The wall decoration board is a new type of building exterior wall decoration and insulation material developed in recent years. The material is made of polyester paint or fluorocarbon paint, carved aluminum zinc alloy steel plate, polyurethane insulation layer, glass fiber cloth. It is mainly used in gymnasium. Library, school and hospital office building, villa and other building exterior decoration and energy-saving renovation; main functions for architectural decoration, heat preservation and energy conservation, insulation and sound insulation, waterproof and mildew proof.

The metal surface decorative insulation board is a large format external mounted wall board produced in industrial production. The dry installation construction has good durability, low maintenance cost, and integrates exterior wall insulation and decoration functions, which is in line with the development direction of building energy conservation “modularization” technology. It is an advanced technology which is popularized vigorously in the field of exterior insulation technology of building wall in our country at present.

Main features:

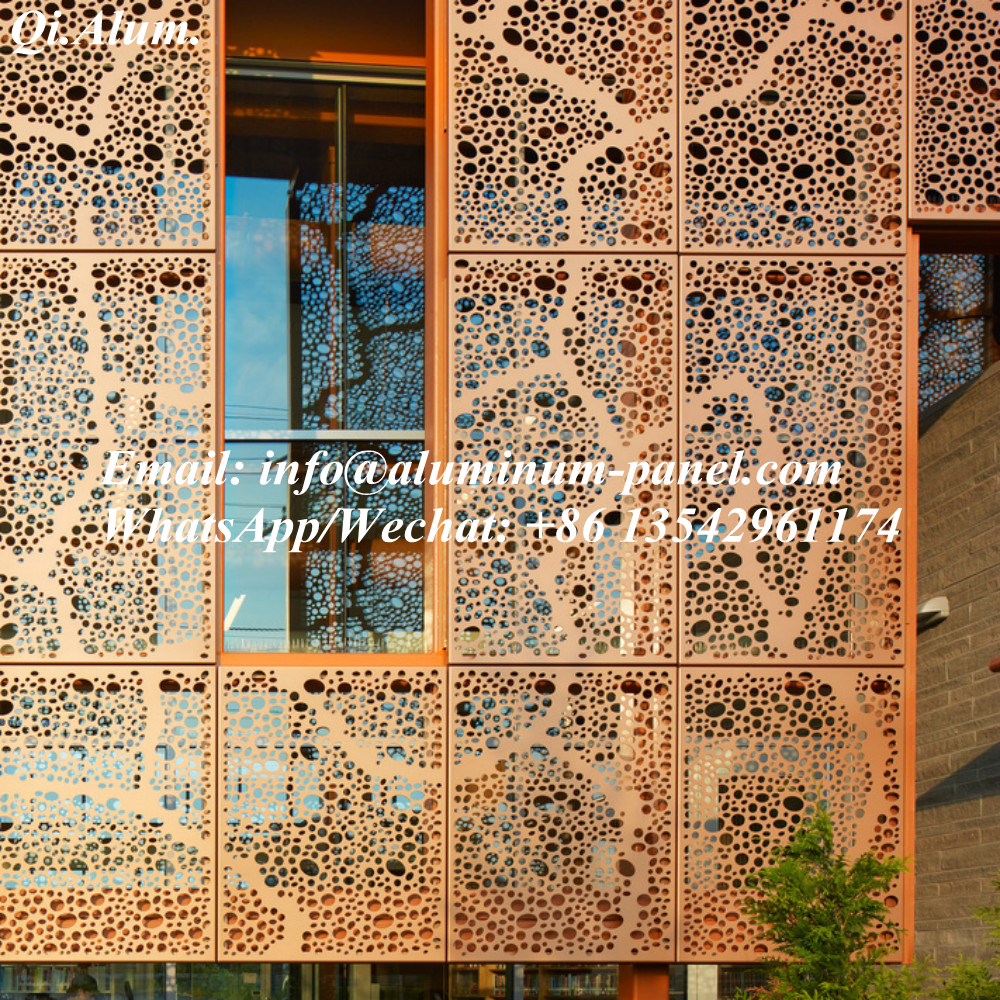

1, beautiful decoration: outer metal panel, through embossing, baking lacquer technology, can be made into marble, tile, mosaic, wood and other artistic appearance of 110 colors and textures can be selected.

2, heat preservation and energy saving: the inner layer insulation material is rigid foamed polyurethane, the thermal conductivity is less than 0.024 W / m ~ (k), the thermal insulation performance is better than XPS extruded plastic board and EPS polystyrene board.

3, easy construction: adopt keel dry hanging and wall connection, the product has lower requirement for flatness or humidity of the base course, no adhesive or hook joint is needed between board and board, and the temperature requirement is lower during construction, so it can be applied in winter; Because it has the function of decoration and heat preservation, it can ensure the construction of building decoration and heat preservation synchronously, which is conducive to shortening the construction period, speeding up the progress of the project and saving the construction cost.

4, durable: polyester topcoat, Coating on aluminum-zinc alloy steel surface by baking paint process, outdoor use for 10-15 years will not fade. The service life of aluminum-zinc alloy steel plate is more than 45 years.

5, environmental protection: this material uses environmental protection raw materials, assembly line production, finished product installation, construction and use process will not harm the environment, and can be recycled.