Description

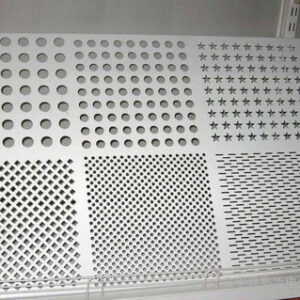

Perforated Aluminum Sheet with Various Holes Shape/Decorative Mesh Sheet/Stainless Steel Perforated Metal Mesh

perforated metal mesh

Thickness: 0.3-5mm

Hole: 0.6-20mm

Material: Low carbon steel, aluminum, stainless steel

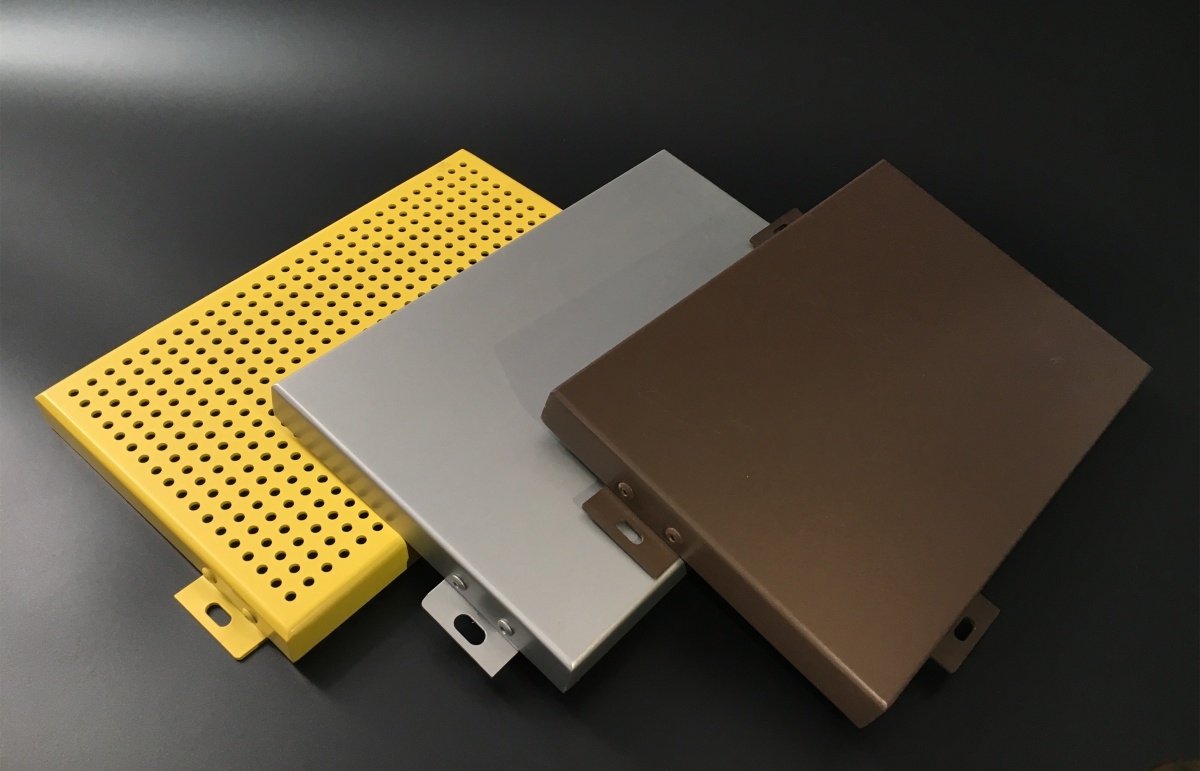

| Material | aluminium plate, stainless steel plate, copper plate, etc. |

| Color | golden, silver, red, black, white, etc. |

| Surface treatment | galvanized, powder coated, etc. |

| Feature | corrosion resistance, customized hole shapes, easy installment, etc. |

| Application | decoration, construction, etc. |

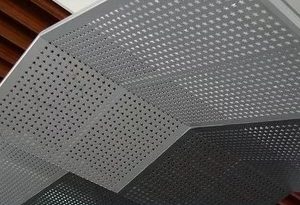

Application

used in roofing, interior panels, engineering square tube, curtain wall, composite panel

used in stretched plate, ceiling, curtain wall, square tube, engineering slab, shutter door, door cabinet, embossing, gutter, advertising board

used in ACP, engineering interior panel, curtain wall, aircraft fuel tank

used in radiator, bottle cap, ACP, square tube, embossing, aluminum foil

Our service

1. From raw materials to process treatment, we cooperate with well-known brands with stable quality and reputation of the industry.

2. Adopting the German technology, through the three-times coating and baking, 12 testing procedures to ensure that no paint shedding, bumps, coating voids.

3. The advanced colorimeter and error-detecting facility on thickness make sure ensure the quality.

4. the introduction of 8 advanced production lines from Germany, including four color layer lines, two cutting lines, two embossing lines, and a new production line of protective film.

5. Full sets quality inspection: include the control of raw materials, the measurement of thickness and color difference during production, as well as the measurement of thickness and bending of products before packing.

FAQs

Q: How long can i get a quote?

A: The quotation can be provided no longer than 24 hours on condition that we know all detailed requirements.

Q: What is the payment term?

.A: T/T or L/C.

Q: Do you offer sample?

A: Free sample can be offered. Delivery can be arranged within 48 hours.

Q: Where have you sold your products?

A: Nigeria, Africa, Middle East, Thailand, etc.

Q: Can i buy installation accessories from you?

A: Yes, we provide wet wall and dry wall system installation accessories.