Description

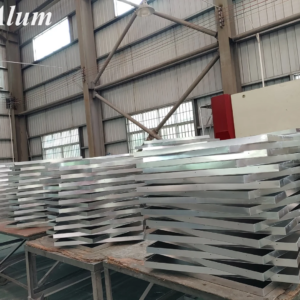

In the realm of modern outdoor architecture, aluminum perforated panels have emerged as a transformative material, seamlessly blending robust functionality with striking visual appeal. Engineered from high-grade aluminum alloys (such as 3003, 5052, or 6061), these panels feature precision-cut perforations that elevate outdoor spaces—from building facades to landscape installations—by balancing weather resistance, design flexibility, and sustainable performance.

Aluminum’s inherent properties make it ideal for outdoor applications:

- Corrosion Resistance: A natural oxide layer protects against moisture, UV radiation, and salt-laden air, with surface treatments like PVDF powder coating (AAMA 2605-certified) extending lifespan to over 25 years in coastal or industrial zones.

- Lightweight Strength: At just 1/3 the weight of steel, panels reduce structural load while maintaining tensile strength (up to 210 MPa), enabling large-scale installations like the curved facades of the Dubai Expo 2020 pavilions.

- Thermal Stability: Resistance to extreme temperatures (-40°C to 80°C) ensures dimensional stability, critical for climates with wide thermal fluctuations.

-

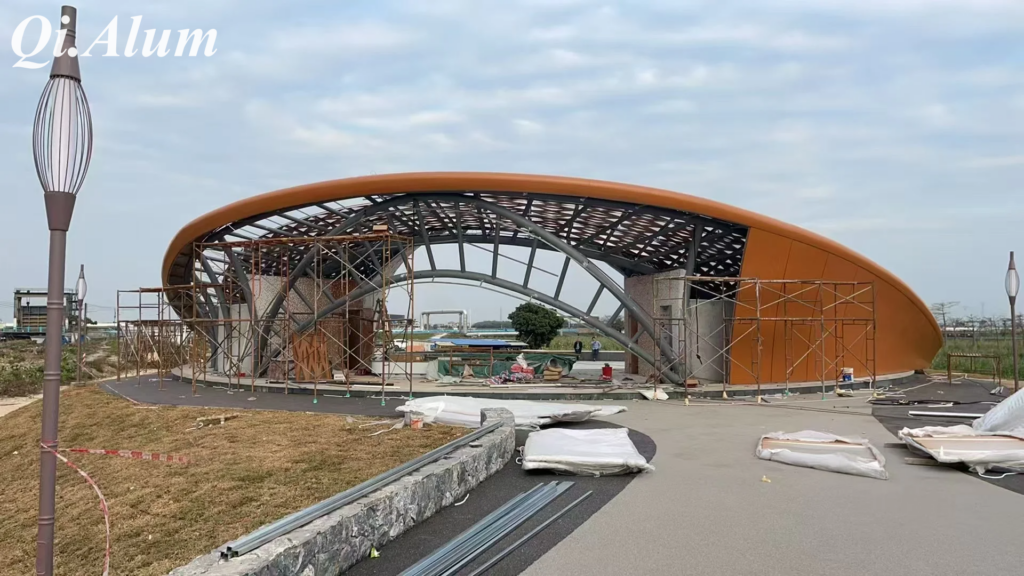

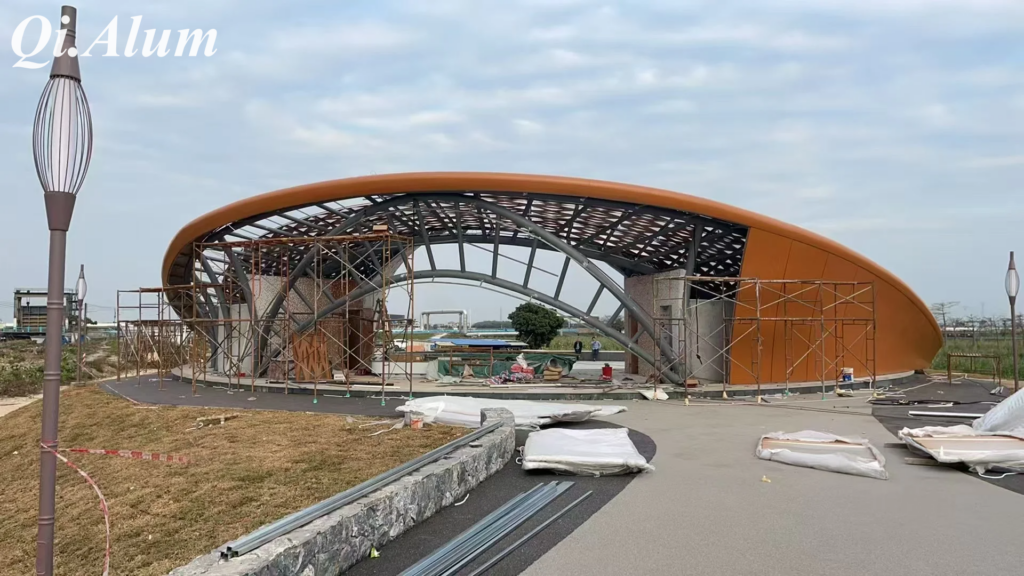

Architectural Facades: Dynamic Skin for Modern Buildings

- Sunshading & Energy Efficiency: Perforations (10–40% open area) filter direct sunlight, reducing solar heat gain by up to 30% and minimizing HVAC loads. For example, the Louvre Abu Dhabi’s iconic dome uses aluminum perforated panels to create a “rain of light” effect while shading interiors.

- Visual Storytelling: Custom patterns—from geometric grids to organic motifs (e.g., leaf or water droplet shapes)—reflect cultural or site-specific narratives. The National Kaohsiung Center for the Arts in Taiwan employs wave-like perforations to mimic the fluidity of nearby rivers.

-

Landscape & Urban Installations

- Shade Structures & Pavilions: Perforated panels form lightweight canopies for parks and plazas, such as the Serpentine Pavilion in London, where laser-cut aluminum provides dappled shade while enhancing airflow.

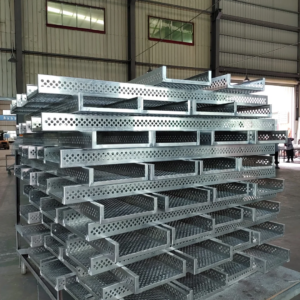

- Security & Privacy: Perforated fences and screens (3–10mm hole diameters) balance visibility and protection in urban spaces, like the perforated aluminum barriers at the Sydney Opera House forecourt, which deter vandalism without compromising views.

-

Sustainable Urban Solutions

- Green Infrastructure Integration: Panels support vertical gardens and photovoltaic systems, as seen in Singapore’s “Supertrees,” where perforated aluminum frames host air plants and solar panels, merging sustainability with sculptural design.

- Acoustic Mitigation: In transit hubs or highways, perforated panels paired with sound-absorbing backing reduce noise pollution, meeting standards like EN 1793-1 for traffic noise control.

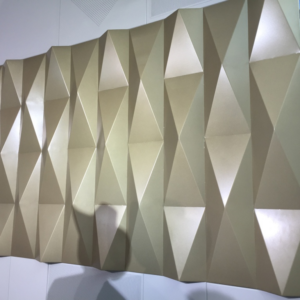

- Advanced Manufacturing: CNC punching and laser cutting achieve micron-level precision for complex patterns, while roll-forming creates curved or corrugated profiles (e.g., 50mm wave height) for dynamic textures.

- Modular Systems: Clip-and-lock installations simplify on-site assembly, reducing labor costs by 20–30% compared to traditional cladding materials.

- Weather-Resistant Finishes: Anodized coatings (25μm thickness) or fluorocarbon paints ensure colorfastness, with RAL color matching available for seamless integration with architectural palettes.

The Edge, dubbed the “world’s most sustainable office building,” utilizes aluminum perforated panels for its adaptive facade. Panels with variable perforation density adjust sunlight entry based on occupancy sensors, optimizing natural light while reducing energy use by 70%. The panels’ marine-grade 5052 alloy resists Amsterdam’s humid climate, exemplifying how technical innovation drives both performance and aesthetics.

- Longevity: Minimal maintenance and resistance to fading, rust, or warping.

- Design Freedom: Unlimited customization of hole size, pattern, and surface finish.

- Sustainability: 100% recyclable material with a low carbon footprint (85% less energy than steel production).

- Compliance: Meets global standards like ISO 9001, CE, and AS/NZS 1594 for structural integrity and weather performance.

As climate resilience becomes critical, aluminum perforated panels are evolving to include:

- Adaptive Systems: Integration with sensors to adjust perforation openness for real-time ventilation or solar control.

- Bio-Inspired Design: Mimicking natural patterns (e.g., fractals or fish scales) for enhanced aerodynamics and self-cleaning properties.

- Circular Economy Models: Use of recycled aluminum (up to 95% post-consumer content) in panel production.

Aluminum perforated panels have transcended mere building materials to become symbols of outdoor design ingenuity. Their ability to withstand harsh environments while enabling creative expression makes them indispensable for contemporary architects and urban planners. As cities prioritize sustainability and resilience, these panels will continue to shape the future of outdoor spaces—where functionality, beauty, and environmental responsibility coexist seamlessly.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!