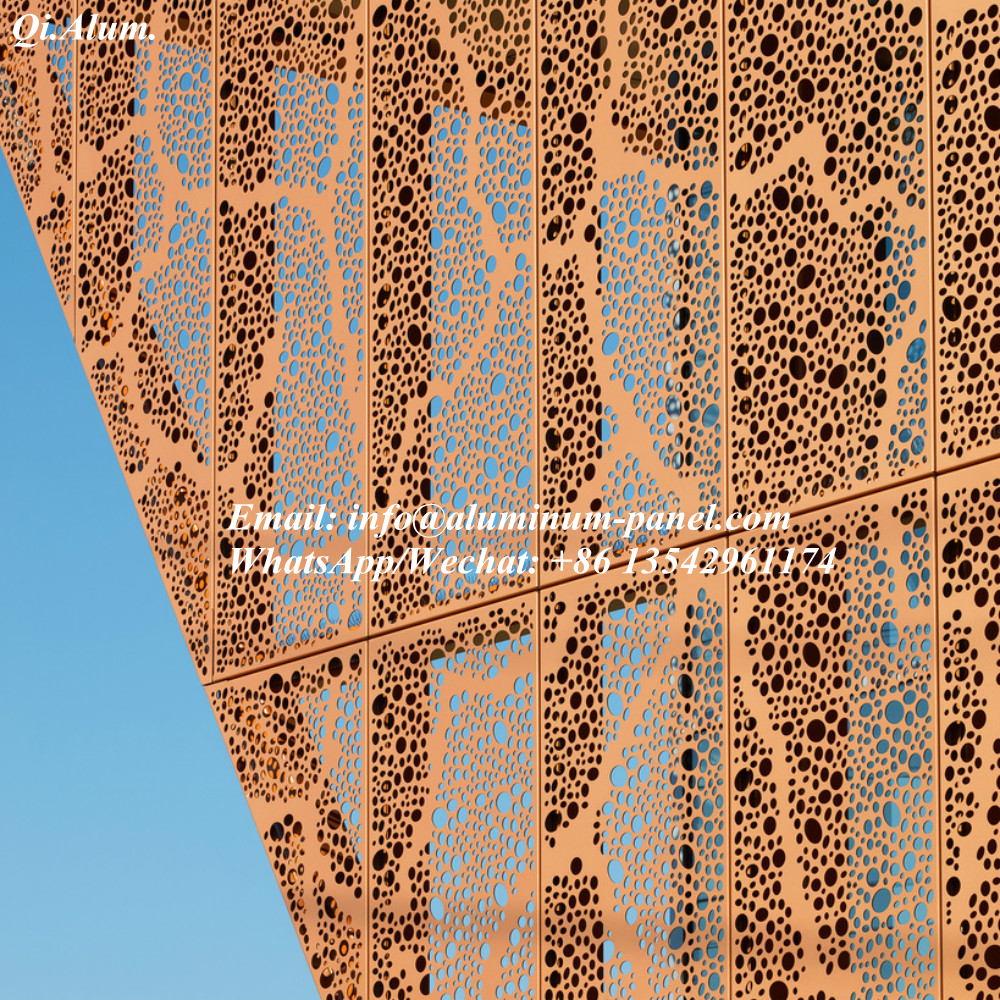

Perforated aluminum veneer punching hole plate through the change of aperture, the arrangement and combination of the density of punching, to create a curtain wall like picture scroll, rich in rich artistic atmosphere.

Aluminum veneer punching hole plate has many advantages, simply list a few points. First of all, punching aluminum veneer is also aluminum veneer, because of the existence of holes, so its texture is relatively light compared with other types of aluminum veneer. Secondly, it is not only beautiful in shape, but also has the advantages of high temperature resistance, corrosion resistance, fire prevention and moisture resistance. Again, a variety of holes and different arrangement, beautiful shape, decorative effect is very good. It also moderately reduces noise, mainly due to the presence of holes that allow sound waves to pass through, thus reducing the intensity of sound.

If it is perforated aluminum veneer curtain wall perforated aluminum hole plate considering the long-term exposure to the outside, fear a rub off, craze, and other issues, advising clients to choose fluorine-carbon aluminum single sheet, fluorine-carbon aluminum single sheet punching plate, aluminum alloy sheet is used for the base material, after CNC bending technologies such as molding, spray painting of a kind of new wall materials.

Generally speaking, there are three main factors affecting the sound insulation effect of aluminum veneer punching plate:

1, the air density of the aluminum veneer itself is good;

2, the use of fluorocarbon aluminum veneer specifications are appropriate;

3 Aluminum veneer installation quality.

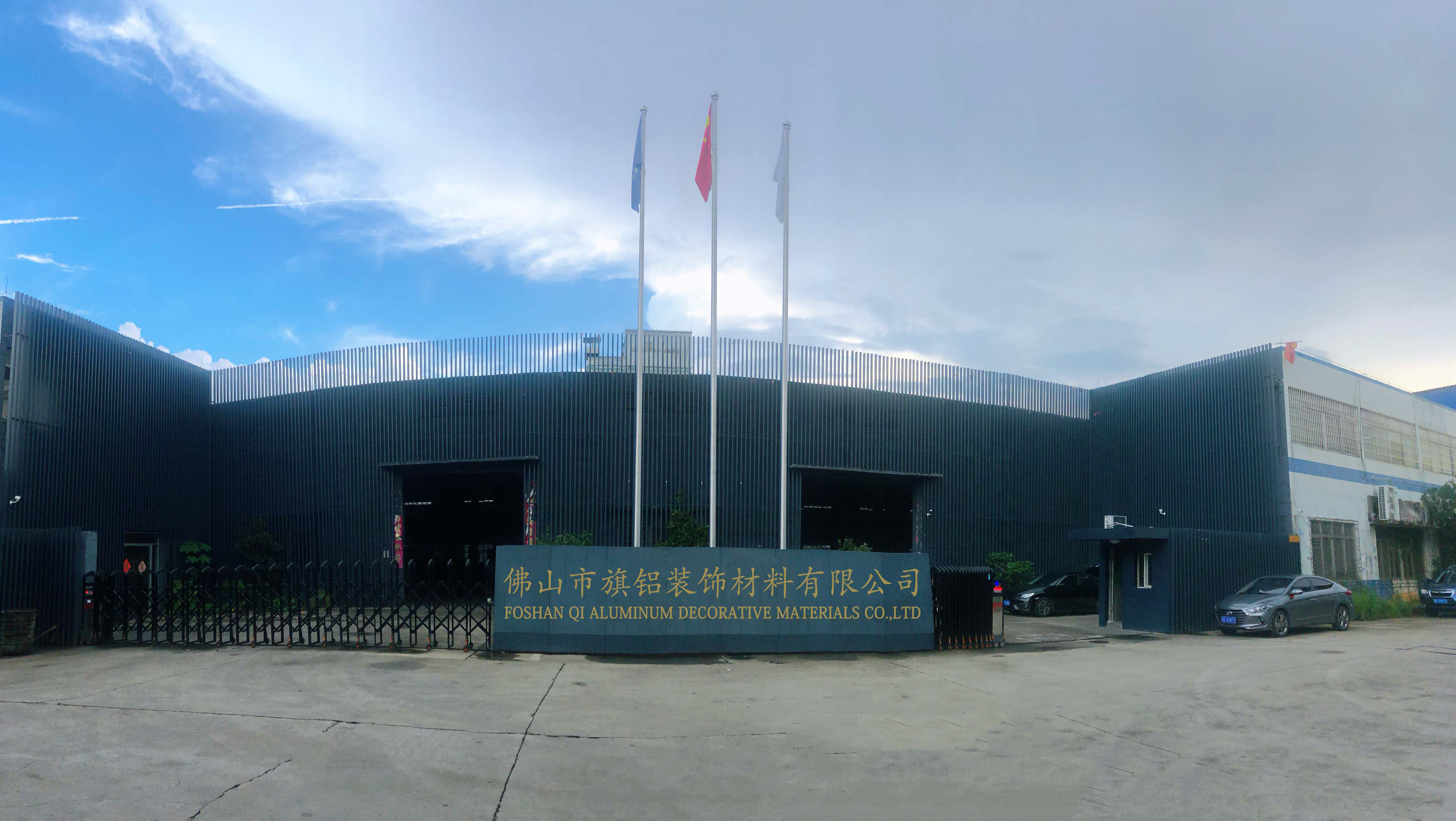

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!