Description

Here are some methods to improve the corrosion resistance of aluminum air conditioning covers:

- Anodizing treatment

- Principle: Anodizing is an electrolytic oxidation process. The aluminum air conditioning cover is used as the anode. Through electrolysis in the electrolyte, a dense oxide film is generated on its surface. This oxide film has strong corrosion resistance because it can prevent corrosive media from the outside (such as oxygen, moisture, acidic or alkaline substances, etc.) from directly contacting the aluminum substrate.

- Operation process: Usually, the aluminum air conditioning cover is placed in a solution containing electrolytes such as sulfuric acid and oxalic acid. A certain voltage and current are applied. After a period of time, an oxide film is formed on the aluminum surface. For example, in sulfuric acid electrolyte, by controlling the appropriate current density (such as 1 – 2A/dm²), temperature (18 – 22℃), and oxidation time (20 – 30 minutes), an oxide film with appropriate thickness and good quality can be obtained.

- Chemical conversion film treatment

- Principle: Use chemical solutions to react with the aluminum surface to generate an amorphous conversion film. This conversion film can provide a good substrate for subsequent coatings and also has certain corrosion resistance. For example, chromate conversion film treatment is a relatively common method. Chromates form a chromium-containing compound film on the aluminum surface. The chromium element in it can play a passivating role and prevent further corrosion.

- Operation process: Immerse the aluminum air conditioning cover in a solution containing chemical agents such as chromates and phosphates. Taking chromate conversion film treatment as an example, the concentration of chromates in the solution is generally 3 – 5g/L, the treatment temperature is 30 – 40℃, and the treatment time is about 5 – 10 minutes. After treatment, it needs to be thoroughly washed to remove residual chemical agents on the surface.

- Powder coating treatment

- Principle: Spray powder coatings evenly on the surface of the aluminum air conditioning cover, and then melt, level and cure it by heating to form a continuous protective film. Powder coatings can choose materials with good corrosion resistance such as polyester and polyurethane. This protective film can isolate aluminum from the external environment and prevent corrosive substances from eroding aluminum.

- Operation process: First, pretreat the surface of the aluminum air conditioning cover, such as degreasing and rust removal, to ensure the surface is clean. Then use an electrostatic spray gun to spray the powder coating evenly on the surface. The coating thickness is generally 60 – 120μm. Then put it into a curing oven and cure it at a temperature of 180 – 200℃ for 10 – 15 minutes to fully cure the powder coating and form a firm protective film.

- Adding alloying elements

- Principle: Adding an appropriate amount of alloying elements such as magnesium, zinc, and manganese to aluminum can change the microstructure of aluminum and improve its corrosion resistance. For example, in aluminum-magnesium alloys, magnesium elements can form a stable compound and form a protective film on the aluminum surface to prevent corrosion. When the magnesium content is about 3 – 5%, the corrosion resistance of the alloy will be significantly improved.

- Application: In the production process of aluminum air conditioning covers, alloying elements are added to the molten aluminum by smelting. Then alloy plates are made through processes such as casting and rolling and used to manufacture air conditioning covers.

- Use of sealing strips

- Principle: Installing sealing strips at the gaps of aluminum air conditioning covers can prevent corrosive media such as moisture and dust from entering the cover body. Sealing strips are generally made of materials such as rubber or silicone, which have good elasticity and sealing performance.

- Operation: When installing the aluminum air conditioning cover, embed the sealing strip into the gap to ensure that the strip is closely attached to the cover body. For example, for air conditioning covers with splicing structures, install sealing strips at the splicing points. The width of the strips can be selected according to the size of the gap, generally about 3 – 5mm. This can effectively prevent the invasion of corrosive substances from the outside.

- Application of sealing paint

- Principle: Applying sealing paint on some tiny pores or possible leakage points on the surface of the aluminum air conditioning cover can further improve its sealing performance. Sealing paint can fill tiny defects on the surface and form a continuous protective layer.

- Operation: After the aluminum air conditioning cover undergoes surface treatment, use a brush or spray gun to evenly apply the sealing paint on the surface, especially at parts prone to corrosion such as corners and interfaces. The thickness of the sealing paint is generally about 10 – 20μm, and make sure to use the air conditioning cover after it is completely dried and cured.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

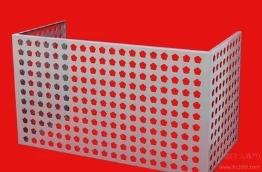

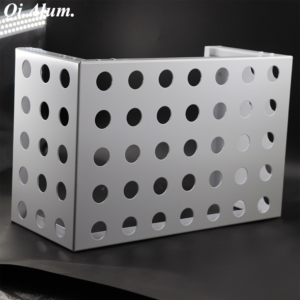

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!