Description

Aluminum Perforated Panels: Revolutionizing Architectural Design and Functionality

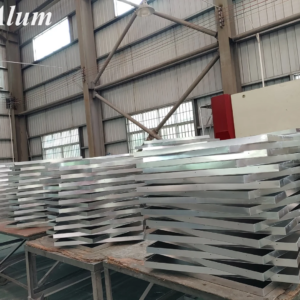

Aluminum perforated panels have emerged as a transformative material in modern architecture, blending aesthetic innovation with advanced functionality. These panels, crafted from high-quality aluminum alloys such as 3003, 5052, or 6061, feature precision-engineered perforations and versatile designs that redefine building facades, interiors, and industrial spaces.

- Alloy Selection:

Aluminum alloys like 3003 (corrosion-resistant), 5052 (marine-grade durability), and 6061 (high strength-to-weight ratio) are chosen based on application needs. These alloys ensure longevity, with salt spray test results exceeding 2,000 hours and resistance to extreme temperatures (-50°C to 80°C) .

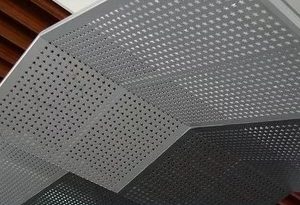

- Perforation Techniques:

CNC punching and laser cutting create intricate patterns (e.g., hexagonal, circular, or custom shapes) with precision. Laser-cut panels achieve clean edges and complex geometries, while CNC punching offers cost-effective mass production .

- Surface Finishes:

Anodizing and powder coating enhance durability and aesthetics. Fluorocarbon (PVDF) coatings provide 25+ years of UV resistance, ensuring color retention and low maintenance .

-

Architectural Facades:

- Sustainable Design: Panels filter sunlight, reduce glare, and improve thermal insulation. For example, the Fudan University canteen uses perforated aluminum for energy-efficient natural lighting .

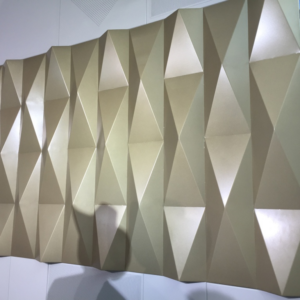

- Visual Impact: Wave-shaped panels (e.g., 120mm wave height) add dynamic texture, as seen in the Longhua Government parking facility’s facade .

-

Interior Spaces:

- Acoustic Control: Perforations combined with sound-absorbing materials (e.g., mineral wool) achieve Noise Reduction Coefficients (NRC) of 0.65–0.92, ideal for auditoriums and open offices .

- Decorative Elements: Laser-cut panels create artistic room dividers and ceiling installations, as showcased in Tokyo’s Shin-Marunouchi Building .

-

Industrial and Outdoor Use:

- Ventilation Systems: Panels with 15–30% perforation rates optimize airflow in factories and data centers .

- Safety Barriers: Perforated screens protect machinery while maintaining visibility .

- Lightweight and Durable:

Aluminum’s low density (1/3 of steel) reduces structural load, while its corrosion resistance eliminates rust concerns .

- Design Flexibility:

Customizable wave profiles, perforation patterns, and colors (e.g., matte blacks, metallic finishes) cater to diverse architectural visions .

- Sustainability:

Recyclable aluminum (95% recovery rate) and energy-efficient production align with green building certifications like LEED .

- Cost-Effective:

Lower installation costs (due to lightweight) and minimal maintenance offset initial expenses .

- Dynamic Systems:

Integrating smart materials (e.g., PET wind-driven panels) allows adaptive airflow and energy savings .

- Acoustic Solutions:

Aluminum honeycomb cores with perforated faces achieve high sound absorption, making them ideal for concert halls .

Aluminum perforated panels comply with global standards like ISO 10630 and GB/T 19360-2003, ensuring quality and safety . Future developments focus on eco-friendly coatings, modular designs, and AI-driven perforation patterns for personalized aesthetics.

Conclusion:

Aluminum perforated panels exemplify the fusion of form and function. Their lightweight durability, design versatility, and sustainability make them indispensable in contemporary architecture, driving innovation in both urban and industrial landscapes.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!