Aluminum perforated sheet is a sheet of metal, usually aluminum, that has been mechanically punched with a pattern of holes. The holes can vary in size, shape, and number, and can be used for a variety of purposes, such as decorative accents, ventilation, and soundproofing.

Advantages of Aluminum Perforated Sheet:

1. Lightweight – Aluminum is much lighter than other metals, making it ideal for use in applications where weight is a factor.

2. Corrosion Resistant – Aluminum is naturally resistant to corrosion and can withstand harsh environments.

3. Durable – Aluminum has a high strength-to-weight ratio and is highly resistant to wear and tear.

4. Heat Resistant – Aluminum can withstand high temperatures and is often used in applications such as automotive exhaust systems.

5. Low Maintenance – Aluminum is low maintenance, requiring little to no upkeep in many applications.

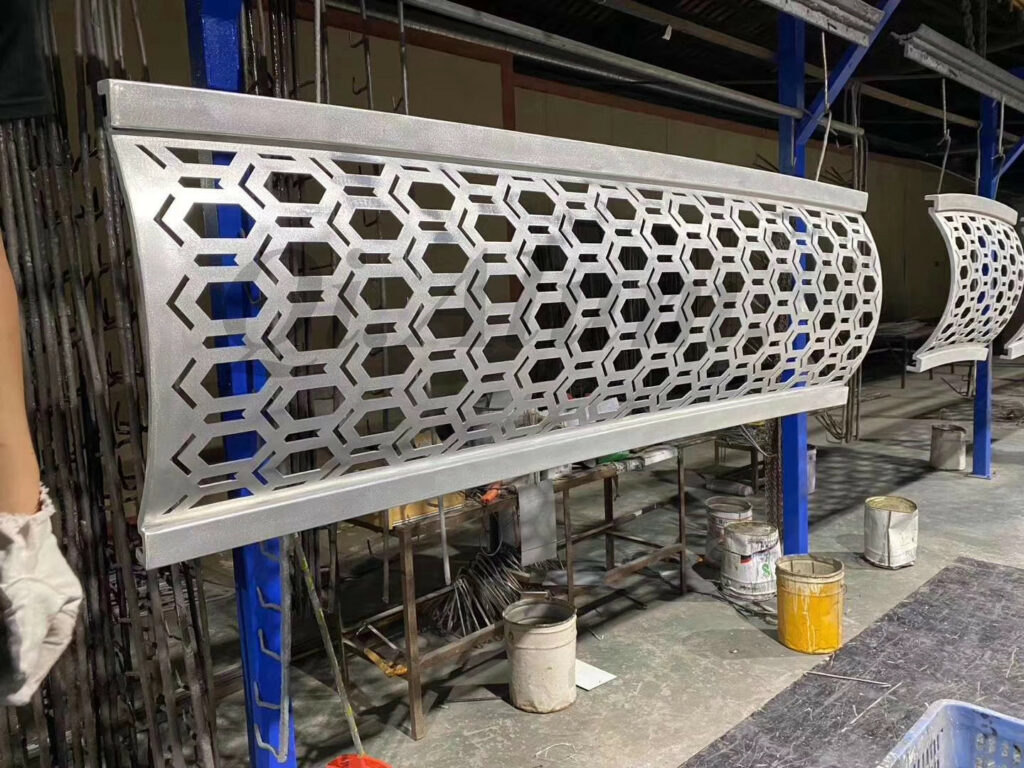

6. Aesthetically Pleasing – Aluminum has a shiny and attractive finish, making it perfect for use in many decorative applications.

7. Versatile – Aluminum can be formed and shaped into a variety of shapes and sizes, making it ideal for a variety of applications.

8. Eco-Friendly – Aluminum is a recyclable material, making it an environmentally friendly choice.

9. Cost-Effective – Aluminum is relatively inexpensive compared to other metals, making it a cost-effective choice.

10. Easy to Install – Aluminum is easy to install, making it a great choice for many projects.

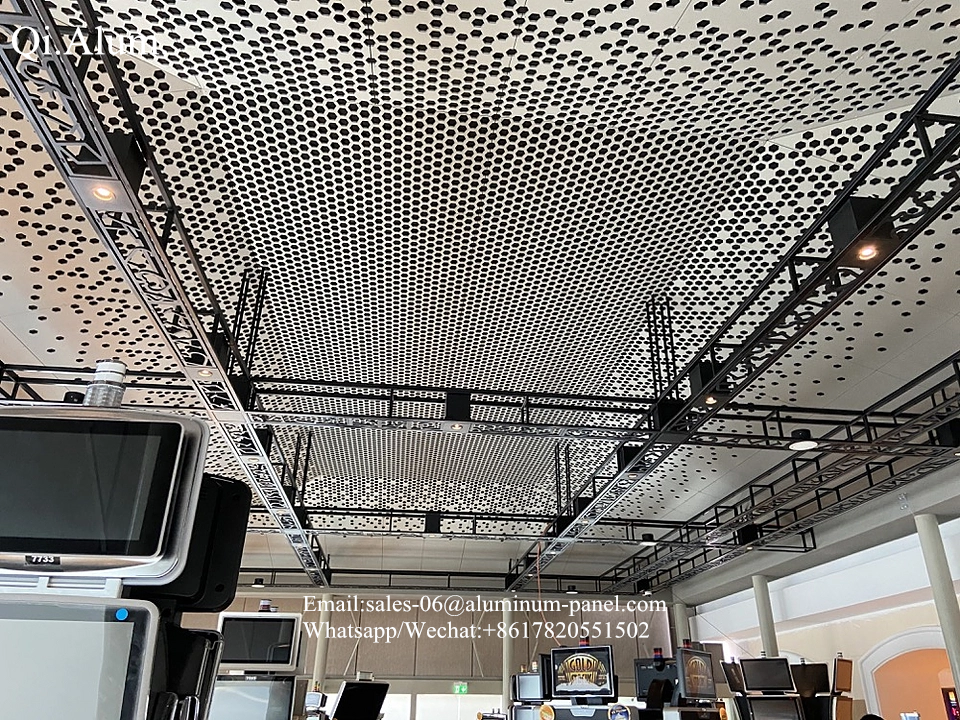

Aluminum perforated sheet can be used in a variety of applications, such as ceiling tiles, wall decorations, signage, furniture, screens, and filters. It is also commonly used to create privacy screens, soundproofing, and ventilation systems.

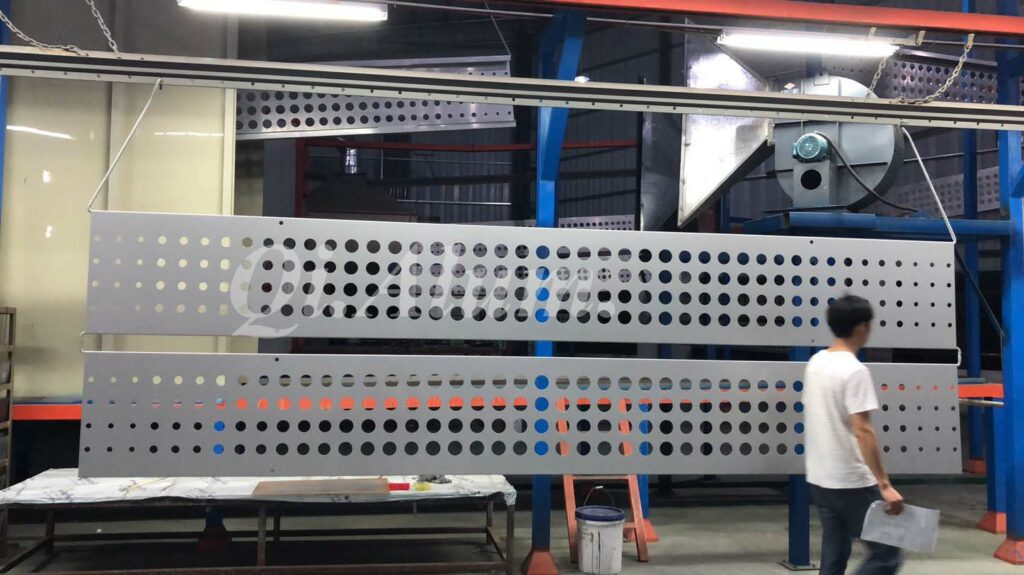

The surface treatment of aluminum perforated sheet can vary depending on the application. Common treatments include anodizing, painting, powder coating, and galvanizing.

The dimensions of aluminum perforated sheet can vary depending on the application. Common sizes include 3/64”, 1/16”, 3/32”, 1/8”, 3/16”, 1/4”, 5/16”, 3/8