Description

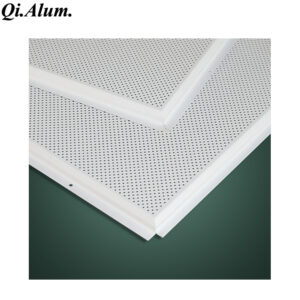

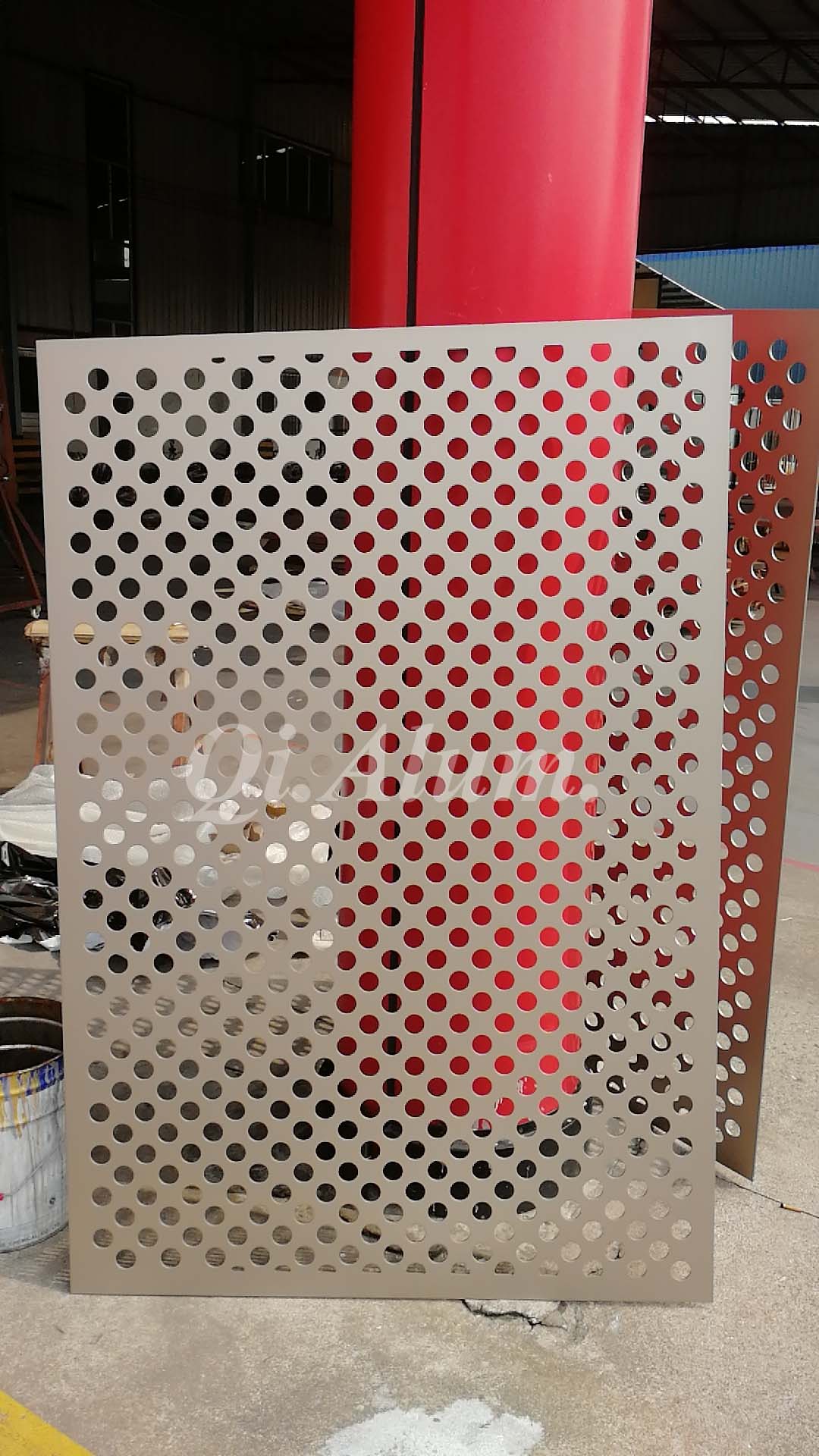

China Good Price Aluminum Laser Cut Carved Ceiling Decorative Sheets Manufacturer

Applications:

Facades, Balustrade Infills,Decorative Panels, Ceiling Tiles,

Partitions

Extra Notes:

Other materials and thickness can

be manufactured upon request.

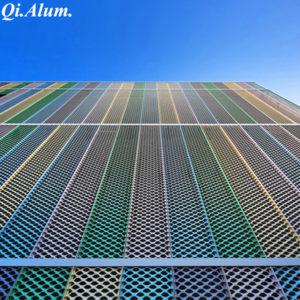

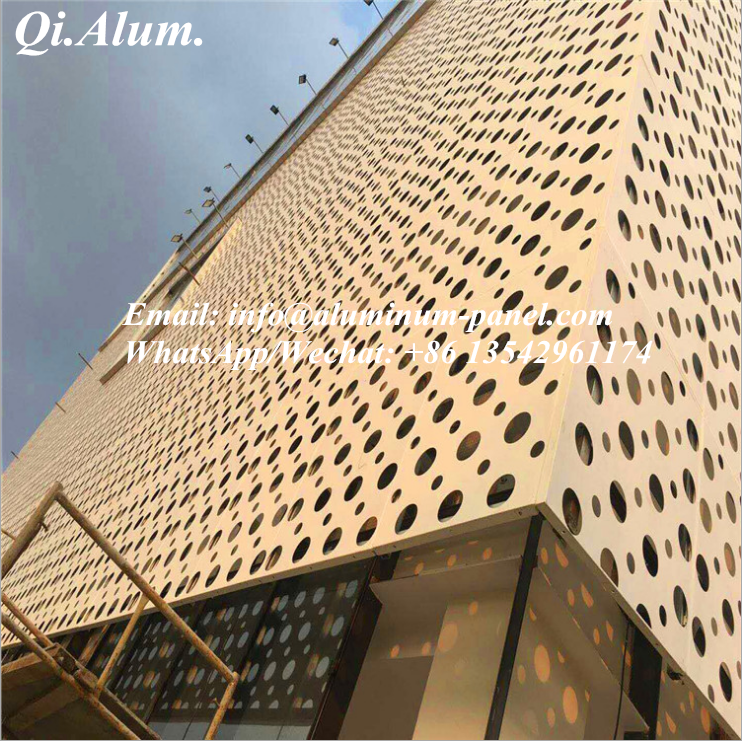

Exterior Aluminum Panels Metal Perforated Sheet with CNC Laser Cut Pattern used for façade curtain wall, sun screen, handrail, interior decoration, screening. It can be hollowed according to your sample or CAD drawing. It can also be folded, curved according to request. These metal laser cut panels are not only a modern and stylish renovation for your outdoor area and decorative indoor room area, but also versatile that can save your both time and money for choice decorative building materials.

Surface treatment:

The Surface is coated with PVDF fluorocarbon after chromium treatment, and PVDF paint brand options include PPG, Akzo Nobel, Nippon, Tiger and KCC etc. In our factory, we have approximately 100 colors for your choice and we can match the color according to your preference.

Application:

- Decorative Living Room,Hotel,Bar,etc.

- Indoor and Outdoor Public Space Backdrop,Elevator Cabin,Handrail,Living Room,Background Wall,Ceiling.

- Specially for Bar,Club,KTV,Hotel,Bath Center,Villa,Shopping Mall.

About us

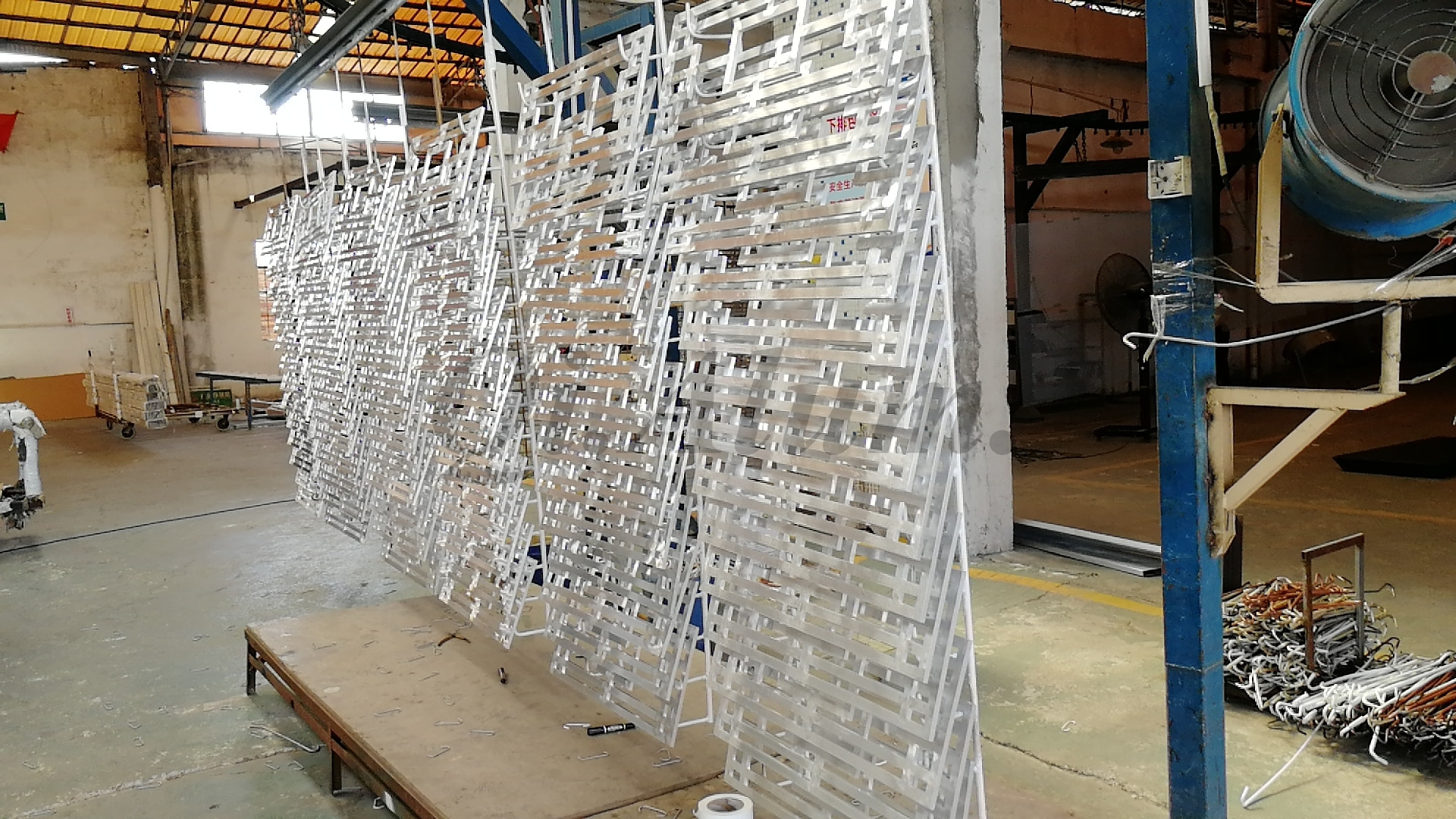

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!

FAQs

What Is Your Term Of Payment?

How Do I Get A Exactly Quotation?

Can You Provide OEM & ODM Service?

How About Your Delivery Time?

How Do You Guarantee Your Products’ Quality?

What Does The Thickness Mean?

What Does The Coating Mean?

Coating is a surface treatment, it will benefits surface effect that crrosion resistance, weather resistance, fungus resistance, highly improved after surface treatments.

laser cut decorative panels will bring a unique design element to your next project. We manufacture in a huge range of materials, powder coated colours, designs and some of the largest panel sizes on the market.

| Surface treatment | PE/PVDF spray coating, Powder coating |

| Painting | PPG, Akzo Nobel, Becker, etc |

| Color | Solid color, Metallic Color, Wooden/Stone Color, etc |

| Size/Design | sizes and design are available according your detail drawings |

LASER CUT PANELS CAN BE MADE TO SUIT ANY JOB

Whether your project is a backyard BBQ area, home renovation or a large commercial facade our team are here to assist in bringing your next project to life.

Features:

1. Good rigidity and environmental resistance

2. UV-resistant, Acid-resistant and alkali-resistant

3. Light wight, easy to install

4. Self-clean and maintenance

5. Sound-insulation

Recommend applying in these places below:

supermarket, marketplace

service station, toll station

underground, air port, bus station

school, office, meeting room

hall, corridor and toilet

sport centre

Product features:

1; Advanced electrostatic spraying technology makes PVDF coating and aluminum panel surface adhesion is stronger and not easy to fall off, the product surface coating is more uniform, color is more colorful, color diversification, a wider range of choices.

2; Using PVDF paint spraying can make PVDF aluminum panel surface more smooth and not easy to stick dust, can effectively reduce the cleaning and maintenance of the product; Its surface layer is difficult to adhere to dirt, with a very good self-cleaning effect.

3; PVDF aluminum panel weight is relatively light, in terms of installation without too many construction personnel. Mild large, good rigidity, even the thickness of 4mm aluminum plate in the weight of only 9KG per square, in the strength can reach 110-300N/mm2

4. The product has corrosion resistance and weather resistance is very good, PVDF aluminum panel can be used in a harsh environment, usually used for curtain wall decoration, the use of PVDF coating can make the product in 30 years do not change color does not decolorize.

5; The products are processed by large NUMERICAL control machine tools and the production process is better. In the use of PVDF paint spraying technology, the surface of the products is very smooth and burr free. In the shape can also be more diverse, can be made into a variety of more complex shapes such as arc ball shape.

6; PVDF aluminum panel is made of high quality aluminum alloy processing, can have resource recycling, very energy saving and environmental protection. Products can achieve 100 percent recycling value, it is different from the traditional ceramic tile, glass, stone materials, recycling value.

7. The product is very convenient in construction and installation. The PVDF aluminum panel is usually customized according to the construction site. There is no need to cut the product at the installation site, and the installation can be directly fixed on the skeleton after the installation.

Application areas:

The application of carved PVDF aluminum panel is very wide, the products can be used for: commercial buildings, high-speed rail, airports, pavilions, museums, as well as some hotels, shopping plazas and other exterior wall decoration or interior decoration.

Sheet metal spraying:

Product packaging:

Packing Details:

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request.

3. Excellent in weather fastness and corrosion resistance.

4. Good fireproof and waterproof property.

5. Even coating, various colors.

6.Easy to process ,easy to maintain.

The container shipping:

Punching Sheet Hole:

Rectangular hole , Square hole , Diamond hole , Hole , Hexagonal hole , Cross hole , Triangle hole , Long hole , Along waist hole , Plum blossom hole , Scale hole , Hole Pattern , Star shaped holes , Irregular holes ,Drum hole etc,

Surface Treatment Process:

Skim →Alkali-Corrosion → Blare-elimination(by acid) →Chromiumizing → Drying → Parts-installation →Spraying Solidifying → Parts- removing → QC& Packing

Fabrication Process:

Sheet Metal Cutting- CNC Cutting(Punching,Laser Cutting-Hollow out)- Bending- Welding-Bracket Fixing-Polishing-Surface Treatment- QC-Package

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence :

Decorative Living Room, Hotel, Bar, etc.

Indoor and outdoor public space backdrop, Elevator cabin, handrail,living room, background wall, ceiling, Kitchen equipment.

Specially for bar,club,KTV,hotel,bath center,villa,shopping mall

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

Projects list:

Q1: What is delivery time? A: 4 weeks days after deposit. Except for public holidays.

Q2: How can you guarantee the quality? A: We have rigorous quality test system, from raw materials to finished products, the materials must be checked and signed by QC people.