Description

The processing and production process of aluminum honeycomb panels is as follows:

- Preparation of Raw Materials: Aluminum honeycomb panels are typically made from aluminum alloy or pure aluminum material. The raw materials are prepared by cutting aluminum coils into sheets of specified sizes.

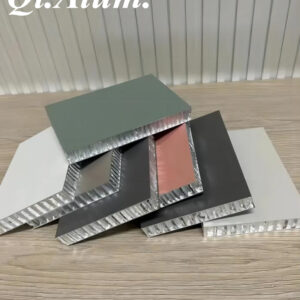

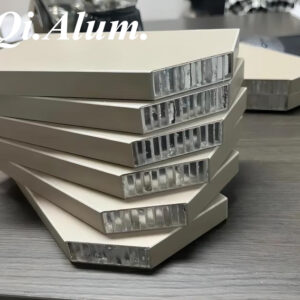

- Honeycomb Core Production: The aluminum sheets are then processed through a honeycomb core production line. This involves expanding and bonding the aluminum sheets to create a honeycomb structure. The honeycomb core provides the panel with strength, rigidity, and lightweight properties.

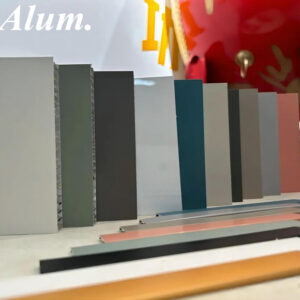

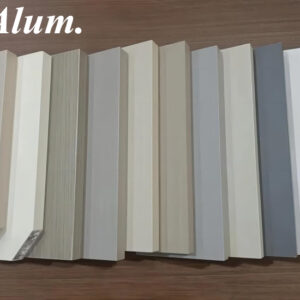

- Surface Treatment: After the honeycomb core is produced, the surface of the aluminum sheets may undergo various treatments such as coating, anodizing, or painting to enhance corrosion resistance, aesthetics, and durability.

- Panel Bonding: The honeycomb core is then sandwiched between two aluminum sheets to form a complete aluminum honeycomb panel. The bonding process typically involves using adhesives or thermal bonding techniques to ensure strong adhesion between the layers.

- Cutting and Shaping: The assembled aluminum honeycomb panels are cut and shaped according to the desired dimensions and specifications. This may involve cutting the panels into specific sizes and shapes using CNC machines or other cutting equipment.

- Quality Control: Throughout the production process, strict quality control measures are implemented to ensure that the aluminum honeycomb panels meet the required standards and specifications. This includes inspecting the raw materials, monitoring the production process, and testing the finished panels for strength, durability, and dimensional accuracy.

- Packaging and Shipping: Once the aluminum honeycomb panels pass quality control checks, they are packaged securely to prevent damage during transportation. The panels are then shipped to customers or construction sites for installation.

Overall, the production process of aluminum honeycomb panels involves several steps, including raw material preparation, honeycomb core production, surface treatment, panel bonding, cutting and shaping, quality control, packaging, and shipping. Each step is crucial in ensuring the quality, performance, and reliability of the finished panels.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report, if there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation, but shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience,We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!