Description

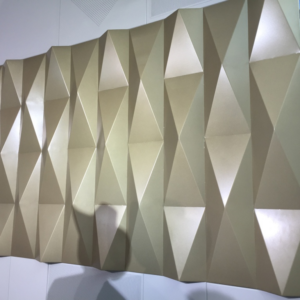

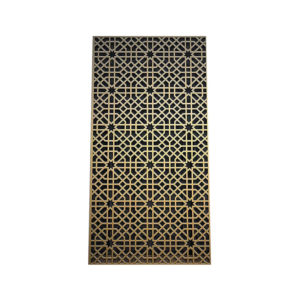

Aluminium alloy material wall cladding perforated panel for building decorative

Description

| Main Service | Custom Fabrication to Drawings,Design,Sketch or Idea |

| Material | Carbon Steel, Stainless Steel, Aluminium, Pregalvanized Sheet, Corten Steel,etc. |

| Finish | Powder Coating, Painting, Plating, Anodizing, Galvanizing, Polish, Sand Blasting,etc. |

| Thickness | As Requirement |

| Processing | Laser Cut, NCT Punch, Stamping or Pressing, Bending, Welding, Grinding, Tapping, Machining, Finishing, Assembling, etc. |

| Feature | High Precision

Superior Workmanship Excellent Assembly Relationship High Quality Surface Treatment |

| Processing Type | CNC Precise Processing |

| Advantage | More than 20 Years Experience

Skillful Sales Representative Professional Production Staff Punctual Delivery Good Quality |

Specification of Aluminium Perforated Panel:

1. High impact strength

2. Fast & easy installation

3. Corrosion & duct proof

4. Rain & UV resistant

5. Variety shape & color

6. Environmental protection

7. 100% recyclable

How Is Aluminum Perforated Panels Made?

The manufacturing process for aluminum perforated paneling starts with sheet metal. Sheet metal is thin flat, and can be cut and bent into different shapes. In many area of the world, sheet metal thickness is measured in millimeters.

Another common method is “die and punch” perforating. During this process, a sheet with needles is repeatedly pressed onto the passing metal which punches holes into the sheet. The pieces remaining from the punching are then sheared off and the surface is smoothed.

Packing

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request.

FAQs

Q: Which perforated sheet materials are rust resistant?

A: Perforated aluminum, stainless steel, and galvanized perforated steel are the most rust resistant materials that we perforate.

Q: Why is perforated sheet commonly used?

A: Perforated sheet is used for a variety of applications because of the hole size options, percentage of open area, high strength- to-weight ratio, and aesthetic appeal.

Q: Can I choose the material type for my perforated metal sheet?

A: Yes, there are many material options for your perforated sheet order. Perforated steel comes in both stainless perforated steel and carbon perforated steel. You can also choose aluminum perforated sheet. If you need help deciding between perforated steel, perforated aluminum, and other material options, you can learn more in our Perforated Metal Catalog.