Description

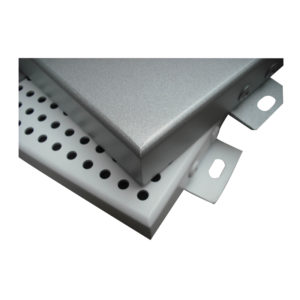

Features: 1. Light weight;

The density of aluminum is 2.73 g/m3, only 1/32 of the steel, high strength;

Through components configuration, process and heat treatment method can achieve very high intensity.

3. Corrosion resistance;

Formation of oxide layer, can prevent the oxidation of the metal corrosion, good acid and alkali.

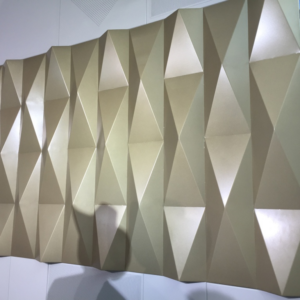

4. The surface treatment of diversity, and beautiful.

For anodic oxidation, chemical treatment, polishing, painting treatment 5. Plasticity is good, easy treatment 6. Good electrical conductivity.

Preventing electromagnetic interference and can reduce the flammability of under special circumstances.

7. Easy installation;

Aluminum metal can connect riveting, welding, adhesive and so on a variety of ways.

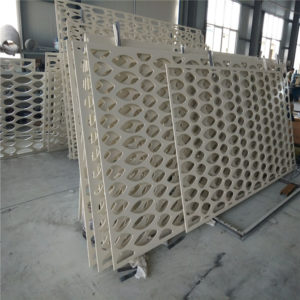

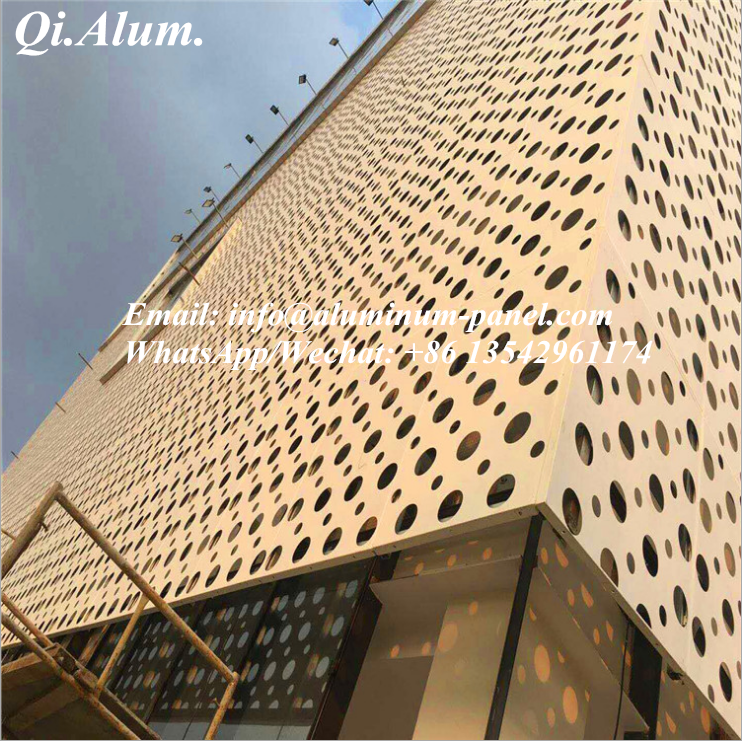

Hollow aluminum panel production process there are three main steps: the first is the strength of high quality aluminum alloy plate after cutting shear, arc line open Angle, bending, rolling, argon arc welding, grinding, assembly, polishing processing.

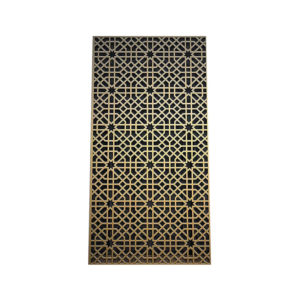

The second is the preliminary processing of aluminum panel by chromizing process, using large-scale laser engraving machine to hollow out processing, including hollow out design decorative pattern, etc can be customized according to customer’s individual requirements.

The third is the use of fluorine carbon spraying technology to form a layer on the surface of aluminum panel fluorocarbon film.

Fluorocarbon coatings are mainly poly (vinylidene fluoride resin, its main divided into primer, paint, varnish 3 kinds.

Spraying process is generally divided into two baked three and four three baked.

Three of the varnish for face spray primer paint (protective lacquer), four face isolation for spray primer paint paint varnish (paint).

Punching Sheet Hole:

Rectangular hole , Square hole , Diamond hole , Hole , Hexagonal hole , Cross hole , Triangle hole , Long hole , Along waist hole , Plum blossom hole , Scale hole , Hole Pattern , Star shaped holes , Irregular holes ,Drum hole etc,

Surface Treatment Process:

Skim →Alkali-Corrosion → Blare-elimination(by acid) →Chromiumizing → Drying → Parts-installation →Spraying Solidifying → Parts- removing → QC& Packing

Fabrication Process:

Sheet Metal Cutting- CNC Cutting(Punching,Laser Cutting-Hollow out)- Bending- Welding-Bracket Fixing-Polishing-Surface Treatment- QC-Package

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence :

Decorative Living Room, Hotel, Bar, etc.

Indoor and outdoor public space backdrop, Elevator cabin, handrail,living room, background wall, ceiling, Kitchen equipment.

Specially for bar,club,KTV,hotel,bath center,villa,shopping mall

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

Projects list:

FAQs

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 40% as deposit, and 60% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 15-25 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!