Description

Carved aluminum panel characteristics: 1, light weight, good rigidity, high strength 3.0 mm thick aluminum plate to 8 kg per square plate, tensile strength of 100-280 n/mm22, good durability and corrosion resistance.

The kynar – 500, hylur500 for the PVDF fluorocarbon lacquer, the available leg color in 25 years.

3, good in usability.

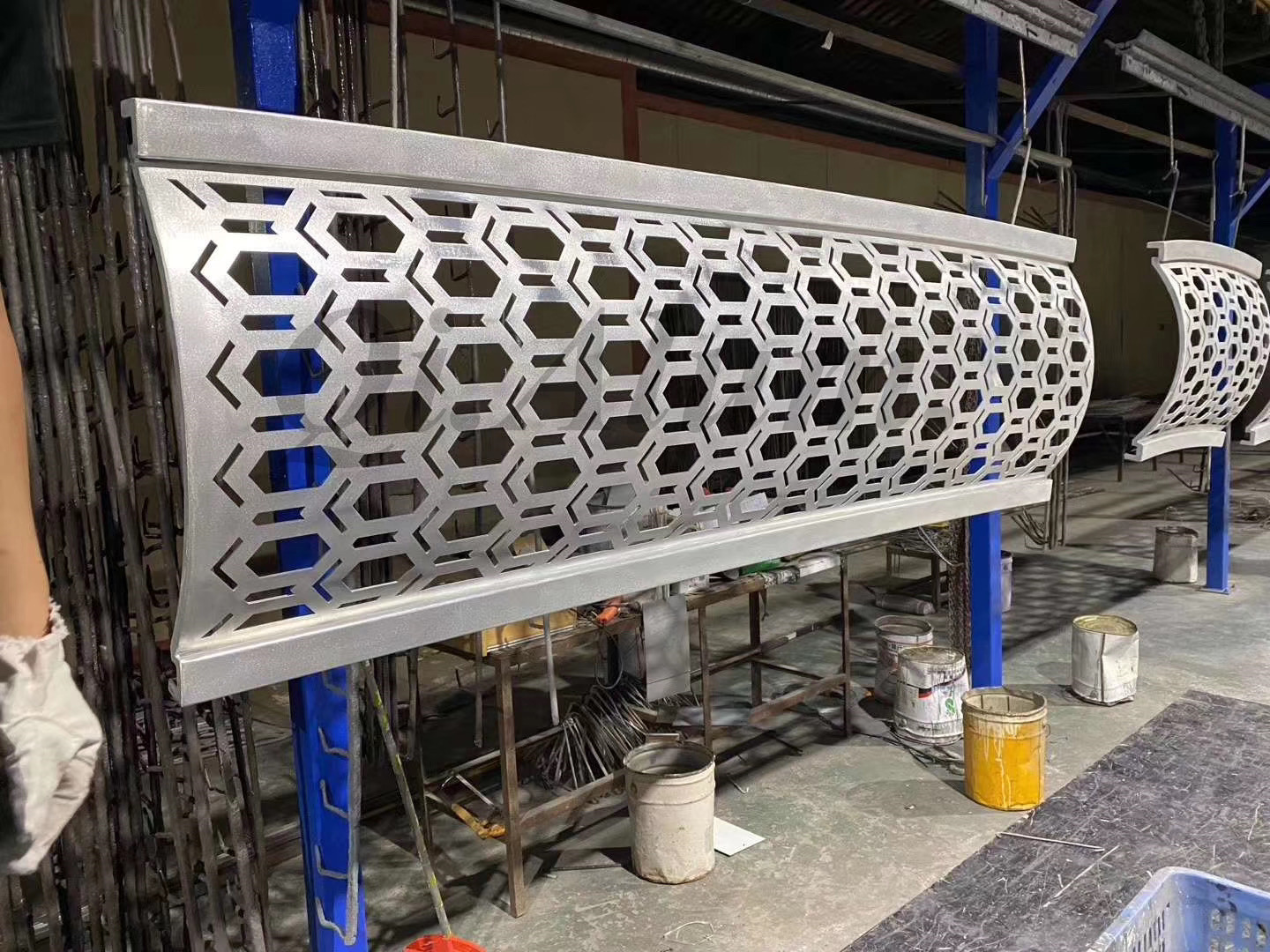

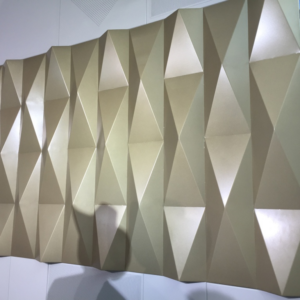

Using spray painting process after processing first, aluminum plate can be processed into plane, arc and spherical all kinds of complicated geometry.

4, uniform coating, color diversity.

Advanced electrostatic spraying technology makes the paint and the adhesion between aluminum plate uniform, color variety, choose space is large.

5, and defile not easily, easy cleaning and maintenance.

Fluorine coating film of viscosity, the surface is very difficult to attached pollutants, have good to clean sex more.

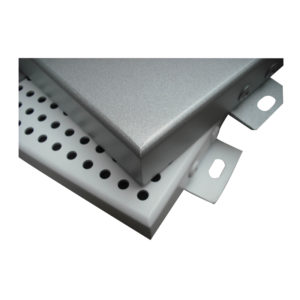

6, installation, construction convenient and quick.

Aluminum molding in the factory, construction site without cutting, can be fixed on the frame.

7, can be recycled, is better for the environment.

Aluminum plate can be 100 %, different from the glass, stone, ceramic, the adornment material such as aluminum, high recycling salvage value.

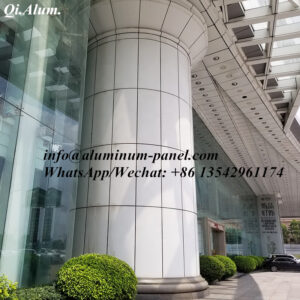

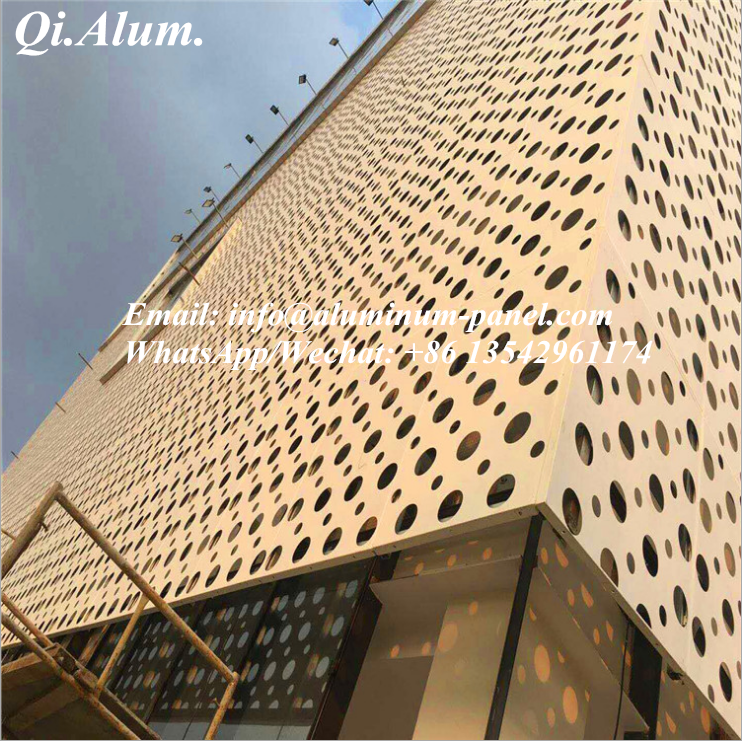

Use scope: building metope adornment, indoor screen, villa, villa, club house, house decoration, kitchen, bathroom, living room, etc.

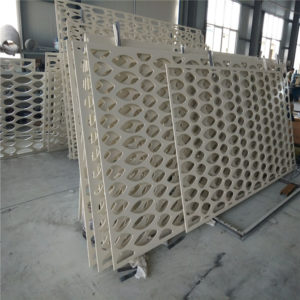

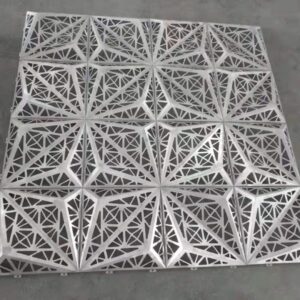

Punching Sheet Hole:

Rectangular hole , Square hole , Diamond hole , Hole , Hexagonal hole , Cross hole , Triangle hole , Long hole , Along waist hole , Plum blossom hole , Scale hole , Hole Pattern , Star shaped holes , Irregular holes ,Drum hole etc,

Surface Treatment Process:

Skim →Alkali-Corrosion → Blare-elimination(by acid) →Chromiumizing → Drying → Parts-installation →Spraying Solidifying → Parts- removing → QC& Packing

Fabrication Process:

Sheet Metal Cutting- CNC Cutting(Punching,Laser Cutting-Hollow out)- Bending- Welding-Bracket Fixing-Polishing-Surface Treatment- QC-Package

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence :

Decorative Living Room, Hotel, Bar, etc.

Indoor and outdoor public space backdrop, Elevator cabin, handrail,living room, background wall, ceiling, Kitchen equipment.

Specially for bar,club,KTV,hotel,bath center,villa,shopping mall

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

Projects list:

Perforated Sheet FAQ

Q: Can perforated sheet be plastic coated?

A: We don’ t plastic coat perforated sheet, however we can perforate a plastic sheet.

Q: Why is perforated sheet protected with a thin layer of oil?

A: Lubricating oil is used to reduce the friction during the perforating process.

Q: Can perforated sheet be formed after perforating?

A: We can shear and form perforated sheet to any specification needed.

Q: What opening types are most common in perforated sheet?

A: Round, rectangular, and slotted perforated sheet are very popular options. See our decorative perforated sheet for more unique styles.

Q: Which perforated sheet materials are rust resistant?

A: Perforated aluminum, stainless steel, and galvanized perforated steel are the most rust resistant materials that we perforate.

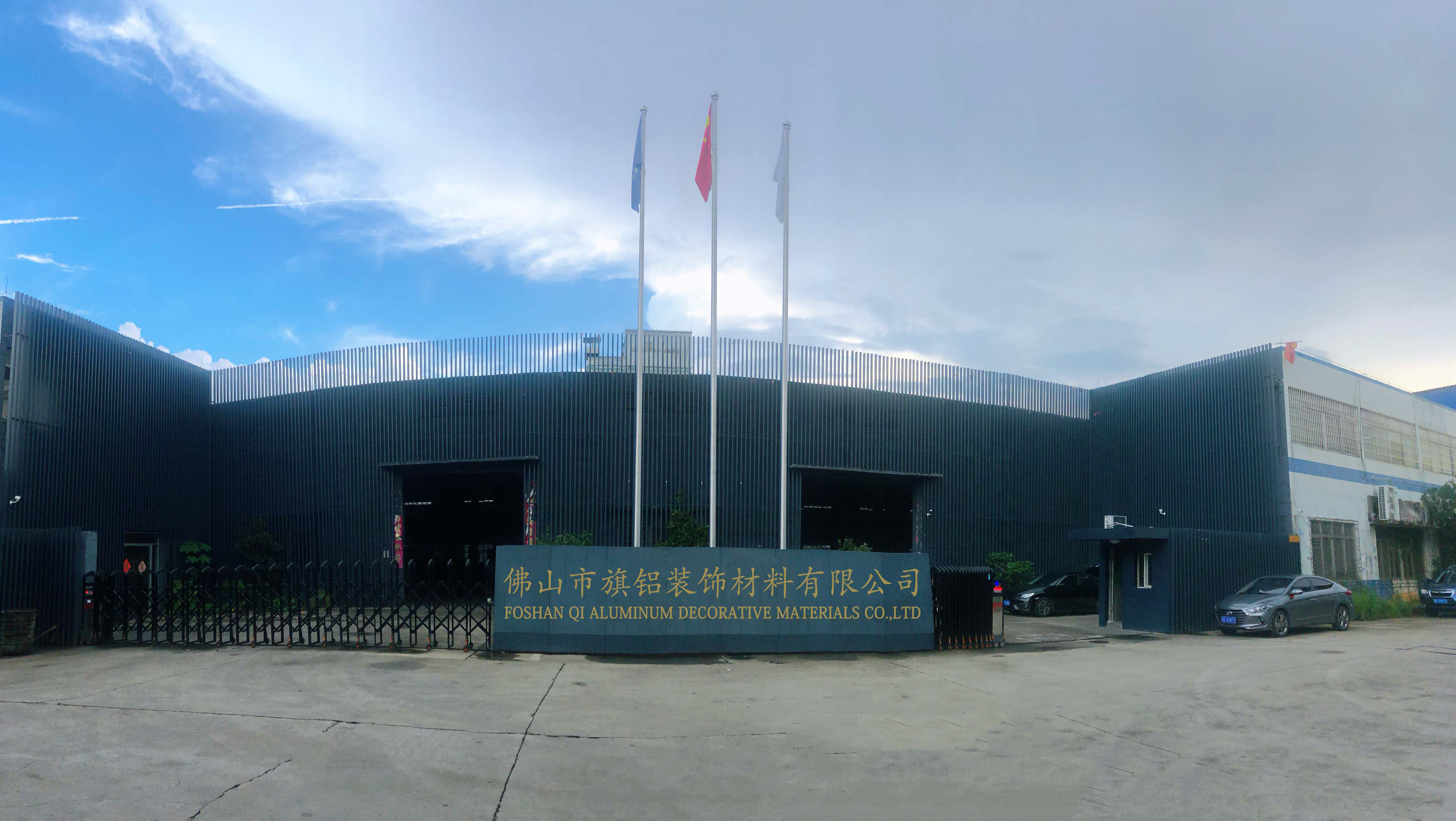

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!