Description

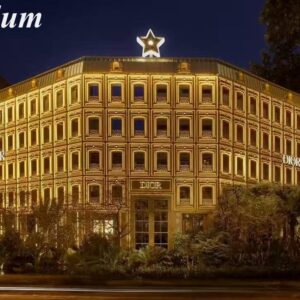

Precision Craftsmanship: Aluminum Assembly Panels Transform Dior Thailand’s Architectural Vision

A Fusion of Luxury and Engineering Excellence

The Project Blueprint: Dior’s Demanding Standards

- Architectural Grandeur: A seamless, reflective surface to echo Dior’s sophisticated aesthetic

- Climate Resilience: Resistance to humidity, UV radiation, and corrosion

- Time Efficiency: A tight 3-month timeline from design to grand opening

Why Aluminum Assembly Panels? Three Core Advantages

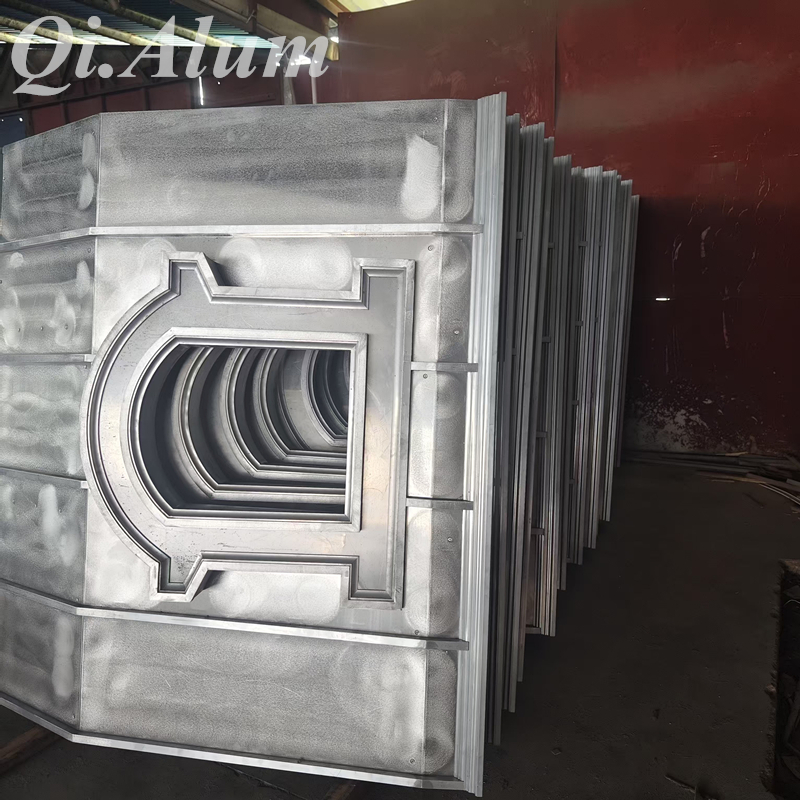

1. Design Flexibility for Iconic Aesthetics

- Parametric Precision: CNC-machined panels achieved complex curves and seamless joints, creating a “floating” facade effect

- Luxury Finishes: Anodized and mirror-polished coatings replicated Dior’s signature metallic sheen, with dual-layer PVDF treatments for long-term luster

2. Tropical Climate Engineering

- Corrosion Resistance: 3003-series aluminum alloys with anti-oxidation treatments defied Bangkok’s high humidity

- UV Stability: Specialized coatings prevented color fading, maintaining the facade’s vibrant reflection over time

3. Rapid Modular Deployment

- Prefabricated Efficiency: 850+ panels were pre-assembled in a controlled factory environment, reducing on-site installation to just 15 days

- Lightweight Structure: Panels weighing 60% less than traditional cladding materials minimized structural load and installation complexity

The Execution Journey: From Concept to Completion

Phase 1: Collaborative Design Engineering

- Worked with Dior’s Parisian design team to translate sketches into 3D parametric models

- Optimized panel sizes to eliminate visible seams, achieving a monolithic aesthetic

Phase 2: Manufacturing Mastery

- Employed robotic cutting systems for millimeter-level precision

- Implemented a rigorous 5-stage quality control process, including salt spray testing for corrosion resistance

Phase 3: Surgical Installation

- Deployed a specialized crew trained in hidden-fastening techniques

- Integrated weatherproof seals during installation to ensure long-term durability

The Result: A Landmark in Luxury Retail Architecture

- Time Savings: Completed 3 weeks ahead of schedule, enabling Dior to host a VIP launch event as planned

- Visual Impact: The facade’s dynamic light reflection has become a social media hotspot, generating organic brand exposure

- Sustainability Credentials: 100% recyclable aluminum panels aligned with Dior’s global eco-initiatives

Redefining Possibilities for Luxury Projects

- Uncompromising aesthetic fidelity to brand identities

- Engineered resilience in challenging climates

- Rapid deployment without sacrificing quality

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!