Description

| Building Facade Curtain Wall Perforated Aluminum Panel | |

| I. Introduction of Aluminum Sheet

Coating aluminum coil and plate, which is combined with the roller coating technology with digital printing technology. On one side or two sides of aluminum coil, make the pre-treatment of degreasing, cleaning, conversion film, using high-quality polyester or PVDF paints, passing many times coating and baking. |

|

| II. Details | |

| Alloy | 1000, 3000, 5000, 8000 series |

| Temper | H16, H26, H24, H22, H18 |

| Thickness | From 0.02mm to 3.0 mm |

| Width | From 25 – 1600 mm |

| Diameter | Standard dia:1100mm |

| Interior dia:150mm, 405mm, 505mm | |

| Weight | 2.0-3.0 Tons/coil |

| Coating | PVDF, PE, HDPE, PU, PVC or AC |

| Surface | Embossed, Mill finish, Coated |

| Color | RAL or Customized |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron |

| PVDF: more than 25 micron | |

| Coating Hardness (pencil resistance) |

More than 2h |

| Coating Adhesion | 5J(EN ISO-2409:1994) |

| Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility (T-bend) | ≤2T |

| MEK Resistance | More than 100 |

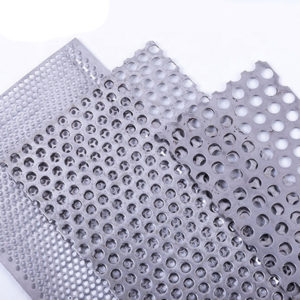

| III. Features A. Sunlight and radiation containment B. Heat dissipation C. Perfect filtration performance D. Anti-skid E. Protective function |

|

Punching Sheet Hole:

Rectangular hole , Square hole , Diamond hole , Hole , Hexagonal hole , Cross hole , Triangle hole , Long hole , Along waist hole , Plum blossom hole , Scale hole , Hole Pattern , Star shaped holes , Irregular holes ,Drum hole etc,

Surface Treatment Process:

Skim →Alkali-Corrosion → Blare-elimination(by acid) →Chromiumizing → Drying → Parts-installation →Spraying Solidifying → Parts- removing → QC& Packing

Fabrication Process:

Sheet Metal Cutting- CNC Cutting(Punching,Laser Cutting-Hollow out)- Bending- Welding-Bracket Fixing-Polishing-Surface Treatment- QC-Package

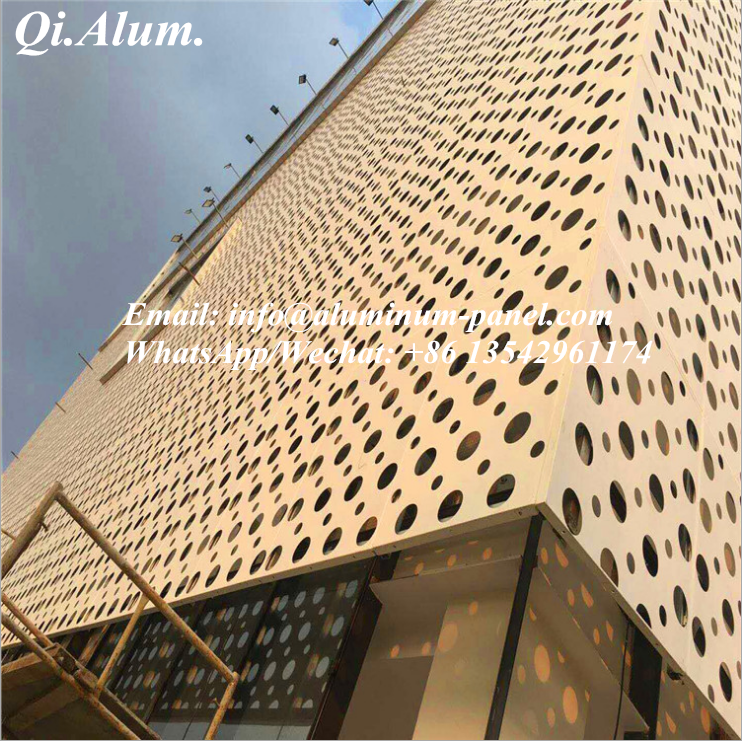

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence :

Decorative Living Room, Hotel, Bar, etc.

Indoor and outdoor public space backdrop, Elevator cabin, handrail,living room, background wall, ceiling, Kitchen equipment.

Specially for bar,club,KTV,hotel,bath center,villa,shopping mall

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

Projects list:

Why us

1. Support online transactions and provide $15000 financial security for customers

2. Special custom perforated products make your project unique

3. From the selection of materials to the surface treatment, one-stop production, quality control by ourselves, can better ensure the quality of customers request

4. Provide installation suggestions for your local team

5. Payment can be fastest received on the same day, greatly shortening the delivery time

FAQ

Q: How long can I get a quote?

A: The quotation can be provided no longer than 24 hours on condition that we know all detailed requirements.

Q: Can I get samples?

A: Free sample can be offered. Delivery can be arranged within 48 hours.

Q: Delivery time

A: 3~8 day workdays (in Stock); 10~25 day workdays (out of Stock).

Q. Why can I trust you and place an order with you?

A: From 2002 to 2018 is with 16 years’ experience in this industry, we have served clients

from more than 100 countries, Hengzhan is well-known for its quality and team, and wins clients’ trust by honesty and down to earth business style.

Q: Can you provide OEM service?

A: Yes. Color, size, protective film and coating can be we also can produce under your own brand name as long as logo and design be provided.

Q: What’re your company’s main products?

A: Color coated aluminum coil/strip/sheet/panel, aluminum ceiling, and curtain wall

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!