Description

Aluminum mesh, crafted from aluminum or its alloys, has emerged as a highly versatile material across numerous industries. Its unique combination of properties, such as lightweight, durability, corrosion resistance, and aesthetic appeal, makes it an attractive choice for a wide range of applications. This article delves into the various aspects of aluminum mesh, including its manufacturing methods, types, characteristics, applications, and market trends.

One common way to produce aluminum mesh is through welding. In this process, aluminum wires or strips are joined together at their intersection points using welding techniques. This method allows for the creation of a wide variety of mesh patterns, depending on the arrangement of the wires and the welding process employed. Welding can be used to produce both simple and complex mesh designs, and it offers good strength and stability to the resulting mesh structure.

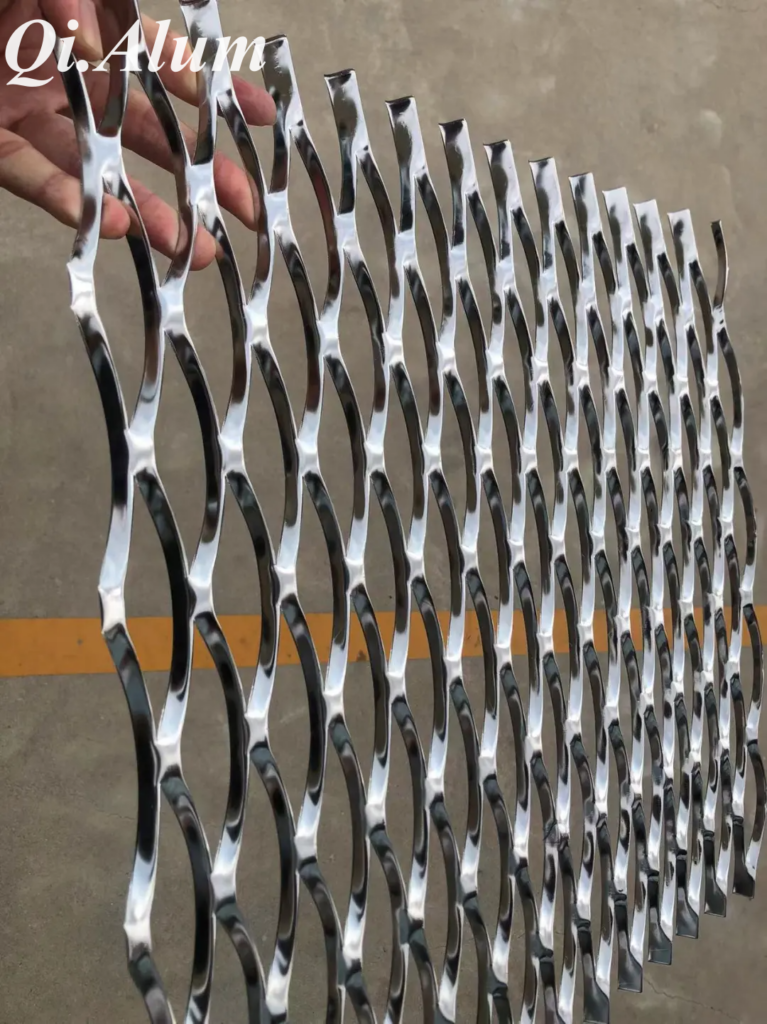

Weaving is another prevalent manufacturing method for aluminum mesh. Similar to traditional fabric weaving, aluminum wires are interlaced over and under each other to form a mesh pattern. This technique can produce very fine and intricate meshes, with precise control over the size and shape of the openings. Weaved aluminum mesh often exhibits excellent flexibility, which is beneficial for applications where the mesh needs to conform to irregular surfaces or be bent into specific shapes.

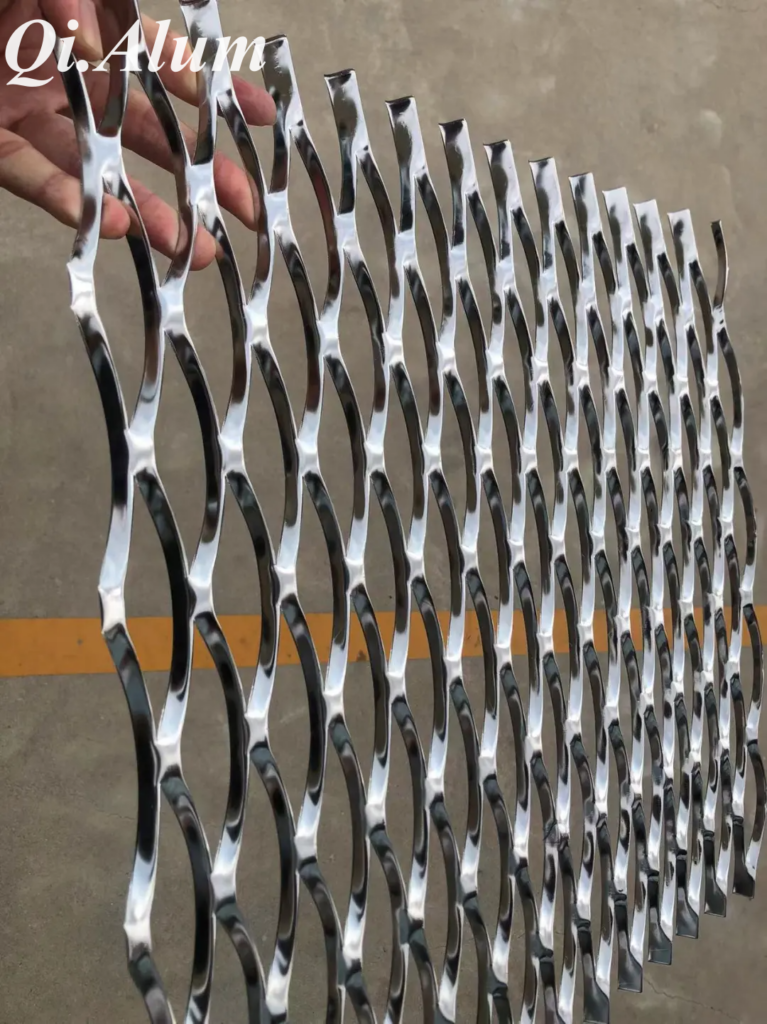

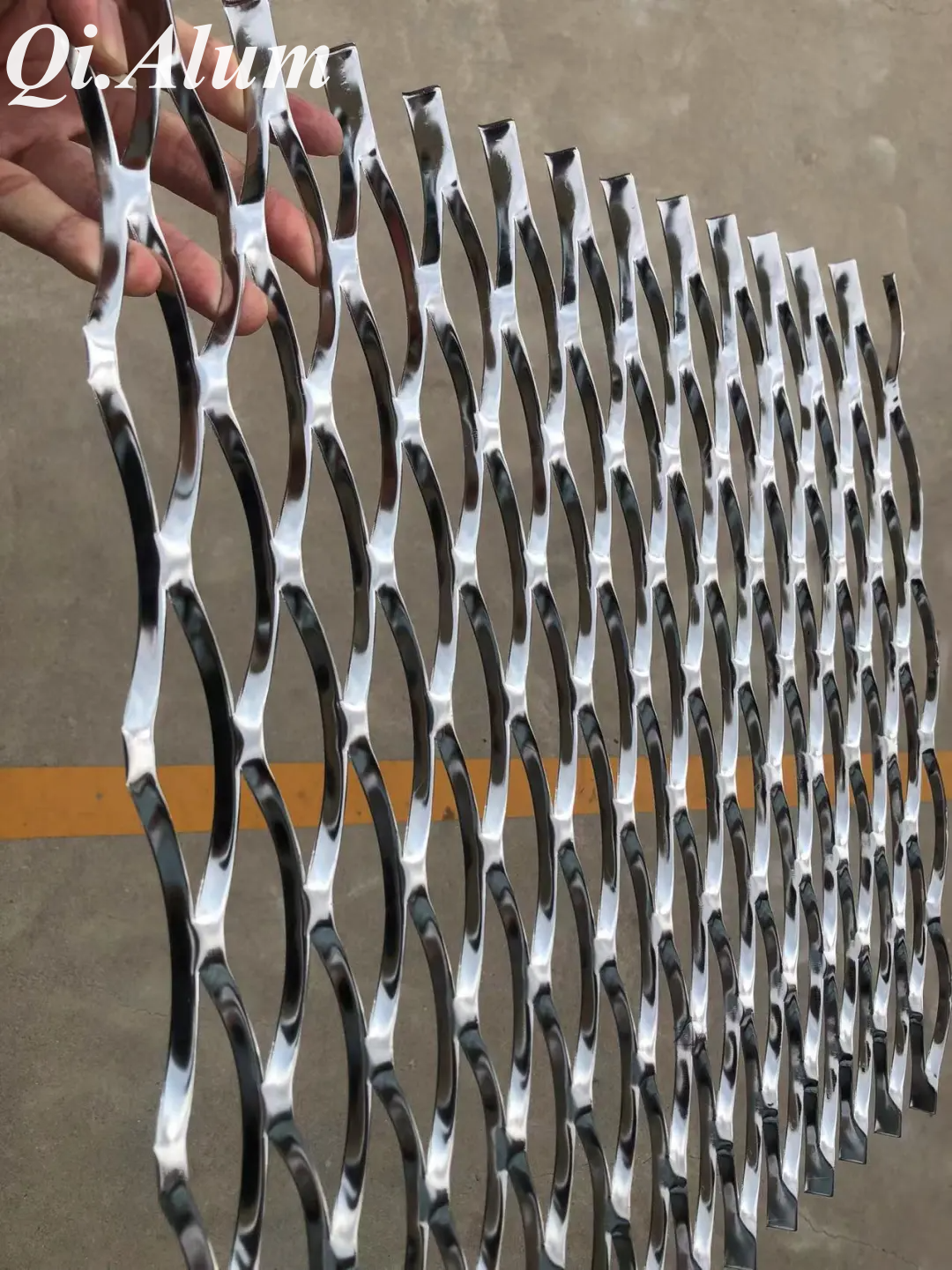

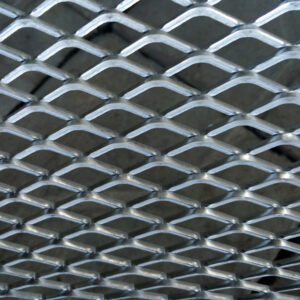

The expanding method involves starting with a solid aluminum sheet. The sheet is first slit in a specific pattern and then stretched. As the sheet is stretched, the slits open up, creating a mesh – like structure with diamond – shaped or other geometrically – shaped openings. This process results in a strong and continuous mesh, as the strands of the mesh are an integral part of the original sheet, without any separate joining points. Expanded aluminum mesh is known for its high strength – to – weight ratio and is commonly used in applications where structural integrity is crucial.

Aluminum meshes made from 1050 and 1060 alloys are highly pure, with an aluminum content of up to 99.5% and 99.6% respectively. These meshes offer excellent electrical conductivity, which makes them ideal for applications in the electrical industry, such as in electromagnetic shielding for electronic devices. Their high thermal conductivity also allows for efficient heat dissipation, so they can be used in heat sinks or cooling systems. Additionally, they have good corrosion resistance, which is beneficial for outdoor applications or in environments with mild corrosive substances. However, their relatively low strength limits their use in applications that require high – load bearing capabilities.

The 3003 aluminum mesh contains manganese as the main alloying element. This addition significantly improves the strength of the mesh compared to the pure aluminum counterparts while still maintaining good corrosion resistance and workability. 3003 aluminum mesh is often used in construction applications, such as for building facades, where it can provide both an aesthetically pleasing appearance and a certain level of structural support. It can also be found in ventilation systems, as its mesh structure allows for proper air circulation while being able to withstand normal environmental conditions.

5052 aluminum mesh contains magnesium as the primary alloying element. This alloy provides high strength, especially in the face of corrosion, making it suitable for harsh environments. In the marine industry, it is used for applications such as shipboard ventilation systems, where it needs to resist the corrosive effects of saltwater. In the automotive industry, 5052 aluminum mesh can be found in radiator guards, as it can protect the radiator from debris while withstanding the vibrations and environmental factors associated with vehicle operation.

Aluminum itself is a lightweight metal, and aluminum mesh inherits this property. This makes it an attractive option in applications where weight is a critical factor, such as in the aerospace industry. In aircraft, every reduction in weight can lead to significant fuel savings. Aluminum mesh can be used in aircraft interior components, like ventilation grilles or partition screens, where its lightweight nature helps to reduce the overall weight of the aircraft without sacrificing functionality. In the construction of high – rise buildings, lightweight aluminum mesh can be used for curtain walls, reducing the load on the building structure.

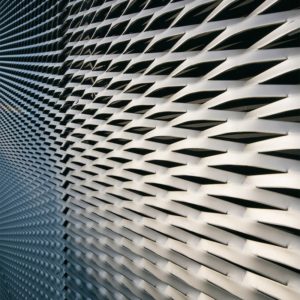

Despite its lightweight, aluminum mesh is quite durable. The metal’s natural oxide layer provides some protection against corrosion. Additionally, through processes like anodizing or powder coating, the durability can be further enhanced. In industrial settings, aluminum mesh is used in equipment guards and safety barriers, where it needs to withstand continuous use, impacts from small objects, and exposure to various environmental conditions over an extended period. In outdoor architectural applications, such as fences or decorative screens, the durability of aluminum mesh ensures a long – lasting and low – maintenance solution.

Aluminum forms a thin, self – healing oxide layer when exposed to air. This oxide layer acts as a barrier, preventing further oxidation and corrosion. This property makes aluminum mesh suitable for outdoor applications, such as in garden fences, where it is constantly exposed to moisture, sunlight, and temperature variations. In coastal areas, where the air contains salt particles, aluminum mesh can be used for building facades or window screens without the worry of rusting, unlike some other metal meshes. In the food and beverage industry, where hygiene and resistance to corrosion from cleaning agents are important, aluminum mesh is used in filtration systems and conveyor belts.

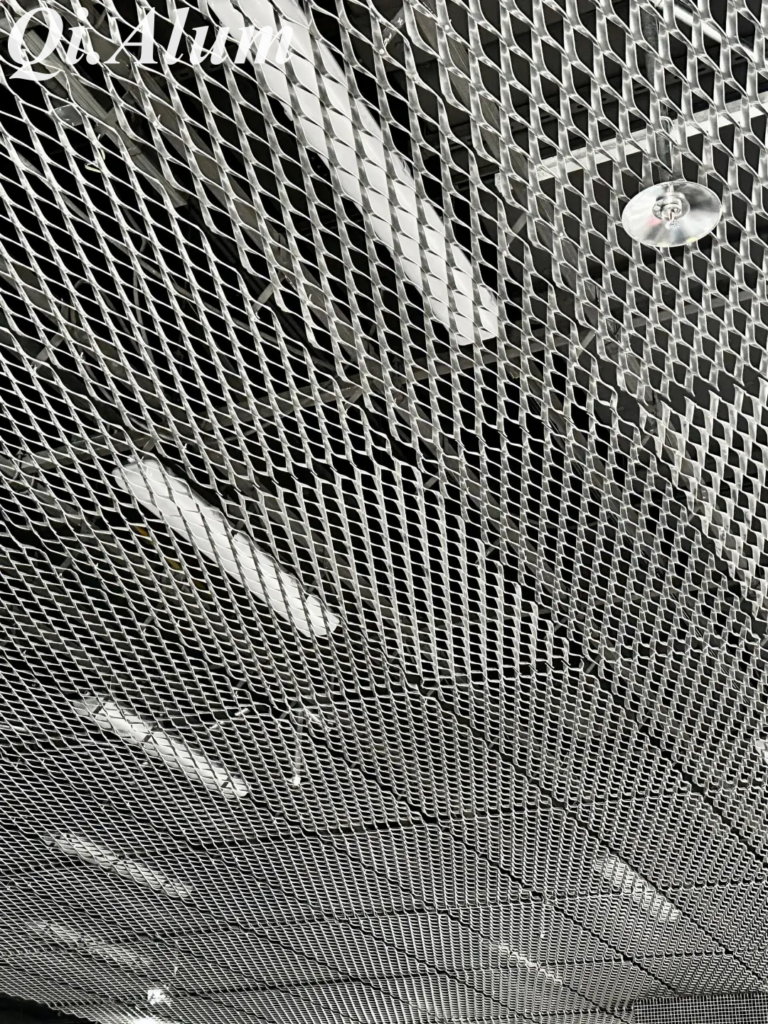

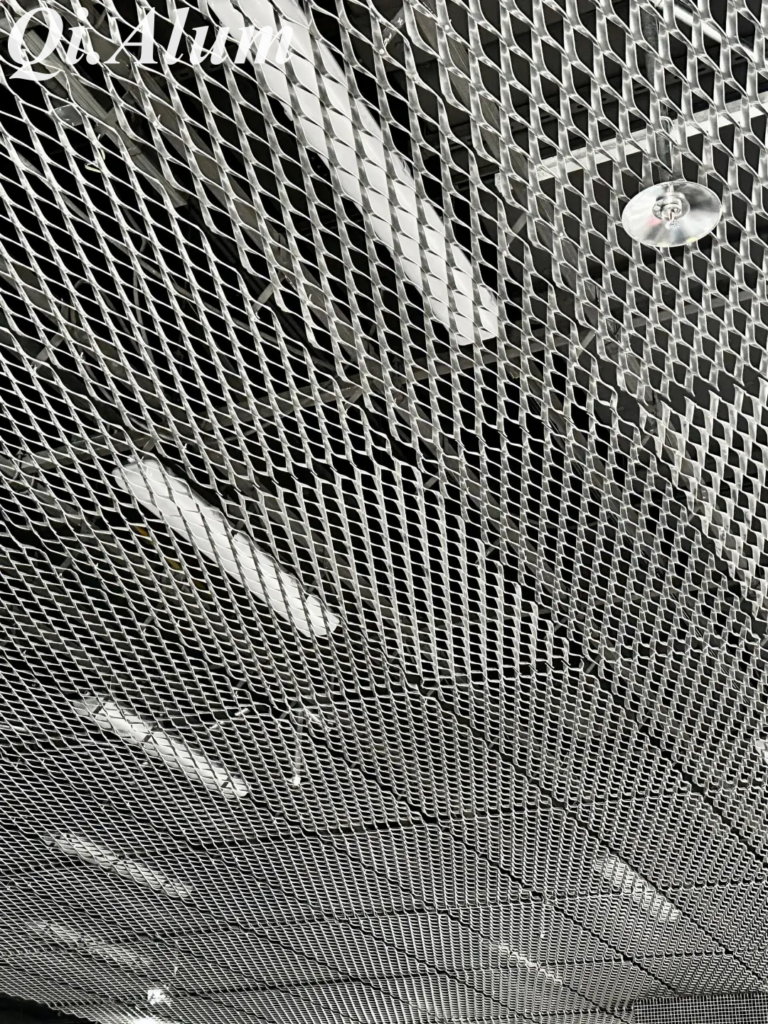

Aluminum mesh comes in a variety of patterns, sizes, and finishes, offering great aesthetic flexibility. It can be used to create modern and sleek designs in architecture. For example, in contemporary building facades, aluminum mesh can be used to create unique visual effects, either by itself or in combination with glass or other building materials. The mesh can be powder – coated in different colors to match the overall design scheme of a building. In interior design, aluminum mesh can be used for decorative room dividers, adding a touch of elegance and sophistication. It can also be used in lighting fixtures, where the mesh pattern can create interesting shadow effects when the light shines through.

The open – mesh structure of aluminum mesh allows for good permeability of air, light, and even liquids in some cases. In ventilation systems, this property is crucial as it enables proper air circulation. For example, in industrial kitchens, aluminum mesh is used in exhaust hoods to filter out grease and other particles while allowing the hot air to escape. In greenhouse applications, aluminum mesh can be used as a shading material. It can block a certain amount of sunlight, reducing the intensity of light inside the greenhouse, while still allowing air to flow freely, which is important for plant growth. In water filtration systems, specific types of aluminum mesh can be used to filter out impurities while allowing the water to pass through.

- Facades and Curtain Walls: Aluminum mesh is increasingly used in building facades and curtain walls. It can add a unique texture and visual interest to the building’s exterior. In addition to its aesthetic function, it can also provide some level of sun shading, reducing the amount of direct sunlight entering the building and thus helping with energy efficiency. For example, in modern office buildings, aluminum mesh curtain walls can create a sleek and contemporary look while also contributing to a more comfortable indoor environment.

- Interior Decoration: Inside buildings, aluminum mesh is used for a variety of decorative purposes. It can be used to create room dividers, which not only separate spaces but also allow for a certain degree of visual connection. In hotels or high – end restaurants, aluminum mesh partitions can add a touch of elegance. It can also be used for ceiling designs, where it can create an open and airy feel, while also being able to hide wiring and other utilities.

- Safety and Security: Aluminum mesh is used in safety barriers and fences. In industrial plants, it can be used to create barriers around machinery to prevent workers from accidentally coming into contact with moving parts. In residential areas, aluminum mesh fences can provide a certain level of security while still maintaining an open and unobtrusive look. Additionally, in some high – security areas, such as around government buildings or data centers, aluminum mesh can be incorporated into security systems, providing both a physical and visual deterrent.

- Radiator Guards: Aluminum mesh is commonly used in radiator guards. It protects the radiator from debris, such as stones, bugs, and leaves, which could potentially damage the radiator fins and reduce its cooling efficiency. The lightweight nature of aluminum mesh is beneficial as it does not add significant weight to the vehicle, and its corrosion resistance ensures a long service life, even in harsh driving conditions.

- Interior Components: In the automotive interior, aluminum mesh can be used for decorative elements, such as on dashboard vents or door panels. It can add a sporty or luxurious look to the vehicle’s interior. Additionally, in some high – performance cars, aluminum mesh may be used in ventilation systems to ensure proper air circulation within the engine compartment or the passenger cabin.

- Filtration Systems: In industrial processes, aluminum mesh is widely used in filtration systems. In the chemical industry, it can be used to filter liquids and gases, separating out impurities and ensuring the quality of the final product. For example, in the production of pharmaceuticals, aluminum mesh filters are used to remove any particulate matter from the liquid medications. In the oil and gas industry, aluminum mesh is used in filtration systems to clean the fuel or gas before it is used in engines or other equipment.

- Equipment Guards: Aluminum mesh is used to create guards for industrial equipment. It can protect workers from the moving parts of machinery, such as conveyor belts, gears, and pulleys. The mesh allows for visibility, so workers can still see the equipment in operation, while also providing a physical barrier to prevent accidental contact. In addition, the durability of aluminum mesh ensures that it can withstand the harsh conditions of an industrial environment, such as exposure to dust, dirt, and vibrations.

- Greenhouse Shading and Insect Control: In agriculture, aluminum mesh is used in greenhouses. It can be used as a shading material to regulate the amount of sunlight that enters the greenhouse. By adjusting the density and size of the mesh, farmers can control the light intensity, which is important for the growth of different types of plants. Additionally, aluminum mesh can be used to keep insects out of the greenhouse. The small openings in the mesh prevent insects from entering, reducing the need for pesticides and protecting the plants from insect – borne diseases.

- Animal Enclosures: Aluminum mesh is also used in animal enclosures. It can be used to create fences or cages for livestock or poultry. The lightweight nature of aluminum makes it easy to install and move if needed. The corrosion resistance of aluminum ensures that the enclosures can withstand the outdoor elements and the corrosive substances present in animal waste.

- Electromagnetic Shielding: Aluminum mesh is used in electronic devices for electromagnetic shielding. In today’s world, where electronic devices are everywhere, electromagnetic interference (EMI) can cause problems with the proper functioning of these devices. Aluminum mesh, due to its good electrical conductivity, can be used to create a shield around electronic components, preventing EMI from entering or leaving the device. For example, in smartphones, aluminum mesh may be used in the casing to shield the internal components from external electromagnetic fields.

- Heat Dissipation: In some electronic devices, such as computers and servers, aluminum mesh can be used as part of the heat dissipation system. The high thermal conductivity of aluminum allows it to efficiently transfer heat away from the components, preventing overheating. The mesh structure also allows for better air circulation around the heat – generating components, further enhancing the cooling effect.

The global aluminum mesh market has been experiencing steady growth in recent years. This growth is driven by several factors. Firstly, the increasing demand for lightweight materials in various industries, such as automotive and aerospace, is fueling the demand for aluminum mesh. As these industries strive to improve fuel efficiency and reduce emissions, the use of lightweight materials like aluminum mesh becomes more appealing.

Secondly, the construction industry’s growth, especially in emerging economies, is also contributing to the market expansion. With the increasing urbanization and the construction of new buildings, there is a growing need for aesthetically pleasing and functional building materials, and aluminum mesh fits the bill.

Moreover, the development of new and improved manufacturing processes for aluminum mesh is leading to better – quality products and more customization options. This is attracting more customers from different industries, further driving the market growth.

In terms of regional markets, Asia – Pacific is expected to be a major growth driver. The rapid industrialization and urbanization in countries like China, India, and Southeast Asian nations are creating a high demand for aluminum mesh in construction, automotive, and industrial applications. North America and Europe also have significant markets, with a focus on innovation and the use of sustainable materials, where aluminum mesh, being recyclable, fits well into these trends.

Aluminum mesh is a highly versatile and valuable material with a wide range of applications across multiple industries. Its unique combination of properties, including lightweight, durability, corrosion resistance, aesthetic appeal, and good permeability, makes it an ideal choice for various uses. As manufacturing processes continue to improve and market demand grows, especially in sectors like automotive, construction, and electronics, aluminum mesh is likely to play an even more significant role in the future. Whether it’s enhancing the performance of a vehicle, adding an elegant touch to a building, or ensuring the proper functioning of industrial equipment, aluminum mesh proves to be an essential material in modern manufacturing and design.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!