Description

Aluminum air conditioning cover has many significant characteristics and advantages.

First of all, light weight is one of its major characteristics. Compared with air conditioning covers of other materials, aluminum alloy material has a low density, making aluminum air conditioning covers more convenient in installation and handling, and will not bring excessive additional burden to buildings. At the same time, it has good pressure resistance and is durable. It can withstand a certain amount of external impact and is not easily damaged, providing reliable protection for air conditioning outdoor units.

In terms of process performance, aluminum air conditioning covers perform outstandingly. It can be freely processed into various complex geometric shapes to meet the individualized needs of different customers. Whether it is a flat surface, arc shape or spherical surface, etc., it can be easily achieved, providing more creative space for architectural design.

The optional color is also one of the advantages of aluminum air conditioning covers. Customers can customize air conditioning covers of any color according to their own preferences and architectural styles to achieve personalized decorative effects. Moreover, its surface treatment effects are rich. Effects such as stone texture and wood texture can be easily achieved, greatly enhancing the aesthetics of air conditioning covers.

The easy-to-clean characteristic makes aluminum air conditioning covers very worry-free in daily maintenance. Its surface is smooth and not easy to adhere to pollutants. The non-adhesive property of the fluorocarbon coating film makes it difficult for dust and other substances to adhere. Even if there are stains, they can be automatically cleaned by rain washing and even have self-cleaning function.

Convenient installation is another advantage of aluminum air conditioning covers. Installation issues are fully considered during production and customization. There is no need for cutting on the construction site. It only needs to be simply fixed. Installation can be easily completed without professional technicians.

In addition, aluminum air conditioning covers are environmentally friendly and recyclable. It is safe, harmless, without peculiar smell and formaldehyde, and meets environmental protection requirements. Moreover, aluminum plates can be 100% recycled, with higher recycling value, which is conducive to the recycling of resources.

II. Exquisite processing technology

(一) Shaping stage The sheet metal processing of aluminum air conditioning covers is divided into nine steps. First is cutting and setting out. Prepare aluminum plates by means of shearing and cutting. Then carry out corner punching and hole punching operations to lay the foundation for subsequent assembly and shaping. Then, form the aluminum plate by using processes such as bending and rolling to process the aluminum plate into the required shape. In the shaping step, inspection will be carried out to ensure that the shape meets the requirements. Subsequently, argon arc welding is carried out to firmly connect various parts. Assembling the reinforcing ribs includes making the reinforcing ribs to enhance the strength of the air conditioning cover. Then assemble the corner codes, which also includes making the corner codes. After that, perform grinding and polishing to make the surface smooth and flat. Finally, conduct inspection to ensure the quality of sheet metal processing.

(二) Pretreatment stage Aluminum air conditioning covers adopt German imported pretreatment process and reagents to ensure that the aluminum plate workpiece is passivated and filmed to improve paint adhesion. The pretreatment process flow has eight steps. First is the immersion treatment tank to fully soak the aluminum plate. Then carry out pickling, using a three-in-one method of acid, alkali, and surface conditioning to remove impurities on the surface of the aluminum plate. Then carry out water washing to remove residual acid, alkali and other substances. After two water washings, carry out passivation and film formation to form a protective film on the surface of the aluminum plate. After two more water washings to ensure a clean surface. Finally, carry out pre-drying to prepare for spraying.

(三) Spraying stage The spraying process and equipment for aluminum air conditioning covers use the American Nordson continuous automatic spraying and baking line. The spraying process flow has eleven steps. First is loading, placing the aluminum plate on the spraying line. Then spray primer with a dry film thickness of 5 – 8 microns. Then carry out leveling and maintain for 10 minutes under room temperature and clean environment conditions. Then spray topcoat with a dry film thickness of 20 – 25 microns. Also carry out leveling and maintain for 10 minutes. Then spray clear coat with a dry film thickness of 10 – 15 microns. Level again for 10 minutes. After that, carry out curing and drying, and dry for 20 minutes at 240 degrees Celsius plus or minus 10 degrees. Natural cooling reduces the surface temperature of the aluminum plate to room temperature. Finally, conduct inspection, including inspection of film thickness, color difference, surface quality and other aspects. Unload to complete the spraying process.

III. Wide range of application scenarios

(一) Building exterior wall decoration Aluminum air conditioning covers have a wide range of applications in building exterior wall decoration. In street renovation projects, it can add a modern and artistic atmosphere to old streets. For example, in some old street renovation projects in cities, aluminum alloy air conditioning outdoor unit covers are used to effectively cover and decorate the originally rusty air conditioning outdoor units, making the streets cleaner and more beautiful. As an important place for displaying images, hotels can enhance the grade and quality of hotels by using aluminum air conditioning covers. New commercial buildings are also increasingly choosing aluminum air conditioning covers to beautify the building appearance, making the entire community’s buildings more beautiful and enhancing the attractiveness of the buildings.

(二) Protecting air conditioning outdoor units Aluminum air conditioning covers play an important role in protecting air conditioning outdoor units. It can slow down the aging of air conditioners. Since air conditioning outdoor units are exposed outdoors all year round and are subjected to wind, sun, rain and rain, problems such as rust and oxidation of the shell are prone to occur. Aluminum air conditioning covers can effectively block these factors and extend the service life of air conditioners. At the same time, it can also prevent dust from accumulating on the filter screen, maintain the ventilation performance of air conditioners, and improve the working efficiency of air conditioners. During the typhoon and flood prevention period, aluminum air conditioning covers can also provide additional safety guarantees for air conditioning outdoor units and reduce the hidden danger of falling objects from high altitudes.

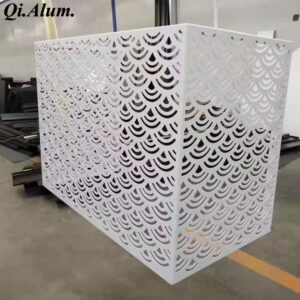

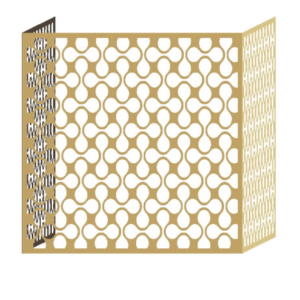

(三) Meeting individualized needs Aluminum air conditioning covers have a variety of different styles of metal-shaped hollowed-out styles, which can meet the diverse needs of customers. For example, some air conditioning covers adopt carving technology, which is exquisite and delicate, highlighting classical beauty; some adopt punching design, which is simple and generous, full of modernity. Customers can choose different styles and colors according to the overall style of the building and personal preferences. In some personalized villas, hotels and other places, aluminum air conditioning covers have become the highlight of decoration, adding unique charm to the building. According to statistics, there are currently many brands of aluminum air conditioning covers on the market, providing as many as hundreds of styles, which can meet various needs of different customers.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!