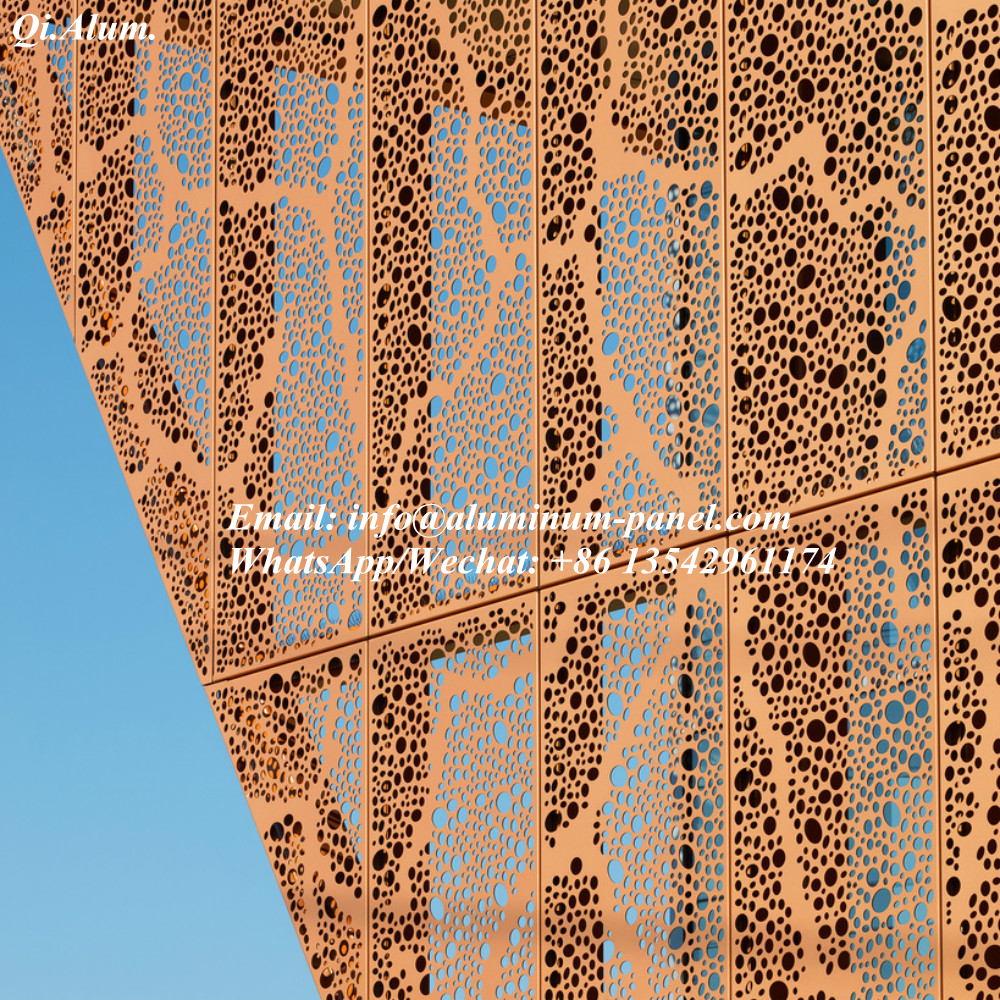

Hollow aluminum sheet is a high-grade aluminum alloy as the main materials, according to the size, shape and structure of engineering site design form after CNC bending technologies such as molding, ensure smooth deformation plate after processing, and fluorine carbon spraying on the surface on the basis of making consistent grid spacing ratio size of a metal decorative materials, makes the Seine aluminum sheet can meet customer requirements.

Hollow art pattern aluminum sheet compared with the general specifications of aluminum sheet can meet customers’ pursuit of beauty, size, color, spacing, etc., can be customized according to customer needs.

1, punching aluminum sheet system uses aluminum alloy panel as the base material, CNC bending technology, to ensure that the plate can be flat after processing without deformation, in the aluminum panel installation process anti-external force performance. Fireproof aluminum sheet system adopts the bacterium of fluorine carbon spraying equipment and surface coating akzo fluorocarbon (PVDF) coating in the United States, ensure that the surface colour and lustre is uniform, resistance to ultraviolet radiation, oxidation resistance, corrosion resistance, aluminum sheet production center processing is strong, strong technical strength, with more than one German CNC shearing machine, CNC bending machine and the stud welding machine, Sophisticated equipment skilled workers, is the domestic special-shaped plate processing manufacturers.

- The base material of hollow aluminum sheet system is selected 3003 aluminum manganese alloy or 5052 aluminum magnesium alloy plate, so the tensile strength and yield strength of aluminum plate are stronger than other kinds of aluminum plate.

- The punching aluminum sheet system is mainly composed of panels, stiffeners and corner codes. Maximum size of aluminum sheet up to 8000mm×1800mm (length × width)

4, hollow aluminum sheet system coating using PPG, Valspar USA, Netherlands AkzoNobel AkzoNobel, Korea KCC and other brand coatings, coating is divided into two coated with a roast, three coated with two roast, The coating properties meet the AAMA (American Building Manufacturers Association) and ASCA (American Building Spraying Association) AAMA2605-98 standards.

5, Guangdong hollow aluminum sheet system plate conventional thickness: 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm.

6, hollow aluminum sheet system material commonly used specifications: 600600mm, 6001200mm and customized modeling.

二, hollow art pattern aluminum panel processing technology brief introduction

1, as guangdong punching large aluminum panel manufacturer specialized production enterprise, and material co., LTD has imported sheet metal equipment and automatic spraying production line and perfect computer control system, can complete the difficult design scheme of irregular products, realize the diversification of the aluminum sheet products and sex., ltd.can produce aluminum curtain wall plate more than 50 square meters.

System 2, hollow out art design aluminum sheet production by blanking, punching, bending, roll arc, welding, polishing, assembly and so on multi-channel molding process make the product appear all sorts of geometry, the company owns AMADA fully automatic CNC punch press, such as can easily implement all kinds of complex type plate processing, thus to meet the demands of construction and modelling,, Fully express the innovative ideas of architectural design.

3, after the forming of hollow aluminum sheet system, and USES the German technology and pretreatment liquid into processing, forming dense oxide film, be strict surface fluorine carbon spraying, company stop using the full range of Japan’s automatic electrostatic spraying equipment, paint, paint, the paint coat all automatic spray gun, computer control spraying flow rate and scope, Ensure aluminum plate surface film thickness uniformity, and beautiful, the company adopts Italy baked road design and special equipment, to ensure that the furnace temperature curve \ science, after high temperature baking, the molecular structure of the fluorocarbon resin hyperstatic features to full play, make coating surface can resist erosion of external climate for a long time, keep clean as new, use persistent..

4, hollowed-out aluminum panel strict production procedures and quality control, so that the company for many years to obtain the world paint manufacturers PPG licensing, has been proved to be able to strictly implement the PPG industrial standards, to achieve the successful use of DURANAR and DURACRON fluorocarbon paint standards The price

三、 hollow art pattern aluminum sheet production installation method

- Hollow aluminum sheet system is installed according to the same horizontal height.

- Lift light steel keel (38 or 50 keel) according to the appropriate spacing, generally the spacing is 1-1.2 meters, the derrick distance is distributed according to the provisions of light steel keel.

3, hollow aluminum sheet system preinstalled on the aluminum sheet keel hanger, together with the aluminum panel keel close to the light steel keel into a vertical direction under the light steel keel, aluminum panel keel spacing according to the size of the plate to determine, must be adjusted to the level after all installed.

4, the aluminum panel is sequentially buckled on the keel. After each buckle, the reverse lock piece is pressed down, and the keel is connected with connecting pieces.

5, fireproof aluminum sheet system board surface installation must wear gloves, such as inadvertently left fingerprints or stains, available detergent cleaning and wipe dry.

Four, hollow aluminum panel application range

External walls of buildings, beams and columns, balconies

Terminal/terminal

Conference hall, opera House

Sports stadiums, KTV clubs

Reception hall and so on