Description

Aluminum Shadow Box Systems: The Future of High-Performance Building Envelopes with Aluminum Rock Wool Technology

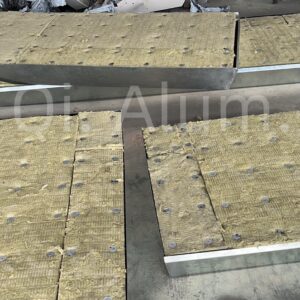

In an era where architecture demands both aesthetic excellence and uncompromising functionality, Aluminum Shadow Box Systems integrated with aluminum rock wool panels are redefining the boundaries of modern construction. These innovative systems combine precision-engineered aluminum framing with advanced fire-resistant insulation, offering architects and engineers a holistic solution for sustainable, safe, and visually dynamic buildings.

Why Aluminum Shadow Box & Rock Wool Panels?

- Unmatched Fire Safety

- Achieves Class A1 Fire Rating (EN 13501-1) with non-combustible rock wool cores, critical for high-rises and public spaces.

- Prevents flame spread and toxic smoke emission, exceeding ASTM E119 3-hour fire endurance standards.

- Thermal & Acoustic Supremacy

- 0.22 W/m·K Thermal Conductivity minimizes energy loss, reducing HVAC costs by up to 40% in extreme climates.

- 55 dB Sound Reduction (ISO 10140-2) creates silent zones for hospitals, studios, and urban residences.

- Corrosion-Resistant Durability

- Marine-grade aluminum alloys with PVDF coatings withstand salt spray (ASTM B117), UV radiation, and -40°C to +120°C thermal cycling.

- Maintenance-free lifespan exceeding 50 years, validated by accelerated weathering tests (ISO 9227).

Architectural Applications Transforming Industries

Architectural Applications Transforming Industries

1. Commercial Skyscrapers

- Case Study: Dubai’s SkyTower

Aluminum Shadow Box cladding with 200mm rock wool insulation reduced cooling loads by 35%, while its parametric shadow gaps created iconic light patterns. Key metrics:- Wind Load Resistance: 7,500 Pa (EN 1991-1-4)

- Condensation Control: Dew point analysis via CFD simulation

2. Healthcare Facilities

- Hospital ICU Walls

Seamless Aluminum Shadow Box partitions with:- ISO 5 Cleanroom Certification: Antimicrobial anodized surfaces

- EMI Shielding: Protects sensitive MRI equipment

- Quick-Disassembly Panels: For sterile zone maintenance

3. Industrial Complexes

- Oil & Gas Plant Firewalls

Custom explosion-resistant panels featuring:- EN 13381-8 Certified structural fire protection

- Modular Installation: 60% faster than traditional concrete barriers

Sustainability at Its Core

- Circular Design: 98% recyclable materials (Declare Label certified)

- Carbon Neutral Production: Powered by renewable energy (ISO 14064-1 verified)

- LEED v4.1 Contributions:

- MRc1: 30% recycled aluminum content

- EQc3: Zero VOC emission assemblies

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!