Description

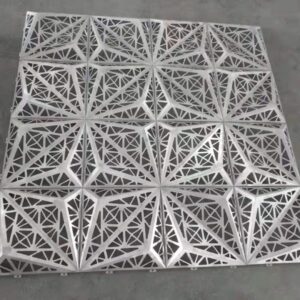

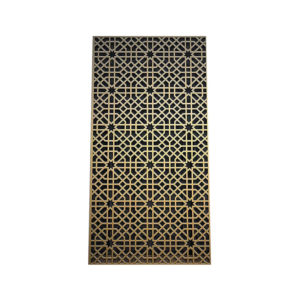

Building Facade Curtain Wall Perforated Aluminum Panel

| Building Facade Curtain Wall Perforated Aluminum Panel | |

| I. Introduction of Aluminum Sheet

Coating aluminum coil and plate, which is combined with the roller coating technology with digital printing technology. On one side or two sides of aluminum coil, make the pre-treatment of degreasing, cleaning, conversion film, using high-quality polyester or PVDF paints, passing many times coating and baking. |

|

| II. Details | |

| Alloy | 1000, 3000, 5000, 8000 series |

| Temper | H16, H26, H24, H22, H18 |

| Thickness | From 0.02mm to 3.0 mm |

| Width | From 25 – 1600 mm |

| Diameter | Standard dia:1100mm |

| Interior dia:150mm, 405mm, 505mm | |

| Weight | 2.0-3.0 Tons/coil |

| Coating | PVDF, PE, HDPE, PU, PVC or AC |

| Surface | Embossed, Mill finish, Coated |

| Color | RAL or Customized |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron |

| PVDF: more than 25 micron | |

| Coating Hardness (pencil resistance) |

More than 2h |

| Coating Adhesion | 5J(EN ISO-2409:1994) |

| Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility (T-bend) | ≤2T |

| MEK Resistance | More than 100 |

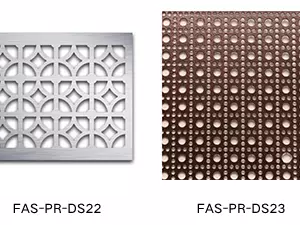

| III. Features A. Sunlight and radiation containment B. Heat dissipation C. Perfect filtration performance D. Anti-skid E. Protective function |

|

Why choose us

1. Support online transactions and provide $15000 financial security for customers

2. Special custom perforated products make your project unique

3. From the selection of materials to the surface treatment, one-stop production, quality control by ourselves, can better ensure the quality of customers request

4. Provide installation suggestions for your local team

5. Payment can be fastest received on the same day, greatly shortening the delivery time