Description

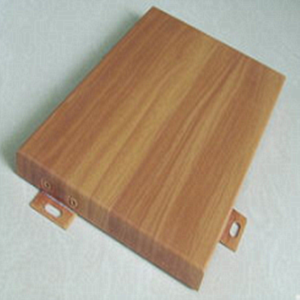

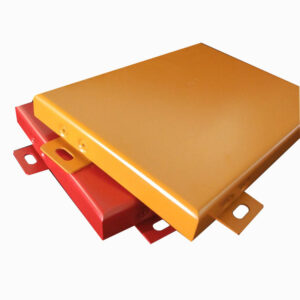

Renowned brands usually adhere to stricter standards in manufacturing processes and raw material selection. Their products are of higher quality. For instance, some well – reputed brands in the industry produce PVDF – coated aluminum single – layer panels with excellent adhesion and uniformity of the PVDF coating. This enables the panels to better resist external environmental erosion, reducing the increase in maintenance costs caused by premature coating damage.

Opt for PVDF – coated aluminum single – layer panels that meet relevant national and industry standards. For example, national standards clearly define requirements for the thickness, hardness, and weather resistance of the PVDF coating. Products that meet these standards can maintain good performance for an extended period under normal usage conditions, reducing the frequency of maintenance.

Employ experienced and professional installation teams to ensure the accurate installation of PVDF – coated aluminum single – layer panels. Incorrect installation can lead to problems such as uneven gaps between panels and uneven stress distribution, accelerating the damage of the panels. For example, if the flatness of the panels is not ensured during installation, the local stress concentration may cause the coating to crack in subsequent use, increasing maintenance costs.

Strictly follow the product installation instructions and relevant specifications. For example, when installing, leave appropriate expansion joints to accommodate the thermal expansion and contraction of PVDF – coated aluminum single – layer panels in different temperature environments. This can prevent panel deformation and detachment due to temperature changes, reducing the likelihood of maintenance and repair.

Develop a regular cleaning plan, typically conducting a comprehensive cleaning every quarter or half a year. Use mild cleaning agents and soft cleaning tools. For example, wipe with a neutral detergent solution and a soft cloth, avoiding the use of cleaning agents containing abrasives, strong acids, or strong alkalis to prevent damage to the PVDF coating. Regular cleaning can promptly remove dust, dirt, acid rain, and other corrosive substances on the surface, maintaining the aesthetics and performance of the panels and extending their service life.

Deal with minor stains found in daily life in a timely manner. For common stains such as fingerprints and dust, wipe them clean immediately with a clean, damp cloth. This prevents the stains from adhering to the surface for an extended period and penetrating into the coating, which could increase the difficulty of cleaning and maintenance costs.

Regularly inspect the appearance of PVDF – coated aluminum single – layer panels for signs of coating peeling, scratching, discoloration, etc. If small – area coating damage is detected, repair it promptly to prevent the damaged area from expanding. For example, for minor scratches, use special PVDF paint for repair to avoid rusting and corrosion at the scratched areas, which could affect the overall service life of the panel.

In addition to appearance inspection, also check the installation structure of PVDF – coated aluminum single – layer panels. Look for loose fixing screws, deformed connectors, etc. If structural problems are found, repair and reinforce them in a timely manner. This can prevent safety accidents such as panel detachment due to structural instability and also avoid other damages caused by structural problems, reducing maintenance costs.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

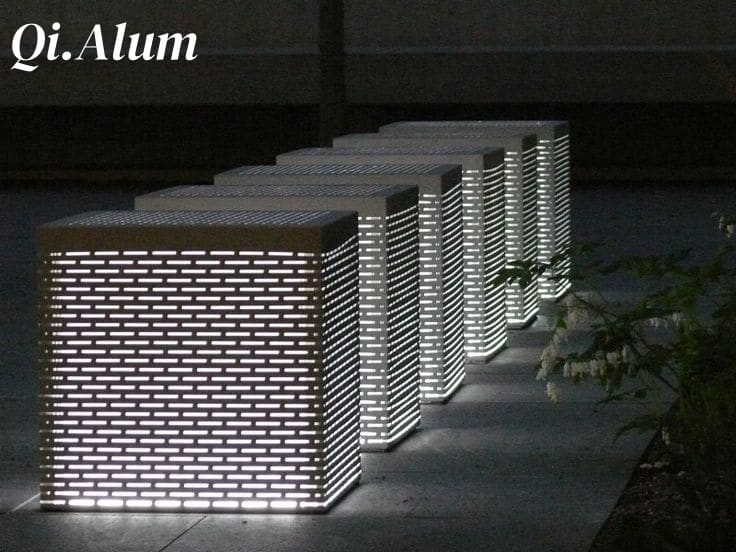

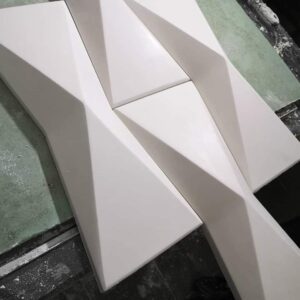

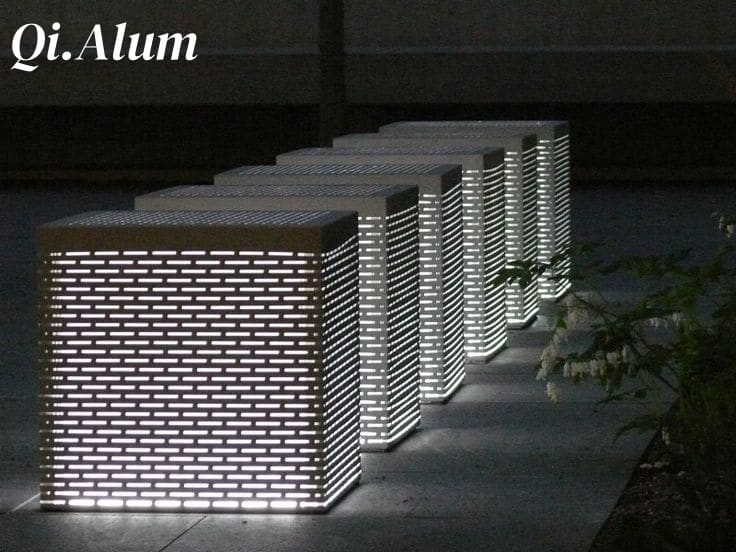

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!