Description

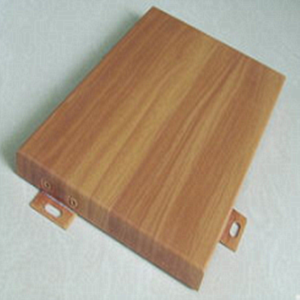

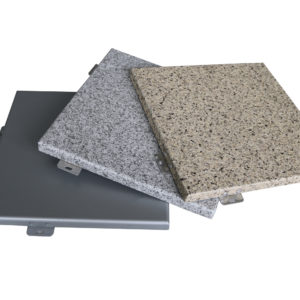

Anodized aluminum oxide refers to all aluminum or aluminum alloys that have been treated by an anodizing process. In principle, first of all, aluminum is active in nature, and when it comes into contact with air, a dense oxide film will immediately form on the surface. At the same time, it can also mold new properties by mixing different proportions of metal. The anodizing process is designed to prevent aluminum products from rusting or being corroded. From a technological perspective, it is mainly through the oxidation reaction treatment of anodized aluminum to ultimately form a relatively stable oxide film on the surface of aluminum products to isolate external chemical attacks.

Of course, this film is very thin and has a thickness of nanometers. In short, the anodic oxidation process is a membrane method that can maintain the appearance of equipment as new and extend its service life.

For example, the sanitary ware and bathroom rack in our daily life are mainly made of magnesium aluminum alloy, commonly known as “space aluminum”.

For example, mobile phone brands such as Apple and Huawei also use this material. Of course, such easy-to-use materials are indispensable in the construction materials industry, and even have become an “outstanding representative” of them. For example, anodized aluminum foil. It is widely used in building facade decoration, interior ceiling decoration, and so on.

With the opening of the 5G era, the advent of the intelligent era, and the ever-expanding demand for personalized decoration, more and more brands are beginning to introduce new materials, design concepts, and so on to meet the needs of consumers.

Facing the current situation that traditional materials can no longer meet the needs of the home decoration market, only by constantly breaking the boundaries can innovation be able to create a boundless and self breaking.

Anodized aluminum oxide is just a step forward in material innovation, and more new materials will enter people’s homes in the future.

FAQ

Q: Are you a factory or a trade company?

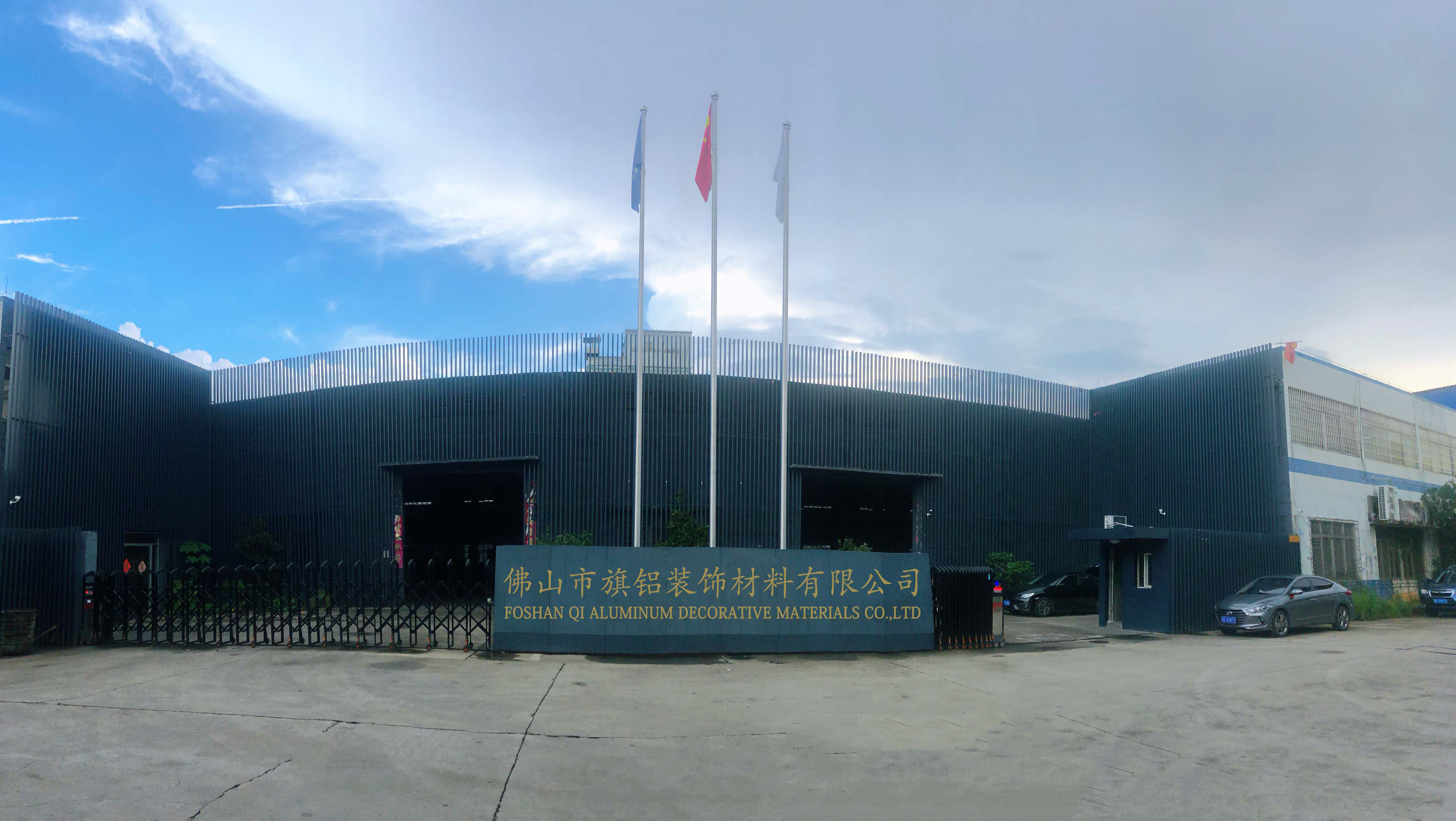

About us

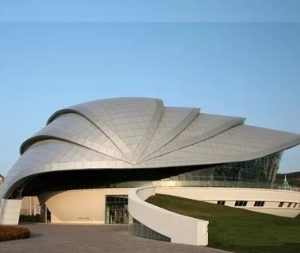

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!