Description

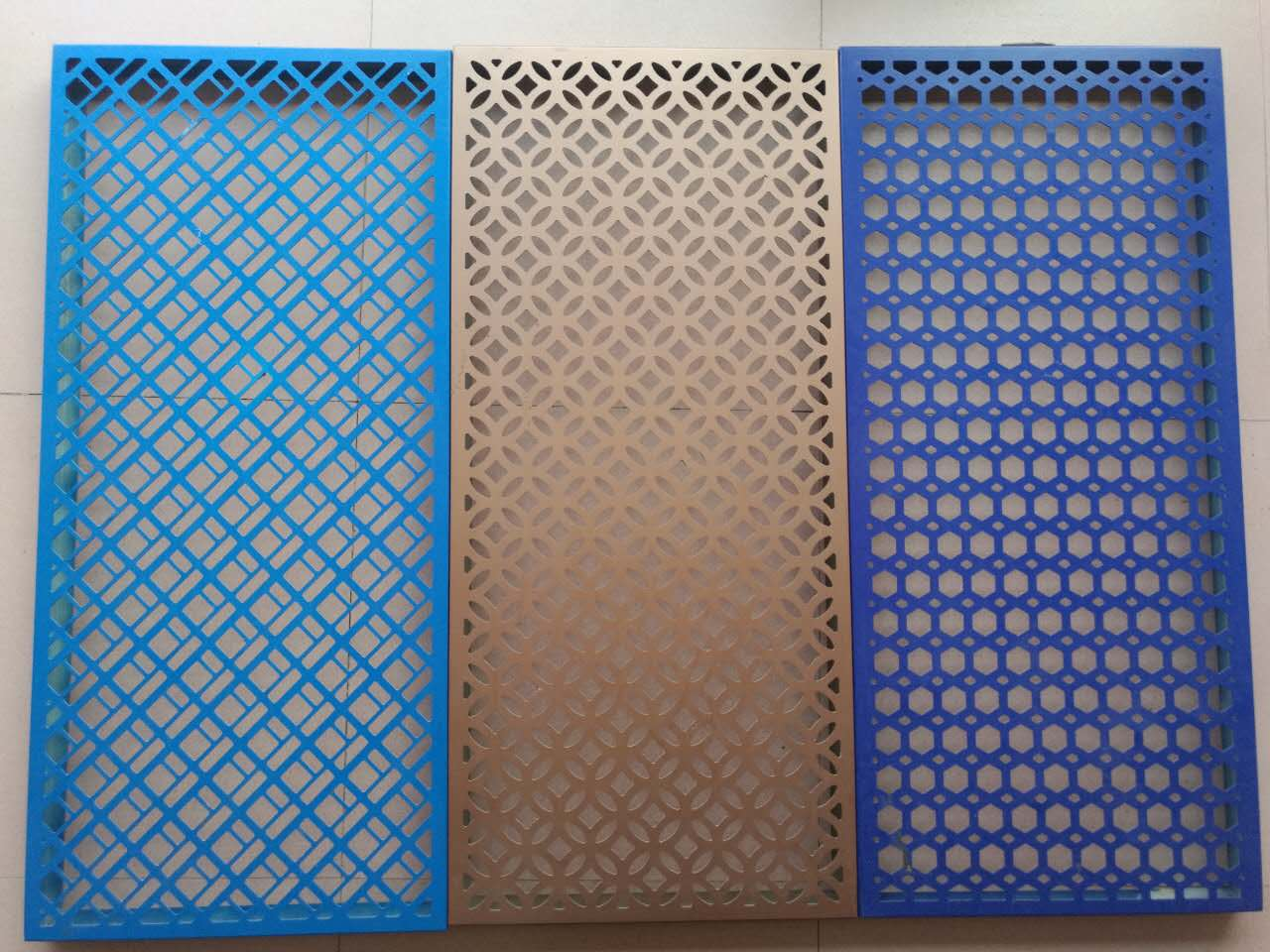

Aluminum Cladding panel for Interior Decoration

Product Description

| Surface Coating | PE coating, Primer Coating ,Mill finish |

| Aluminum Alloy | AA1100, AA3003 |

| Aluminum Skin | 0.10mm,0.12mm,0.15mm,0.18mm,0.21mm,0.25mm,0.30mm |

| Panel Thickness | 2mm,3mm,4mm,5mm |

| Core Material | Non-toxic low density polyethylene |

| Panel Width | 1000mm,1220mm,1250mm,1500, |

| Panel Length | 2440mm,3050mm,4000mm,5000mm |

Advantage

It is in light weight, good rigidity, and high strength;

It has good weathering resistance;

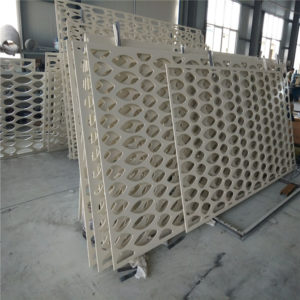

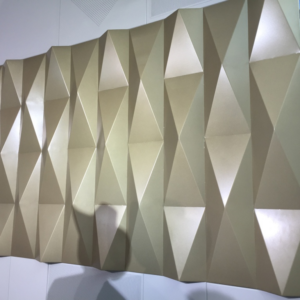

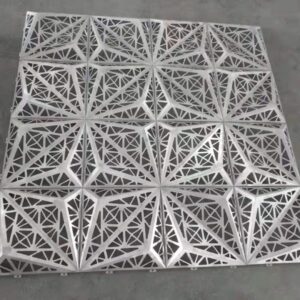

It is easy to process and weld, can be processed complex shape such as flat panel, curve panel, twist panel, etc.

It has many colors to choose to make good embellishing effects.

It has good stain resistance, it is easy to clean and maintain; easy to assemble and can be recycled, conducive to environmental protection.

*Scopes of Application

1) Aluminum façade, Aluminum Cladding, Exterior Wall Decoration.

2) Interior Wall Decoration, Column cladding

3) Passageway, elevator, shopfront decoration, advertisement boards.

4) Ceiling and so on.

5) With complicated shape such as pagoda, difficult to get dirt, easy for maintenance and caring.;

6) Wide color selection, ultra good decoration effect;

7) Easy to be recycled, with no pollution, good for sustainable development and saving the earth.

Production process of aluminum panel

01. Project design → 02. Cellular drawing → 03. Word out procedures → 04. Plate check → 05. Plate banking → 06. Contour and punch → 07. Pressure bend → 08. Abnormal shape machining → 09. Angling & sealing weld → 10. Rim angle trimming & loader installation → 11. Stud welding reinforcement → 12. Surface polish → 13. Drug test → 14. Clean & chromium → 15. Electrostatic spray → 16. Quality inspection → 17. Film pasting & packing