Description

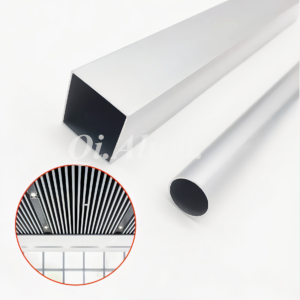

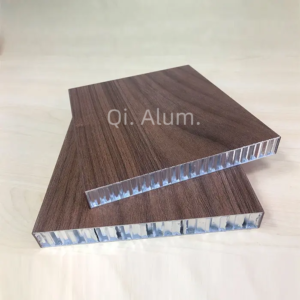

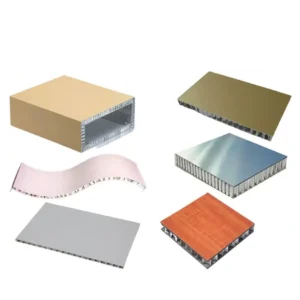

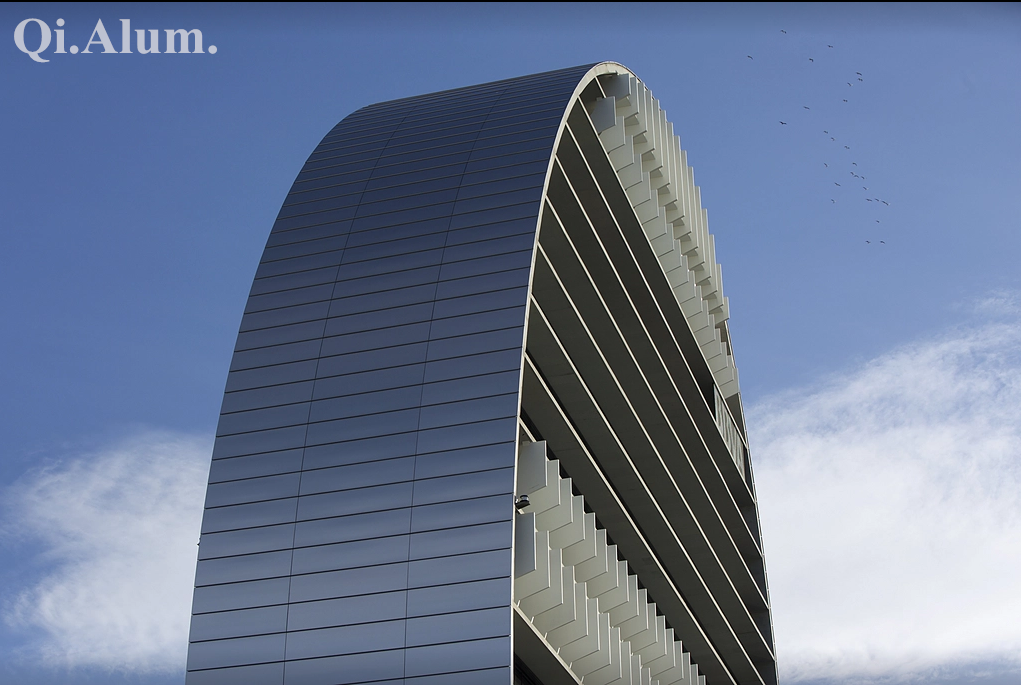

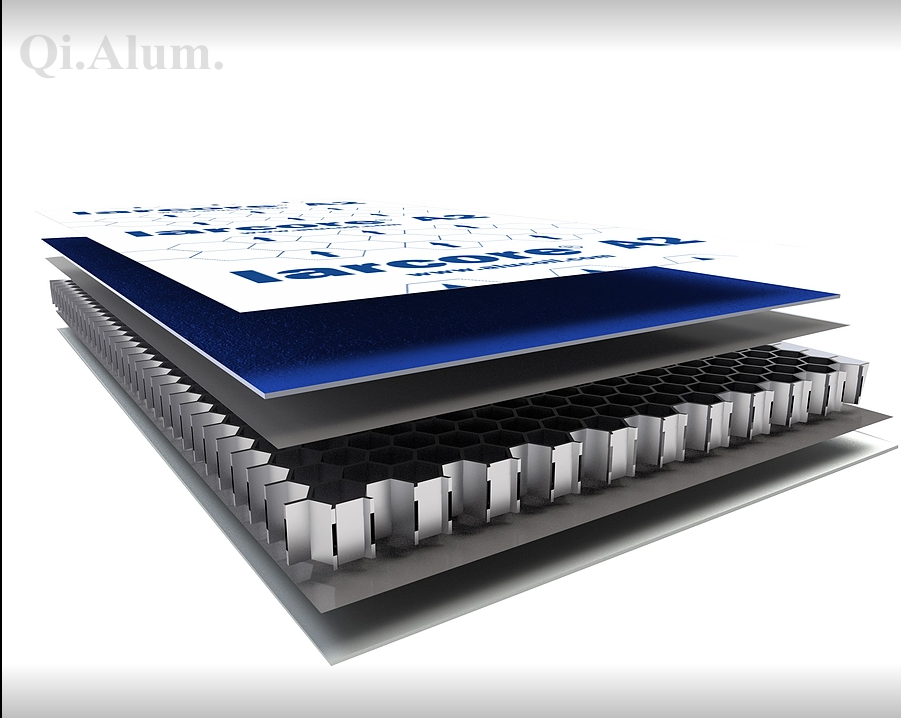

Modern architectural decoration generally requires panels to have thermal insulation and fire protection effects, especially for indoor wall decoration. The requirements for this aspect are stricter. In this trend of decoration, aluminum honeycomb panels are gradually receiving people’s attention. The structure of aluminum honeycomb panels is composed of a combination of panel surface, aluminum honeycomb core, and bottom plate, and the main structure is made of aluminum alloy material, which has good flame retardant effect. The combination of these three parts is like a biscuit, The honeycomb core is sandwiched in the middle to evenly distribute the force on the entire board, thereby improving the flatness of the aluminum honeycomb board. Compared to the aluminum single board, the hardness and flatness of the aluminum honeycomb board are the same, making it more aesthetically pleasing and tidy to install. The aluminum panel, honeycomb core, and bottom plate are bonded with special high-temperature resistant adhesive, which is firm and does not fall off.

Aluminum honeycomb panels can be divided into home decoration ceiling and engineering honeycomb panels. Generally, office buildings and office decorations can use 7mm thick aluminum honeycomb panels for decoration. The conventional ones include white, marble, and wood grain patterns, which are more choices than traditional white aluminum gusset panels. Engineering honeycomb panels are generally used for indoor wall decoration, with a thickness between 10mm and 50mm. Different thicknesses can meet the decoration needs of different places, The processing process of aluminum honeycomb panel is relatively long. Generally, engineering aluminum honeycomb panel needs to go through material cutting, cutting, bending, and then automatic glue spraying machine. After applying glue, the aluminum honeycomb core is pasted, and the aluminum panel is added on the back of the panel. After everything is ready, mount the hydraulic press. Generally, it takes 6 hours to press the aluminum honeycomb panel for engineering decoration, so that the panel and adhesive can be bonded for sufficient time and the flatness of the panel is also ensured.

Q: Are you a factory or a trade company?

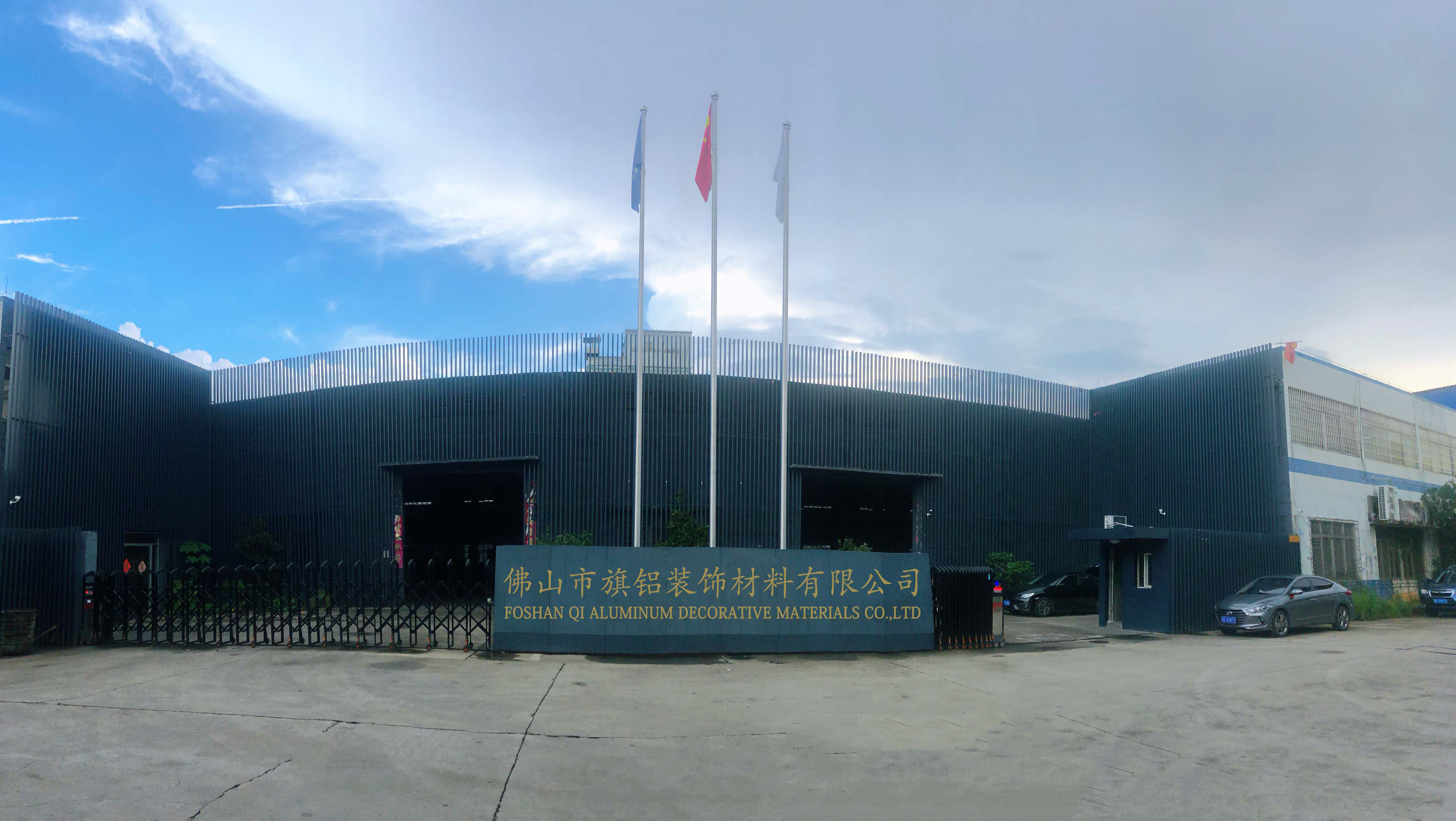

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!