Description

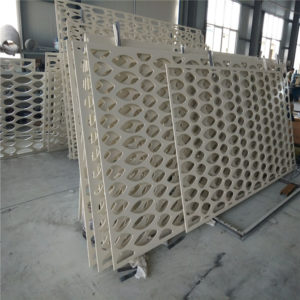

JOTUN Powder coating Aluminum Perforated Panel

| Business Type | Manufacturer & Trading Company | |

| Material Grade | 6000 Series Aluminium Alloy | |

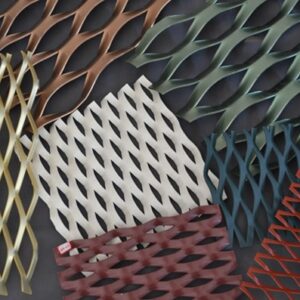

| Surface Treatment | Mill finish, Anodizing, Eletrophoresis, Sand Blasting, Powder Coating, PVDF, Wooden Grain, Polishing, Thermal Break, etc. | |

| Further Process Ability | Drilling, Welding, Precise Cutting, Punching, Fabrication of windows and doors, etc. | |

| Specifications | Alloy: 6063, 6061 etc. | |

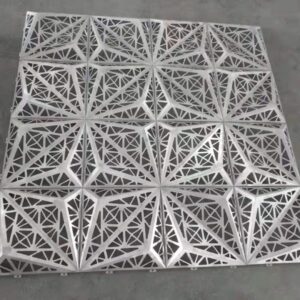

| Designs and tolerances | As per customized drawings or samples. | |

| Dies | Making moulds and producing as per desgined drawing | |

| 1. If using our existing moulds, NO extra charge. | ||

| 2. If opening new mould, the mould cost can be refunded when cumulative output quantity reach a certain ton. | ||

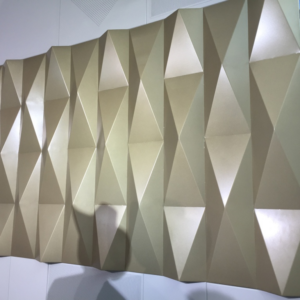

| Application | Mainly used for Windows and Doors, Curtain Wall, Kitchen Cabinet, Wardrobe, Decoration and Industrial etc. | |

| Quality Control | 1. Inspection on raw materials;

2. Process inspection at Site beside production line. 3. Finished Product inspection before packaging. |

|

| Normal Order Sequence | 1.Confirm the drawings, treatment colors and price. | 2. Start to make new moulds after receiving mould cost. |

| 3. Sending new samples to customer for confirmation. | 4. Start production once received 30% deposit from customer. | |

| Payment Term | T/T, L/C | |

| Minimum Order Quantity | 100 Square meter | |

| Delivery Date | 15-25 days after receiving 30% deposit | |

Why choose Perforated Panels for your project

· Perforated panels provides a lightweight and aesthetic solution, especially for solar shading and cladding purposes, as it allows natural light and air to penetrate. Moreover, interesting patterns and designs can be created hence creating an exterior that is both aesthetic and functional at the same time.

· Cost effective solution to breathe new life into old buildings as well as provide a uniform and aesthetic outer structure for exterior facades.

· Using perforated panels in indoor places ensures that unwanted sound reflections can be efficiently absorbed and the reverberant noise that interferes with the required audio is reduced. Adequate absorption of unnecessary sounds is essential for providing an optimal acoustical experience in large halls and crowded places like classrooms, conference rooms, auditoriums, theatres and restaurants.