Description

Double-Curved Aluminum Panels: The Future of Architectural Innovation

In the ever-evolving world of architecture and construction, double-curved aluminum panels have emerged as a game-changing material, combining aesthetic versatility with unmatched structural performance. As a leading supplier of advanced building solutions, [Your Company Name] is proud to offer precision-engineered double-curved aluminum panels designed to transform bold visions into reality. This article explores their benefits, applications, technical specifications, and why they are the top choice for modern projects.

1. What Are Double-Curved Aluminum Panels?

Double-curved aluminum panels are single-layer aluminum sheets molded into complex, three-dimensional shapes with curvature along two axes. Unlike flat or single-curved panels, these sheets can form organic geometries such as spheres, waves, or free-flowing designs, making them ideal for creating visually striking architectural elements.

Key Features:

- Material: High-grade aluminum alloys (3003, 5052, or 6061).

- Thickness: 1.5–6 mm (customizable for load requirements).

- Surface Finishes: PVDF coating, anodized, powder-coated, or mirror-polished.

- Sustainability: 100% recyclable and energy-efficient.

2. Why Choose Double-Curved Aluminum Panels?

2.1 Unmatched Design Flexibility

Architects and designers are no longer constrained by flat surfaces. Double-curved panels enable:

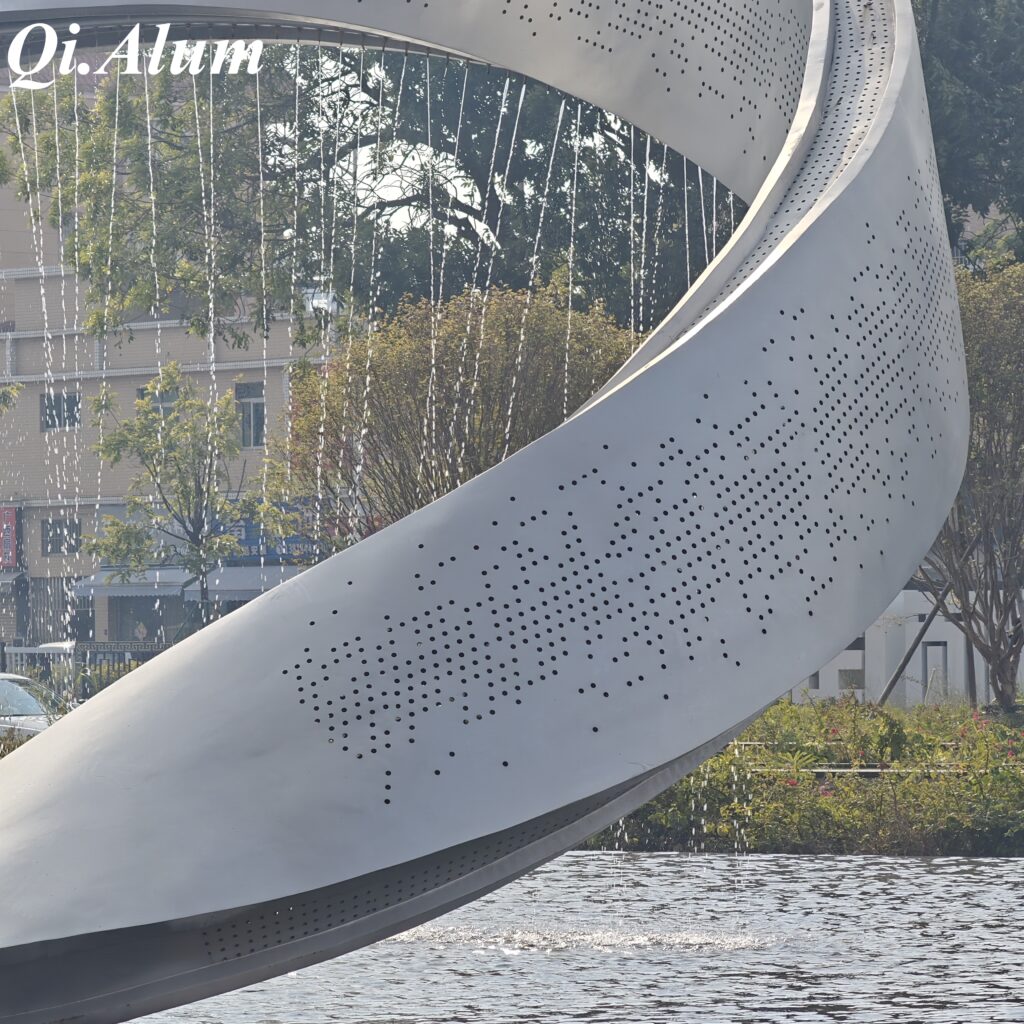

- Organic Shapes: Create fluid facades, domes, or sculptural installations.

- Custom Patterns: Perforations, embossing, or digital prints for unique textures.

- Seamless Integration: Blend with glass, steel, or wood for hybrid designs.

2.2 Superior Durability

- Weather Resistance: Withstand UV rays, heavy rain, and extreme temperatures (-30°C to 80°C).

- Corrosion Protection: Ideal for coastal or industrial environments (marine-grade options available).

- Fire Safety: A2 fire-rated (non-combustible) for compliance with global building codes.

2.3 Cost and Time Efficiency

- Lightweight Design: Reduces structural support costs.

- Prefabrication: CNC-machined panels ensure quick on-site assembly.

- Low Maintenance: Resists dirt accumulation and requires minimal cleaning.

3. Technical Specifications

| Parameter | Details |

|---|---|

| Material | 3003/5052/6061 aluminum alloy (ASTM B209 standard) |

| Thickness | 1.5–6 mm (customizable) |

| Panel Size | Up to 6,000 mm × 2,000 mm (larger sizes upon request) |

| Surface Coating | PVDF (AAMA 2605), powder coating (AAMA 2604), or anodized (AA-M12C22A41) |

| Curvature Radius | 50 mm to 5,000 mm (CNC precision) |

| Certifications | ISO 9001, EN 1396, LEED/BREEAM compliance |

4. Top Applications of Double-Curved Aluminum Panels

4.1 Iconic Building Facades

From skyscrapers to museums, double-curved panels redefine urban skylines.

- Example: The undulating facade of the Heydar Aliyev Center (Baku) showcases the material’s ability to mimic natural forms.

4.2 Roofing & Canopies

- Stadiums: Aerodynamic designs enhance airflow and aesthetics.

- Airports: Lightweight panels reduce roof load while ensuring durability.

4.3 Interior Design

- Ceilings: 3D wave panels add depth to lobbies or auditoriums.

- Partitions: Curved dividers create dynamic office layouts.

4.4 Public Art & Landmarks

- Sculptures: Weather-resistant panels for outdoor installations.

- Signage: Eye-catching curved logos for branding.

5. Installation and Maintenance

5.1 Precision Installation

- Prefabricated Kits: Panels arrive numbered for foolproof assembly.

- Mounting Systems: Hidden clips or rail systems ensure seamless joints.

5.2 Maintenance Tips

- Cleaning: Use mild soap and water; avoid abrasive tools.

- Inspection: Check for dents or coating wear annually.

6. Sustainability & Green Building Compliance

- Recyclability: Aluminum retains 95% of its properties after recycling.

- Energy Efficiency: Reflective coatings reduce cooling costs by up to 20%.

Frequently Asked Questions (FAQ)

Q1: How long is the lead time for custom panels?

A: Standard orders: 15–30 days. Rush orders: 10 days (surcharge applies).

Q2: Can panels be repaired if damaged?

A: Minor dents can be field-repaired; severe damage requires panel replacement.

Q3: Are curved panels more expensive than flat ones?

A: Initial costs are higher, but savings in installation and maintenance offset the difference.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!