Description

|

Product Name

|

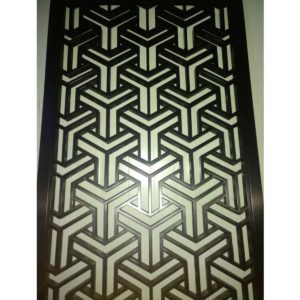

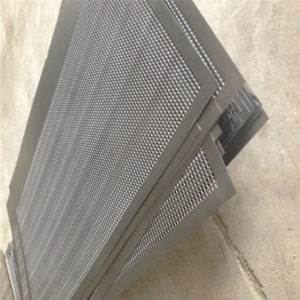

Aluminum Wall Cladding Panels Outdoor Perforated Metal Screen

|

|

Material

|

Aluminum with powder coated and corten steel

|

|

Color

|

according to customer’s design

|

|

Process

|

CNC Laser Cutting >Metal Bending > Welding and Polishing >Surface Treatment > Assembled Components and packaging.

|

|

Application

|

Outdoor decoration

|

|

Packing

|

Standard seaworthy packing or according to customer’s request

|

|

Trade Terms

|

EXW, FOB, CIF, C&F, etc

|

Whether your projects call for flat, bent, curved, compound shapes, painted stainless, caulked or dry joint materials, we have an aluminum panel system or combination of systems to meet your individual project needs. we help you reflect the future of design today while their materials retain tensile strength of heavy gauge sheet metal and are produced in the most sophisticated composite panel manufacturing facility in China.

We believe in the cladding industry and our professional design. We firmly stand by 100% of our work.

Aluminum Wall Cladding Panels Outdoor Perforated Metal Screen.Welcome inquiry!

Quality Control:

Each product has to meet a stringent supply specification which is outlined in the production documentation. To provide a product which consistently meets the specification requires a team effort and a system of monitoring critical checkpoints throughout the process.

The following are the critical checkpoints which are monitored and recorded:

Cladding specific job sheets clearly highlighting requirements

Barcode of all material to ensure supply and continuity from previous deliveries

Temperature control of each coil at time of machining.

Dimensional accuracy (width, cover, fit) and visual panel finish.

Visual panel finish and cover are checked throughout the batch.

The packer is the last person to see each piece. He pulls out anything that looks unacceptable.

Dispatch checks the presentation of each pack and completes the QA checklist on the production sheet. (number of packs, length etc.)