Description

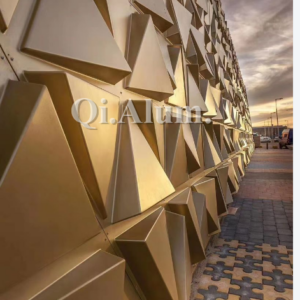

Aluminum Hyperbolic Panels: Precision-Engineered Solutions for Modern Architectural Cladding

Meta Description: Discover high-performance aluminum hyperbolic panels—parametric design flexibility, LEED-compliant sustainability, and unmatched durability for curved facade systems.

Revolutionizing Architectural Surfaces with Hyperbolic Geometry

Aluminum hyperbolic panels represent the pinnacle of parametric design and advanced material engineering, enabling architects to transform visionary curves into buildable reality. These 3D-formed panels combine mathematical precision with industrial-grade performance, offering:

- Ultra-tight bending radii (from 150mm) for fluid organic forms

- Weight reduction of 60-70% vs. traditional curved cladding materials

- Seamless BIM integration through AI-optimized CAD/CAM workflows

Core Technical Advantages

1. Aerospace-Grade Material Science

- Alloy Composition: 5052-H32 / 6061-T6 marine-grade aluminum

- Surface Treatments:

- PVDF-FEVE hybrid coating (30-year fade/chip resistance)

- Anti-fingerprint nano-coating options

- Custom anodized finishes (100+ RAL/PMS colors)

2. Climate-Adaptive Performance

| Parameter | Specification |

|---|---|

| Solar Reflectance Index | 0.89 (Exceeds ASHRAE 90.1-2022) |

| Thermal Expansion Rate | 23.4 μm/m·K (±0.5% variance) |

| Wind Load Resistance | Up to 75 m/s (Type 4 hurricane) |

| Operating Temperature | -50°C to +150°C stable |

3. Sustainable Manufacturing

- Recycled Content: 92% post-industrial scrap (SGS-certified)

- Carbon Footprint: 8.7 kg CO₂/m² (EPD International verified)

- End-of-Life Recovery: 100% closed-loop recyclability

Design & Engineering Capabilities

- Parametric Modeling Support:

- Free Grasshopper/Rhino plugin for curvature optimization

- Real-time FEM (Finite Element Method) structural analysis

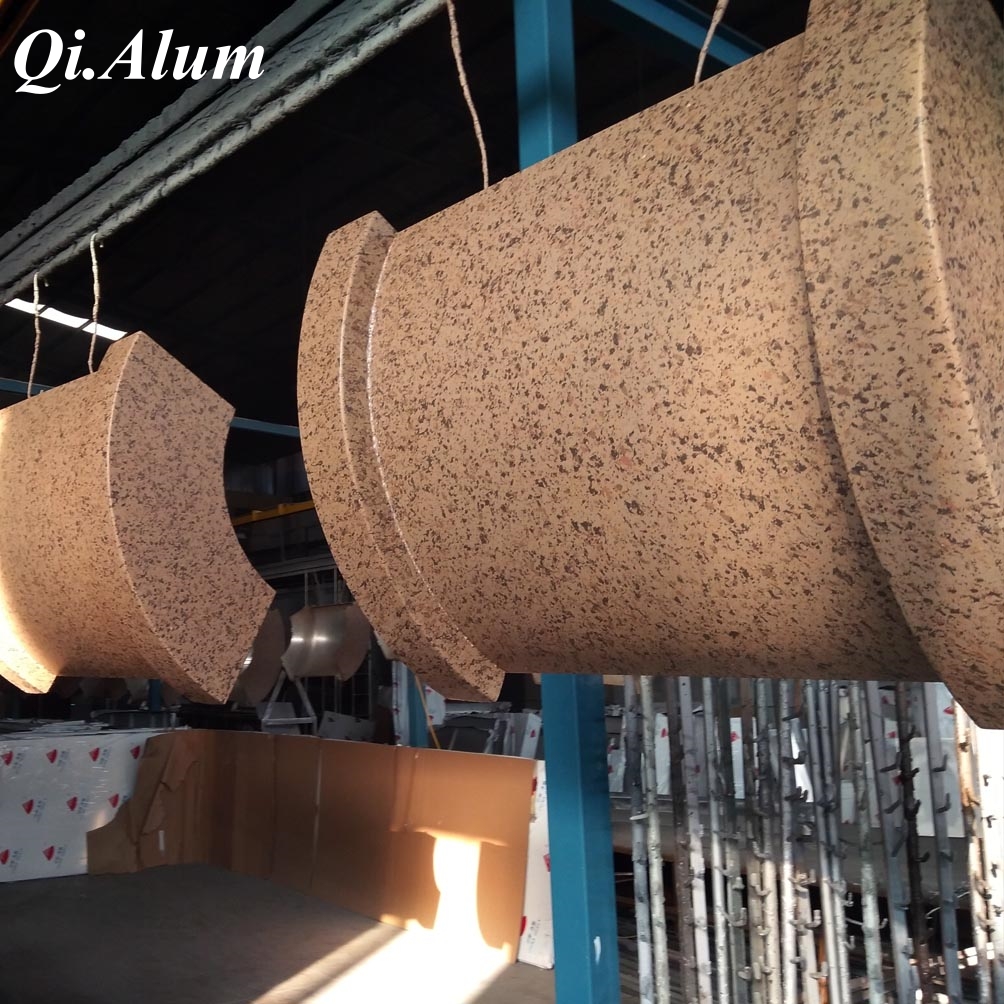

- Precision Fabrication:

- 5-axis CNC robotic bending (±0.3mm tolerance)

- Laser-etched alignment markers for error-free installation

- Smart Panel Systems:

- Integrated LED channel options

- Acoustic damping layers (NRC 0.75 rating)

- Photovoltaic-ready surfaces

Industry Applications

| Sector | Key Requirements | Our Solution |

|---|---|---|

| Urban High-Rise | Wind-resistant lightweight cladding | 4.2 kg/m² panels with A2 fire rating |

| Cultural Spaces | Complex free-form geometries | 0.5mm tolerance parametric kits |

| Transport Hubs | Anti-corrosion for harsh climates | Salt-spray certified coatings |

| Retail Facades | Brand-specific color matching | Digital print + anodizing combos |

Frequently Asked Questions (FAQ)

Q1: How long is the lead time for custom panels?

A: Standard orders: 15–30 days. Rush orders: 10 days (surcharge applies).

Q2: Can panels be repaired if damaged?

A: Minor dents can be field-repaired; severe damage requires panel replacement.

Q3: Are curved panels more expensive than flat ones?

A: Initial costs are higher, but savings in installation and maintenance offset the difference.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!