Description

Design and Drawing Confirmation

- Requirement Communication: Communicate fully with clients and designers to understand the specific requirements for double – curved aluminum plates in the construction project, including details such as shape, size, curvature, color, surface treatment, etc., and clarify the usage scenarios and functional requirements.

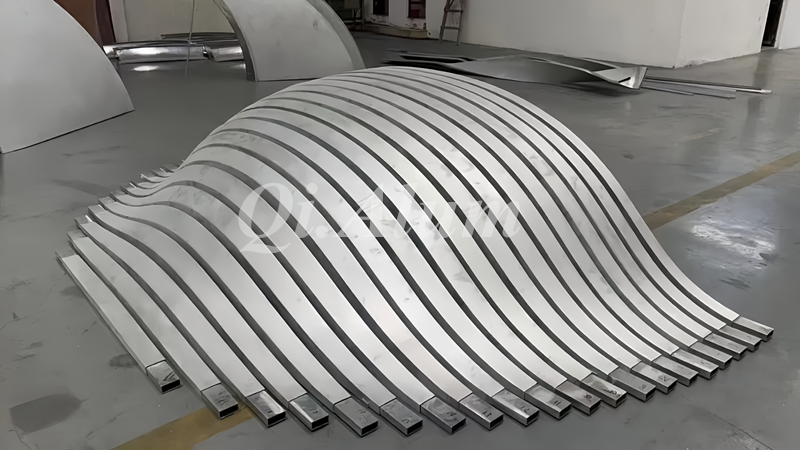

- 3D Modeling: Utilize professional 3D design software (such as Rhino, 3ds Max, etc.) to create an accurate 3D model of the double – curved aluminum plate according to the project requirements. During the modeling process, precisely adjust various parameters of the double – curved aluminum plate to ensure that its shape and size meet the design intention.

- Drawing Preparation: Generate detailed 2D engineering drawings based on the 3D model, marking key dimensions, tolerance ranges, processing requirements, surface treatment information, etc. The drawings need to be reviewed and confirmed by multiple parties to ensure accuracy and serve as the basis for subsequent processing.

Raw Material Procurement and Inspection

- Material Selection: Select appropriate aluminum alloy materials according to the usage requirements and performance characteristics of double – curved aluminum plates. Common materials include 3003, 5052, 6061, etc. Consider factors such as material strength, hardness, corrosion resistance, and machinability to ensure that the materials can meet the processing and usage requirements.

- Quality Inspection: Conduct strict quality inspections on the purchased aluminum alloy plates, including checking whether the specifications and dimensions, flatness, chemical composition, mechanical properties, etc. of the plates meet the standard requirements. Use professional testing equipment and methods, such as calipers for measuring dimensions, spectrometers for detecting chemical composition, and universal testing machines for testing mechanical properties, etc., to ensure the quality of raw materials is qualified.

Cutting and Blanking

- Cutting Programming: According to the dimensional requirements of the engineering drawings, use CNC cutting programming software to convert the cutting path of the double – curved aluminum plate.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!