Description

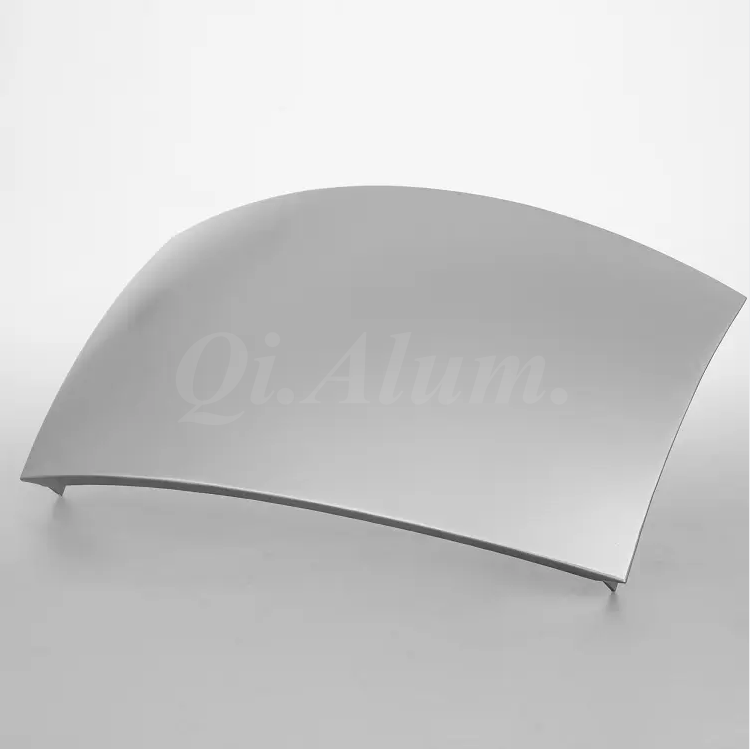

The segmented forming technology for aluminum double curved single panel processing: optimizing the forming model of the transition zone, forming large deformation and large-sized parts, achieving the formation of large workpieces with small equipment, and miniaturizing the dieless forming equipment. The application of this technology has produced samples that exceed seven times the area of the equipment workbench, with a total twist angle of over 40G on the twisted surface. Through this technology, the price of aluminum double curved single panel has been reduced to an acceptable range, making outstanding contributions to reducing the construction cost of modern hyperbolic buildings.

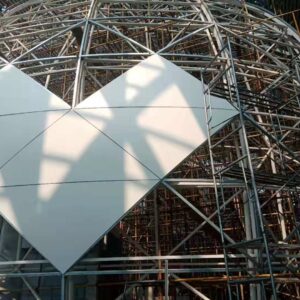

Large 3D aluminum double curved single panel products of different shapes and sizes can be found everywhere on ships, warships, aircraft, machinery, land vehicles, large containers, sculptures, and civilian products. In recent years, with the development of industries such as aviation, maritime transportation, high-speed railway, chemical industry, and urban construction, the demand for them has also been continuously increasing. However, outdated metal bending methods can no longer meet this development requirement, and the manufacturing technology urgently needed for aluminum double curved single panel processing.

The dieless multi-point forming technology has matured and can be directly used in actual production. It is particularly suitable for the multi variety and small batch production of curved panel products and the trial production of new products. The larger the size of the processed parts, the more outstanding their performance. Mouldless multi-point forming technology will have a broad application prospect in the processing of 3D curved panel products, such as the outer plate of ships and warships, the skin of aircraft and appliances, vehicles, large containers and the covering parts of urban sculpture, and will produce huge economic and social benefits.

Q: Are you a factory or a trade company?

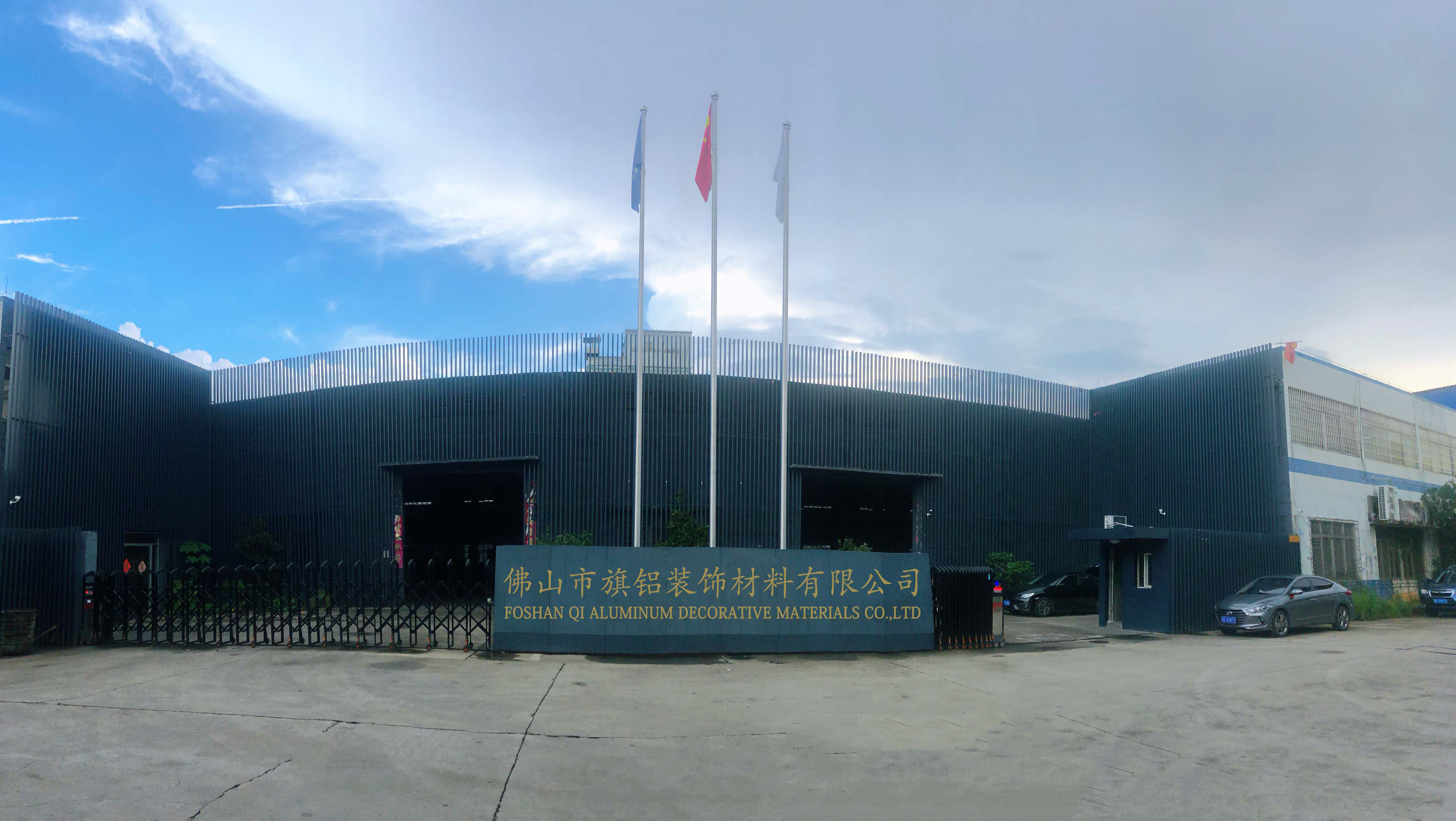

About us

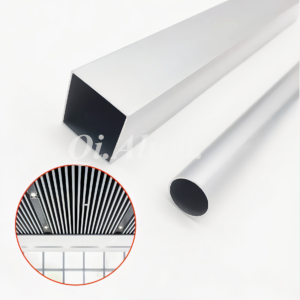

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!