Many customers are asking what is the difference between hyperbolic aluminum plate and arc aluminum plate. They look very similar, and now I’m going to share with you the difference between hyperbolic aluminum and curved aluminum.

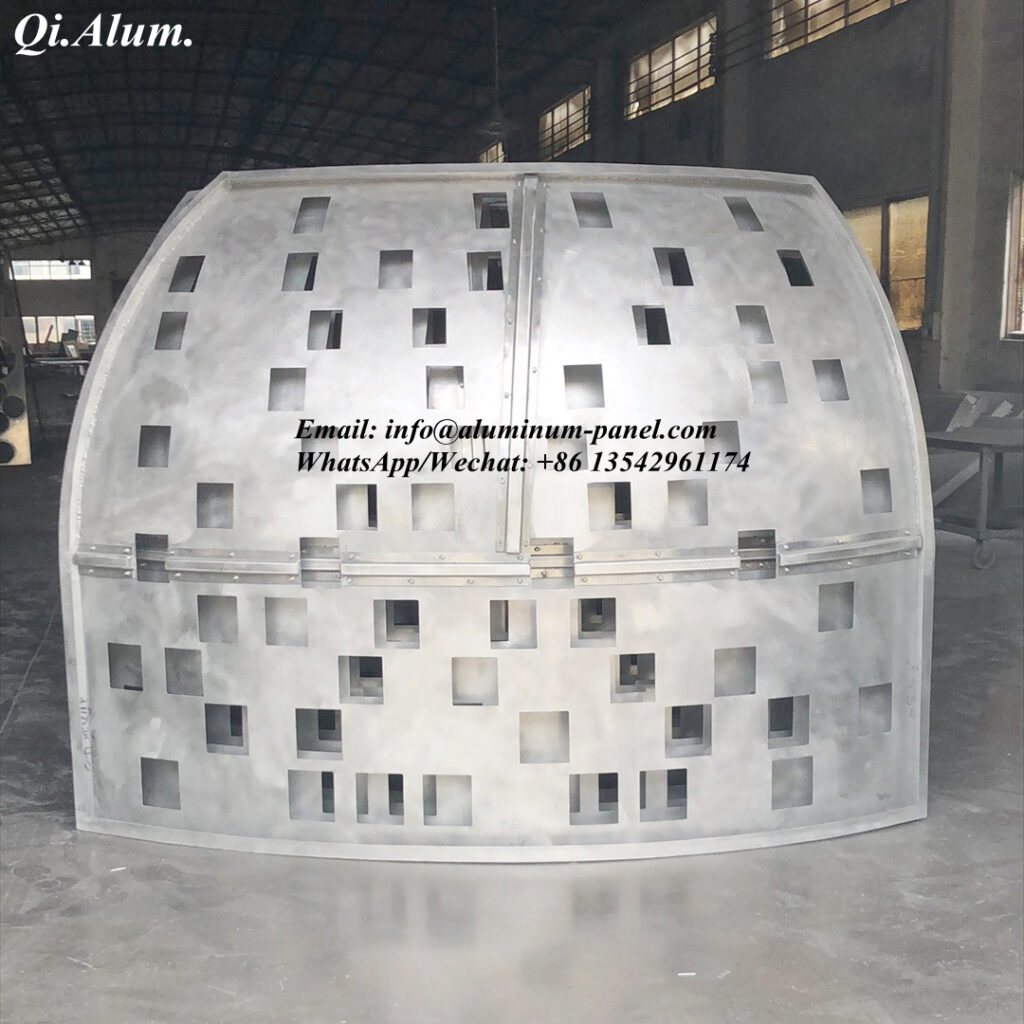

Hyperbolic aluminum plate, curvature is not straight meaning, the important feature is that there are more than two surfaces, such as spherical, ingot modeling, vase modeling are a plurality of surfaces composed of hyperbolic aluminum plate.

Second arc processing is also quite difficult, to carry out the decomposition of each surface calculation, cutting, and then to the welding. The welding difficulty of hyperbolic aluminum sheet is much higher than that of conventional aluminum sheet.

It is necessary to take into account the internal pressure, physical stretching and other problems, and then slowly splice into a whole.

Arc aluminum plate, arc is a shape of circle or ellipse, only one plane, one radian. Compared with hyperbolic processing simple, can be directly produced by machinery, do not need too much processing later.

Although hyperbolic aluminum sheet and arc aluminum plate have many differences in processing difficulty and surface structure, they are widely used in the exterior wall decoration of many large projects.

Double curved aluminum plate with its unique shape, for designers and owners to provide a wider imagination and design space.

After such a comparison, I believe we have a new understanding of the hyperbolic aluminum sheet and arc aluminum plate.

Hyperbolic aluminum sheet raw materials with high plastic strain ratio can produce large compression deformation, which is beneficial to wrinkle prevention; The material with large hardening index and elongation can reduce the local thinning and increase the degree of deformation, which is beneficial to prevent cracking. The first design of hyperbolic aluminum plate processing is the forming mold.

Under the action of the mold, forcing the thickness of the blank to reduce and increase the surface area, to obtain the geometric shape of the parts of the processing method, known as bulging. Many complex plates can be machined by these processes. It is mainly used for partial forming of slab blank, integral forming and diameter expanding of cylindrical hollow blank.

According to forming area classification: local bulging, integral bulging and large surface bulging. According to forming die classification: rigid die bulging, solid soft die bulging and liquid (gas) pressure bulging.