Description

Aluminum Assembly Panels: A Comprehensive Guide to Modern Building Solutions

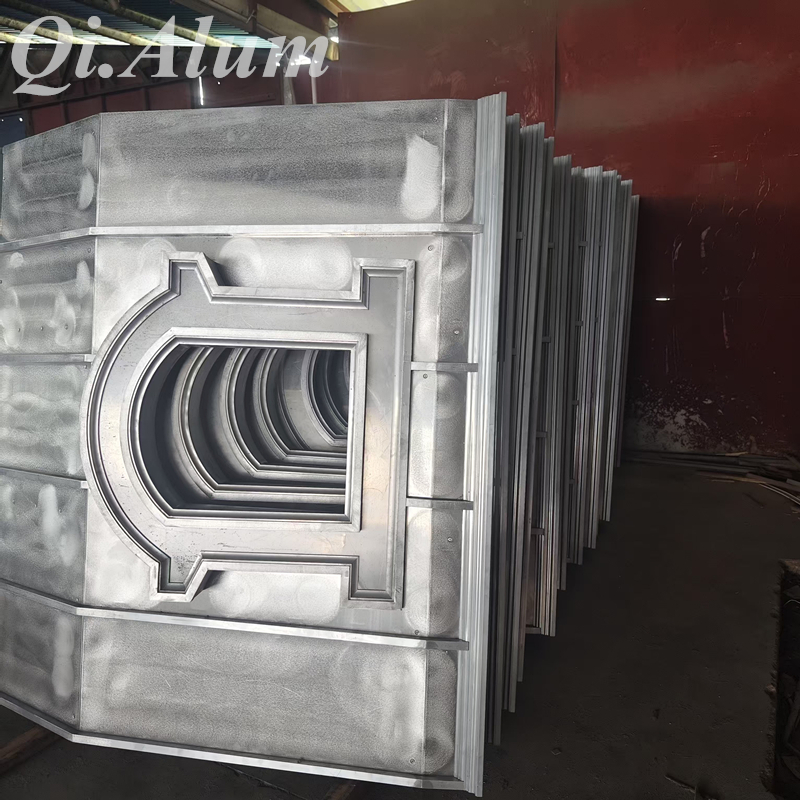

Introduction

In the realm of modern construction and industrial design, aluminum assembly panels have emerged as a versatile and sustainable material choice. Combining lightweight properties, durability, and adaptability, these panels are revolutionizing applications ranging from architectural cladding to modular furniture. This article explores the key features, benefits, and applications of aluminum assembly panels in today’s engineering landscape.

1. What Are Aluminum Assembly Panels?

Aluminum assembly panels are prefabricated components made from high-grade aluminum alloys, designed for easy integration into structural or decorative systems. They are often manufactured through extrusion or roll-forming processes, enabling precise shapes and interlocking mechanisms that simplify on-site installation.

Key Characteristics:

-

Lightweight Strength: Aluminum’s high strength-to-weight ratio ensures structural integrity without compromising portability.

-

Corrosion Resistance: Natural oxide layers and coatings (e.g., anodized or powder-coated finishes) enhance longevity in harsh environments.

-

Thermal and Electrical Conductivity: Ideal for applications requiring heat dissipation or electromagnetic shielding.

-

Recyclability: Aluminum is 100% recyclable, aligning with circular economy principles.

2. Manufacturing and Design Flexibility

Modern fabrication techniques allow aluminum panels to be tailored to diverse specifications:

-

Custom Shapes: CNC machining and extrusion enable complex geometries.

-

Surface Finishes: Options include brushed, polished, or textured surfaces for aesthetic versatility.

-

Modular Systems: Panels often feature interlocking edges or pre-drilled holes for rapid assembly, reducing labor costs.

3. Applications Across Industries

-

Architecture & Construction:

-

Facade cladding for energy-efficient buildings.

-

Retrofitting projects due to lightweight installation.

-

Interior partitions and suspended ceilings.

-

-

Transportation:

-

Lightweight panels for aerospace, automotive, and railcar interiors.

-

-

Industrial Equipment:

-

Machinery housings, control panels, and modular workstations.

-

-

Consumer Goods:

-

Furniture, display systems, and DIY kits.

-

4. Advantages Over Traditional Materials

-

Cost-Efficiency: Reduced transportation and installation costs compared to steel or concrete.

-

Sustainability: Lower carbon footprint during production and end-of-life recycling.

-

Low Maintenance: Resistant to rust, UV degradation, and pests.

5. Challenges and Considerations

-

Thermal Expansion: Proper joint design is critical to accommodate temperature fluctuations.

-

Initial Cost: While long-term savings are significant, upfront material costs may exceed plastics or wood.

6. Future Trends

Innovations in composite aluminum panels (e.g., aluminum honeycomb cores) and smart coatings (self-cleaning or photovoltaic-integrated surfaces) are expanding their potential. Additionally, digital tools like BIM (Building Information Modeling) are streamlining panel integration into sustainable designs.

Conclusion

Aluminum assembly panels represent a synergy of functionality and eco-conscious engineering. As industries prioritize efficiency and sustainability, their adoption is poised to grow, driven by advancements in manufacturing and material science. Whether for skyscrapers or portable devices, these panels offer a blueprint for the future of modular design.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!