Perforated aluminum panel belongs to a category of aluminum panel , the main decorative, may be a lot of people don’t understand in the past, with the development of social economy, the improvement of living standards, perforated aluminum panel installation method generally consistent with that of ordinary aluminum panel installation, but higher request of aluminum panel , consider the accuracy of spelling after guarantee adornment effect. The following is the installation process of punching aluminum panel :

- Release line

Secure the skeleton and spring the skeleton back to the base. The skeleton is fixed on the main structure. Check the quality of the main structure before releasing the cable.

- Secure the skeleton of the connector

Weld the connector holder to the column of the main structure.

- The perforated aluminum panel is installed and the frame is fixed

The skeleton is precorroded. The mounting skeleton is positioned accurately and firmly combined. Check center line and surface elevation after installation. To ensure the accuracy of plate installation, it is recommended to Pierce the mullion with a theodolite. The deformation joint, settlement joint and variable section are properly treated to meet the requirements.

- Install perforated aluminum panel

Punching aluminum panel installation is firm and reliable, simple and easy.

1, the gap between the plates should be processed internally to make it smooth and smooth.

2, punching aluminum panel installation, easy to be polluted parts, covered with plastic film or other materials protection.

- Related construction

- Check whether the perforated aluminum column meets the standard.

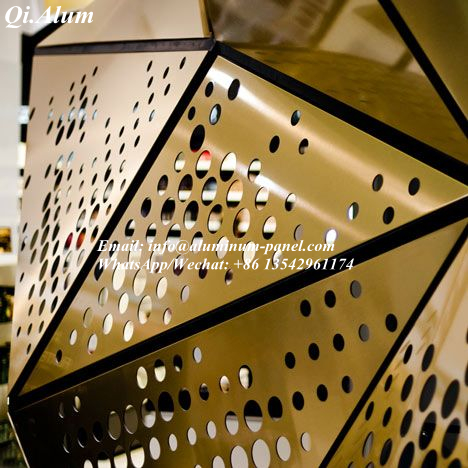

In recent years, punching aluminum panel has different uses according to its quality and aperture size. Users should design the size of holes according to their own conditions and engineering needs. The punching rate of punching aluminum panel determines the density of the pattern on the panel. Punching too dense will lead to the reduction of the pressure resistance of aluminum panel , which is not easy to process, and punching too wide will cause not beautiful and lack of artistic feeling. Therefore, different occasions should choose different aluminum perforated panel.

Industry insiders say that punching aluminum panel is light in weight, good in rigidity, high in strength, good in manufacturability, uniform in coating, diverse in color, convenient in installation and construction, fast in speed, good in weather resistance and corrosion resistance, easy to clean and maintain. Because this got the welcome of numerous building materials manufacturer and user.

With the development of architectural decoration industry, perforated aluminum panel is widely used in high-rise buildings because of its excellent corrosion resistance, strong uv resistance and fading resistance. At the same time, metal because of its rich color choice, burnish is good, resist the advantage such as impact sex is strong, get the favour of building adornment stylist more and more, be widely used at project adornment condole top and metope.

However, users need to pay attention to that, as a high-end decorative material, the production and processing level of the main domestic aluminum panel manufacturers are very different. Before placing an order, we should pay special attention to the inspection of the manufacturer, inspect their production capacity and scale. Project performance, etc., depends on its technical design ability. Do not just look at the low price of punching aluminum panel, but to choose those smaller processing plants. This will not only bring greater difficulties to construction and management, serious consequences may also cause irreparable economic losses.

Curtain wall material manufacturers almost cover aluminum panel and aluminum honeycomb panel related products, including powder aluminum panel , painted aluminum panel , interior wall aluminum panel and aluminum curtain wall aluminum panel and 2mm-3mm aluminum panel . The main products are: fluorocarbon aluminum panel , dense aluminum panel , subway aluminum panel , construction aluminum panel , punching aluminum panel , carved fluorocarbon aluminum panel, perforated aluminum panel , double-curvature fluorocarbon aluminum panel , coated fluorocarbon aluminum panel, built-in wood grain aluminum panel , etc. It is widely used in airports, subways, hotels, office buildings, shopping malls, hospitals, residential buildings and other home decoration work.