Description

Product Description

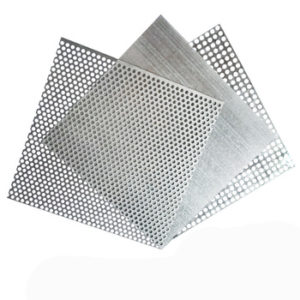

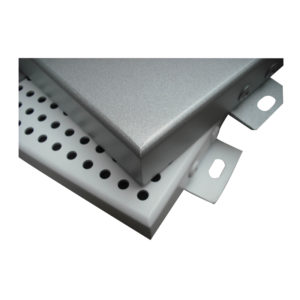

| Product Name | Outdoor Architecture Aluminum Perforated Facade Panels |

| Material | Aluminum Alloy AA3003H24 |

| Thickness | 0.8mm, 1.0mm, 1.5MM, 2.0mm, 2.5mm, 3.0mm |

| Width | 300/450/600/900/1100/1200/1220/2400/2440mm |

| Length | <6000mm |

| Surface Finishing | Powder coating,PE coating,PVDF coating,Anodizing,Shot-blasting |

| Color | RAL color,Wood Imitate,Stone Imitate,Mirror,brushed brass |

| Other Remarks | Can be customize |

Our Advantages:

1. We have a group of professional engineers, most of whom has more than 10 years’ experiences in architecture field.

2. Established for more than ten years, our company has got a various of experiences in design, manufacture, installation and so on. The work staffs have excellent skills. Some of them had helped customers to install the warehouse around the world.

3. We also have possessed more than 80 sets of large precise and domestically advanced processing equipments, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, slitters, shot blasting machines and so on.

4. Besides manufacture according to customers’ requirements, we also established a set of production standards. With perfect technique, excellent quality, reasonable price, top-grade services, we have won the favor of lots of customers at home and abroad.

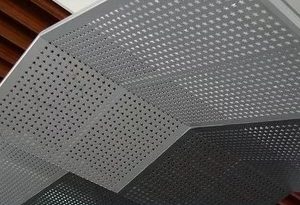

How is aluminum perforated panels made?

The manufacturing process for aluminum perforated paneling starts with sheet metal. Sheet metal is thin flat, and can be cut and bent into different shapes. In many area of the world, sheet metal thickness is measured in millimeters.

The most common method of perforating metal uses a rotary pinned perforation roller. This is a large cylinder with sharp, pointed needles on the outside to punch holes into the metal. As the sheet metal is run across the perforation roller, it rotates, continuously punching holes in the passing sheet.

Another common method is “die and punch” perforating. During this process, a sheet with needles is repeatedly pressed onto the passing metal which punches holes into the sheet. The pieces remaining from the punching are then sheared off and the surface is smoothed. The die and punch method are very efficient and can perforate a large surface of sheet very quickly.

Aluminum plate trim is made of high-strength aluminum alloy and fluorocarbon (PVDF) coating for excellent fire resistance.

Product packaging:

Packing Details:

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request.

3. Excellent in weather fastness and corrosion resistance.

4. Good fireproof and waterproof property.

5. Even coating, various colors.

6.Easy to process ,easy to maintain.

The container shipping:

Punching Sheet Hole:

Rectangular hole , Square hole , Diamond hole , Hole , Hexagonal hole , Cross hole , Triangle hole , Long hole , Along waist hole , Plum blossom hole , Scale hole , Hole Pattern , Star shaped holes , Irregular holes ,Drum hole etc,

Surface Treatment Process:

Skim →Alkali-Corrosion → Blare-elimination(by acid) →Chromiumizing → Drying → Parts-installation →Spraying Solidifying → Parts- removing → QC& Packing

Fabrication Process:

Sheet Metal Cutting- CNC Cutting(Punching,Laser Cutting-Hollow out)- Bending- Welding-Bracket Fixing-Polishing-Surface Treatment- QC-Package

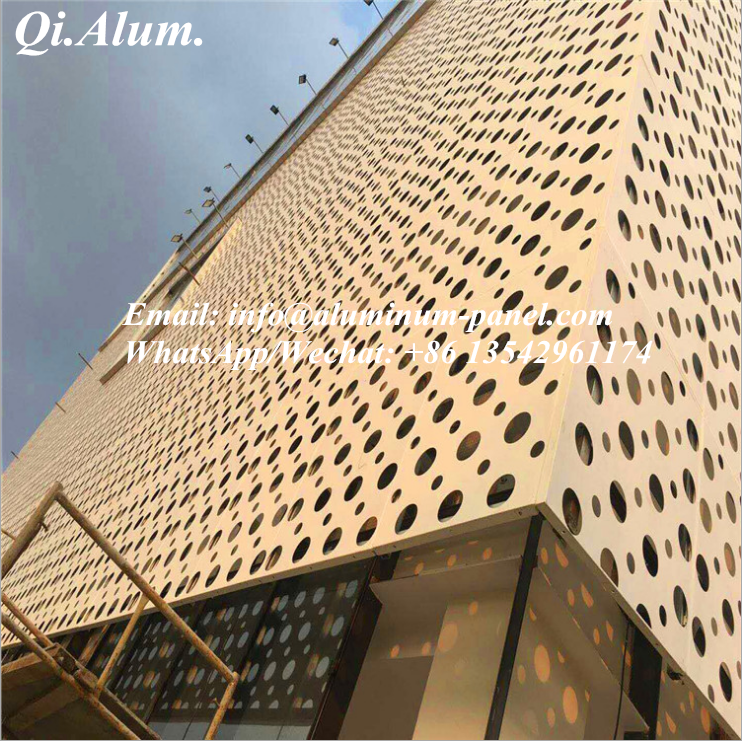

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence :

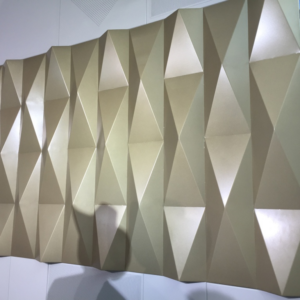

Decorative Living Room, Hotel, Bar, etc.

Indoor and outdoor public space backdrop, Elevator cabin, handrail,living room, background wall, ceiling, Kitchen equipment.

Specially for bar,club,KTV,hotel,bath center,villa,shopping mall

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

Projects list:

| FAQ Q: How long can I get a quote? A: The quotation can be provided no longer than 24 hours on condition that we know all detailed requirements. Q: Can I get samples? A: Free sample can be offered. Delivery can be arranged within 48 hours.

A: 15~25 day workdays .

Q: What’re your company’s main products? |

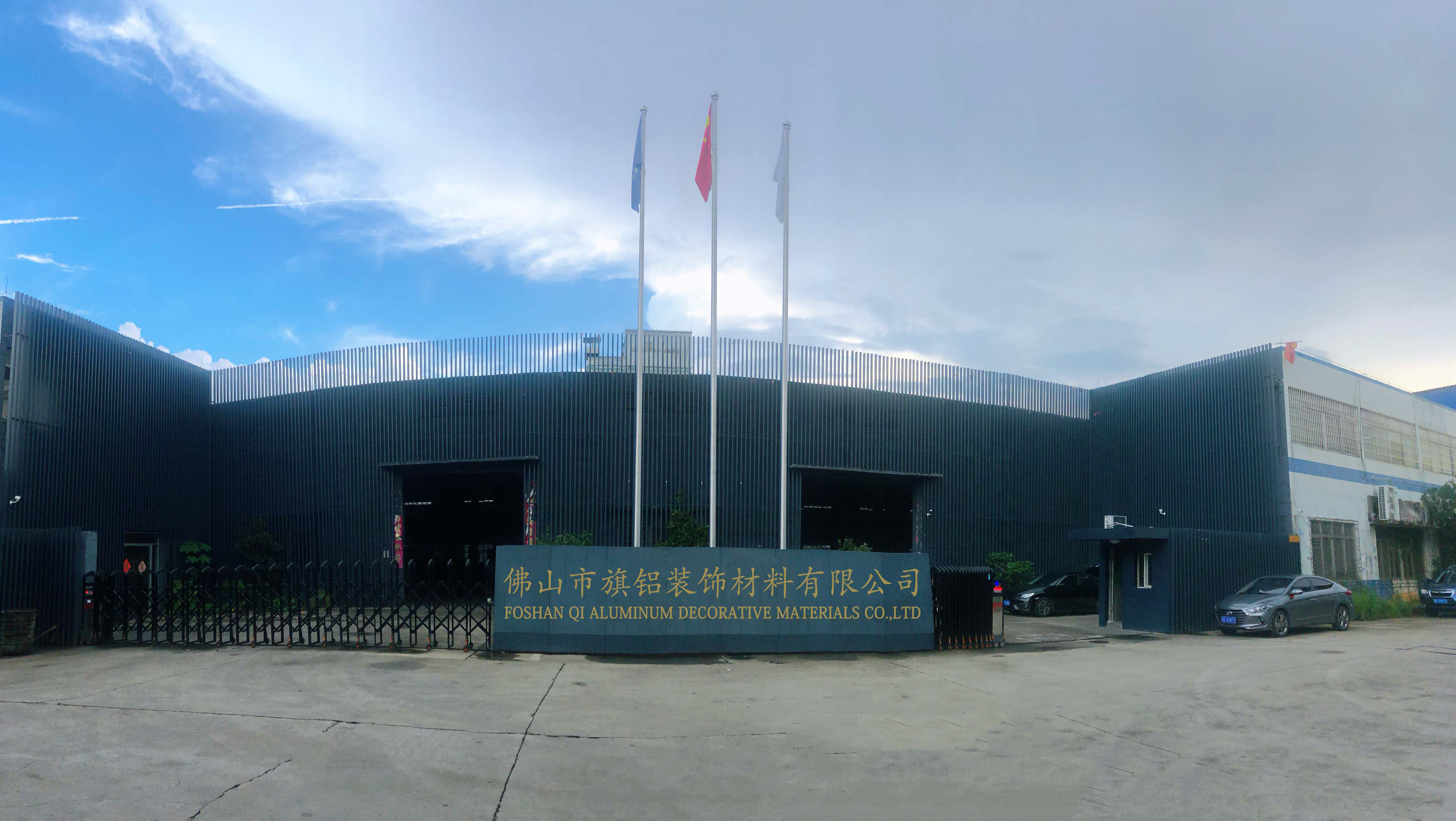

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!