Description

Here are some methods to judge the corrosion resistance of aluminum air conditioner covers:

- Anodizing Treatment: The aluminum air conditioner cover treated by anodizing will form a hard, wear-resistant and corrosion-resistant oxide film on its surface. This oxide film can effectively prevent the external substances from eroding the aluminum substrate and improve the corrosion resistance. Generally speaking, the thicker the oxide film, the stronger the corrosion resistance. The thickness of the high-quality anodized film can reach more than 10μm.

- Fluorocarbon Coating Treatment: The fluorocarbon coating has excellent weather resistance and corrosion resistance, and can resist the erosion of acid rain, salt spray and other harsh environments. To judge the quality of fluorocarbon spraying, you can check whether the coating is uniform and smooth, without bubbles, flow marks and other defects. Moreover, the high-quality fluorocarbon sprayed aluminum air conditioner cover can pass the neutral salt spray test for more than 2000 hours.

- Test Standard: The salt spray test is a common method to evaluate the corrosion resistance of metal materials. You can refer to the national standard GB/T 10125 “Artificial Atmosphere Corrosion Test – Salt Spray Test”. Generally, the aluminum air conditioner cover used outdoors should at least pass the 500-hour neutral salt spray test. If it can reach 1000 hours or even longer, it indicates that its corrosion resistance is more excellent.

- Test Results: If the aluminum air conditioner cover product has a clear salt spray test report or relevant data, it can be directly used as an important basis for judging its corrosion resistance. For example, some high-quality aluminum air conditioner covers can show no obvious signs of corrosion after more than 2000 hours of salt spray test, indicating that they have strong corrosion resistance.

- Climate Conditions: If the aluminum air conditioner cover will be used in coastal areas with high salinity and humidity, or in areas with serious industrial pollution and frequent acid rain, the requirements for its corrosion resistance will be higher. If the aluminum air conditioner cover used in these harsh environments can still maintain a good appearance and performance, without obvious corrosion, fading, deformation and other problems after a period of time, it means that its corrosion resistance is good.

- Installation Location: The aluminum air conditioner cover installed in high-rise buildings, open areas and other positions that are easily exposed to wind, sun and rain needs to have stronger weather resistance and corrosion resistance than that installed in relatively hidden positions. Therefore, it is also important to evaluate the corrosion resistance of the air conditioner cover in combination with its installation position.

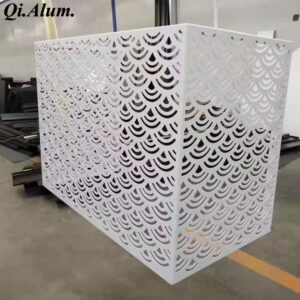

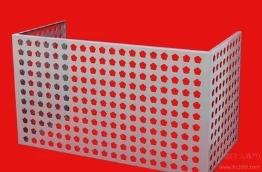

- Surface Quality: Carefully check whether there are scratches, bumps, pores and other defects on the surface of the aluminum air conditioner cover, because these defects will damage the oxide film or coating on the aluminum surface, expose the internal aluminum to the external environment, thereby reducing the corrosion resistance and easily leading to the spread of corrosion from these defects.

- Edge Treatment: The high-quality aluminum air conditioner cover will be specially treated at the edges, such as folding, sealing, etc., to prevent water and corrosive substances from infiltrating into the interior from the edges and affecting the service life. The aluminum air conditioner cover with good edge treatment has relatively more guaranteed corrosion resistance.

- Well-known Brands: Choose well-known brands and aluminum air conditioner covers with good reputation, usually their product quality and corrosion resistance are more guaranteed. Some well-known brands will strictly control the quality of raw materials, surface treatment processes and other links in the production process to ensure that the products have better corrosion resistance.

- Aluminum Alloy Material: Different types of aluminum alloy materials have different corrosion resistances. For example, aluminum-magnesium alloy has better corrosion resistance and strength, while aluminum alloy with a high copper content may be more prone to corrosion in some environments. Therefore, understanding the composition of the aluminum alloy material used for the aluminum air conditioner cover is also helpful for preliminarily judging its corrosion resistance.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

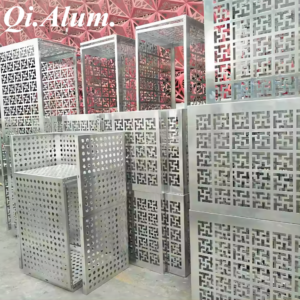

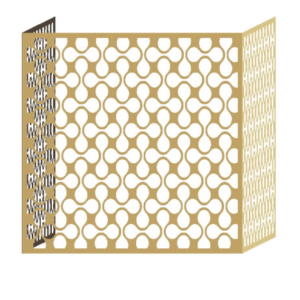

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!