Description

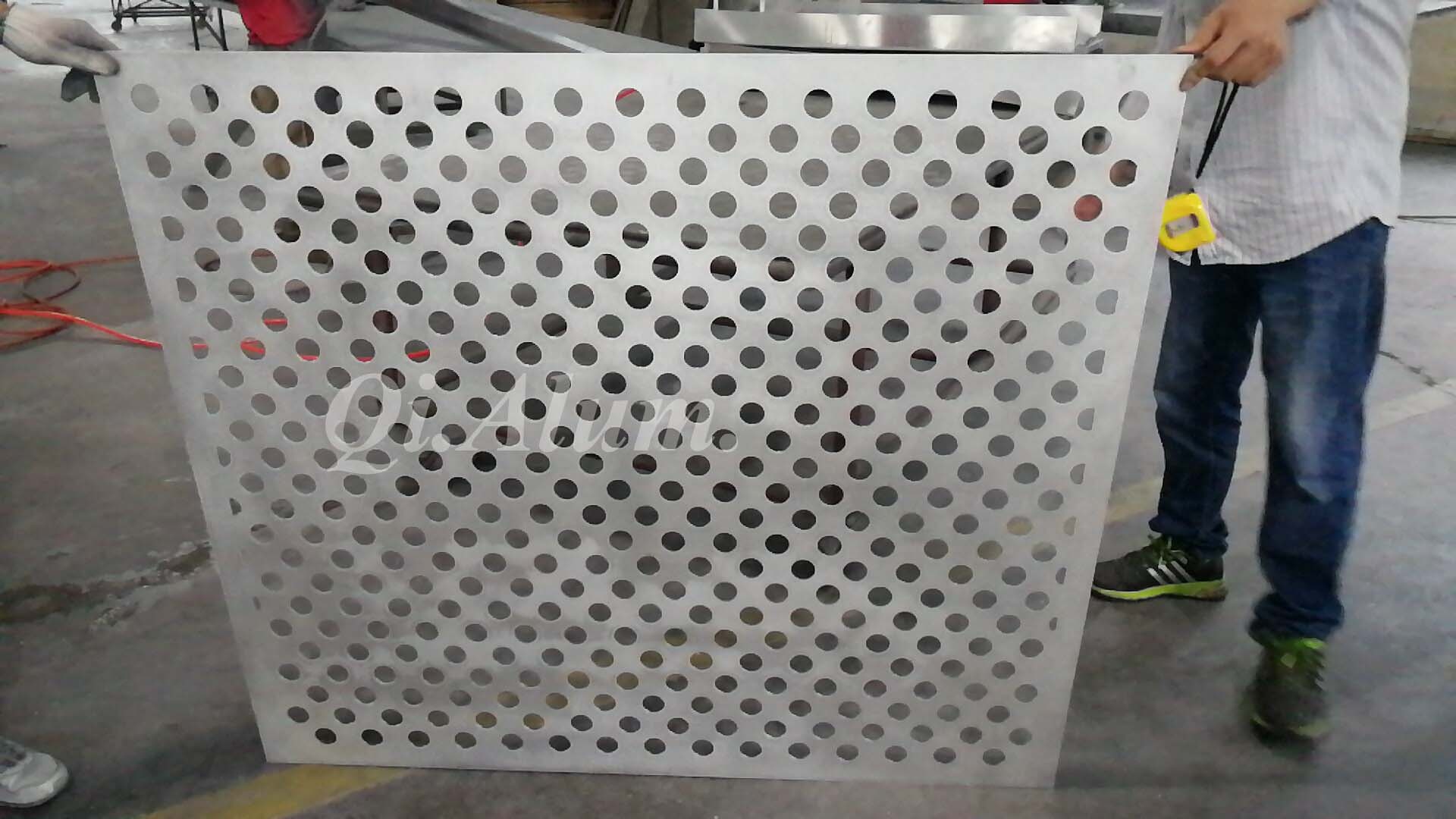

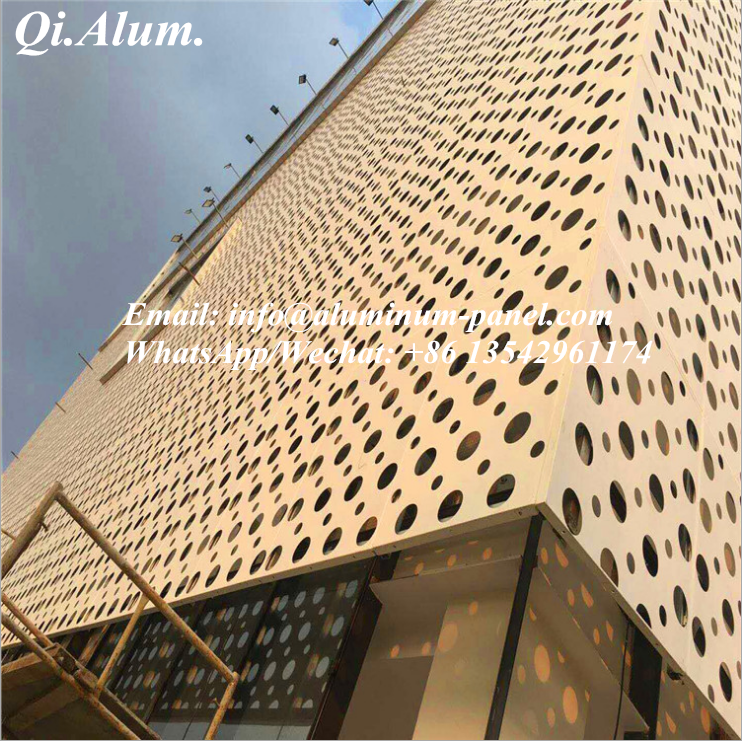

Round Holes Fireproof Aluminum Wall Cladding Metal Sheet for Building Decorative

| Item | Description |

| Material | AA1100,AA1050,AA1060,AA3003,AA5005,AA6063 |

| Thickness | 1 mm to 10 mm |

| Recommend size | 1500mm*4000mm other size are available |

| USAGE | facade, decorative panel, curtain wall |

| Surface Treatment | Powder coating, PVDF, woodengrain color |

| Color | Any RAL colors or Pantone color chart for your choice |

| Pattern (design) | According to architectural design

|

Application

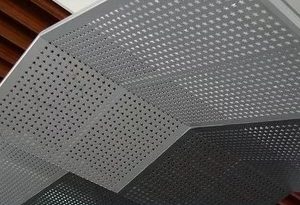

♦ Interior and exterior wall cladding for commercial or residential buildings

♦ Waterproof sheets for bathroom, kitchen, ceiling

♦ Decoration material for shops, hotel, subway

♦ Building construction materials, material for vehical, boats and traffic signage boards

♦ Decorative panel for cabinets, gondola, wardrobe

♦ Both one-side color panel and double-side color panel can be made

Feature of perforated metal:

- Easily process. There are a variety selection of plate thickness, pore size and arrangement.

- Beautiful appearance, our products through painting or polishing have the advantage of abrasion resistance and long service life.

- Uniform mesh and smooth surface.

- Low cost, easy to install.

Making Process

- First cut the (pre galvanized) iron tube(round or square) into the required length.

2. Use the mould to fix the cut tube then weld the rail and pickets. there are two welding methods :

A. full welding B.point welding

The workers first use the small polish machine to polish the welding points one by one .

3. After finished all the welding ,using the big polish machine (steel sand ) to wash the oil .

4. Then make the whole fence to do the chromium plated .

5. Fianlly to do the powder coating .

FAQs

Q1: What is delivery time?

A: 15 days after deposit. Except for public holidays.

Q2: How can you guarantee the quality?

A: We have rigorous quality test system, from raw materials to finished products, the materials must be checked and signed by QC people.

Q3: How can I see more cases or information for this product?

A: Please contact us via whatsapp/wechat…..

Q4. Can you make custom panels if I have a design in mind?

A4: Yes, most of our products for exporting were manufacture to specs.

Q5. Do you offer a warranty on your products?

A5: Yes, for PVDF coating product we can provide more than 20years warranty time

Production of sheet metal:

Sheet metal spraying:

Product packaging:

Packing Details:

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request.

3. Excellent in weather fastness and corrosion resistance.

4. Good fireproof and waterproof property.

5. Even coating, various colors.

6.Easy to process ,easy to maintain.

The container shipping:

Punching Sheet Hole:

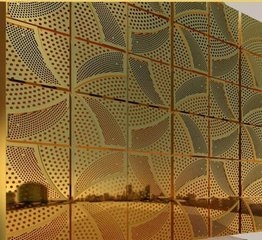

Rectangular hole , Square hole , Diamond hole , Hole , Hexagonal hole , Cross hole , Triangle hole , Long hole , Along waist hole , Plum blossom hole , Scale hole , Hole Pattern , Star shaped holes , Irregular holes ,Drum hole etc,

Surface Treatment Process:

Skim →Alkali-Corrosion → Blare-elimination(by acid) →Chromiumizing → Drying → Parts-installation →Spraying Solidifying → Parts- removing → QC& Packing

Fabrication Process:

Sheet Metal Cutting- CNC Cutting(Punching,Laser Cutting-Hollow out)- Bending- Welding-Bracket Fixing-Polishing-Surface Treatment- QC-Package

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence :

Decorative Living Room, Hotel, Bar, etc.

Indoor and outdoor public space backdrop, Elevator cabin, handrail,living room, background wall, ceiling, Kitchen equipment.

Specially for bar,club,KTV,hotel,bath center,villa,shopping mall

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence:

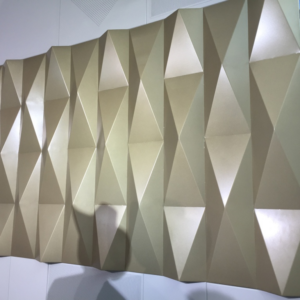

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

Projects list:

Q1: What is delivery time? A: 4 weeks days after deposit. Except for public holidays.

Q2: How can you guarantee the quality? A: We have rigorous quality test system, from raw materials to finished products, the materials must be checked and signed by QC people.

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!