Description

Outdoor Aluminum Air Conditioning Covers: Engineered for Protection, Style, and Longevity

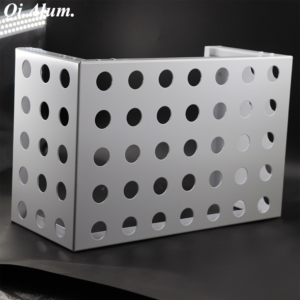

In the realm of modern architecture, outdoor aluminum air conditioning covers have evolved from functional necessities to architectural statements. Engineered to withstand the harshest environmental conditions while enhancing curb appeal, these covers blend premium materials, innovative design, and sustainable practices to redefine HVAC protection for residential, commercial, and industrial properties.

The Ultimate Solution for Outdoor HVAC Protection

1. Unmatched Durability Against the Elements

Crafted from high-grade aluminum alloys (3003-H24 for general use, 5052-H32 for marine environments), these covers feature:

- Weatherproof Construction: PVDF or powder-coated finishes tested to withstand 5,000+ hours of salt spray (ASTM B117) and 1,000+ hours of UV exposure (QUV), ideal for tropical climates, coastal areas, and extreme temperatures.

- Structural Rigor: 1.5–4.0mm thickness with reinforced edges that resist wind loads up to 150 mph (ASTM E330 certified) and impact from debris.

- Corrosion Resistance: Anodized treatments or anti-oxidation coatings prevent rust, ensuring 25+ years of maintenance-free performance.

2. Design Versatility for Architectural Harmony

- Customizable Aesthetics: Choose from 50+ RAL colors, brushed metallics, wood-grain textures, or custom prints to match building facades, such as bronze finishes for Mediterranean villas or sleek silver for modern high-rises.

- Decorative Patterns: Perforated grids, slat designs, or laser-cut motifs (e.g., brand logos, geometric art) transform covers into design elements rather than utilitarian fixtures.

3. Energy Efficiency & Functional Innovation

- Thermal Regulation: Louvered or perforated panels (15–60% open area) maintain 100% airflow while reducing direct sunlight, lowering unit temperatures by 10–15°C and cutting energy consumption by 12%.

- Noise Reduction: Embossed or honeycomb structures absorb mechanical noise, creating quieter outdoor spaces (noise reduction up to 8dB).

- Integrated Features: Bird-proof mesh, anti-theft locks, and thermal break technology for condensation prevention.

Technical Excellence: Materials & Engineering

Premium Materials at Work

| Feature | Performance Data | Industry Advantage |

|---|---|---|

| Aluminum Alloy | 3003-H24 / 5052-H32 | Lightweight yet 3x stronger than steel |

| Surface Treatment | PVDF 3-layer coating | 25+ year fade resistance |

| Perforation Technology | Laser-cut holes (1–50mm diameter) | Precision airflow management |

| Fire Rating | A2-s1,d0 (compliant with EN 13501) | Suitable for high-rise buildings |

Innovative Installation Systems

- Modular Design: Snap-fit or boltless components with laser-etched mounting guides enable installation in <25 minutes with standard tools—40% faster than traditional systems.

- Hidden Fasteners: Seamless appearance with no visible screws, ideal for luxury properties.

- Retrofit Compatibility: Custom designs for existing HVAC units without demolition.

Applications Across Sectors

1. Residential Projects

- Balcony & Rooftop Units: Sleek covers for condos and apartments that protect against debris while enhancing balcony aesthetics.

- Single-Family Homes: Custom-colored covers matching siding or roofing, such as terracotta finishes for Spanish-style homes.

2. Commercial & Hospitality

- Hotels & Retail: Perforated covers with brand logos with lattice designs create iconic facades (e.g., luxury resorts in Phuket).

- Office Buildings: Heavy-duty covers on rooftop AC arrays with noise-reduction features for nearby windows.

3. Industrial & Public Infrastructure

- Data Centers & Factories: Corrosion-resistant covers in coastal areas (e.g., Singapore ports) protecting critical systems.

- Transportation Hubs: Airport AC units shielded by fire-retardant covers (ASTM E84 Class A compliant).

Case Study: Beachfront Resort in Pattaya

- Challenge: A 5-star resort needed AC covers that:

- Withstood year-round salt air and monsoons

- Matched the luxury oceanfront design

- Reduced noise for poolside guests

- Solution: 3mm 5052 marine-grade aluminum covers with:

- Ocean-blue PVDF coating (RAL 5015)

- 40% perforation for airflow

- Stainless steel fasteners

- Result: Installed on 200+ units, the covers withstood 8,000+ hours of salt spray testing, reduced noise by 10dB, and became a key selling point for the resort.

Sustainability: A Green Building Choice

- Recycled Content: Manufactured with 70–90% post-industrial recycled aluminum, cutting carbon footprints by 60% vs. steel covers.

- Circular Economy: 100% recyclable at end-of-life, with take-back programs available.

- Green Certifications: Contributes to LEED, BREEAM, and Thailand’s Green Building Index (TGBI).

Buyer’s Guide: Choosing the Right Outdoor Cover

- Measure Your Unit:

- Record height, width, depth (allow 5–10cm clearance for airflow).

- Climate Considerations:

- Coastal areas: Specify 5052 marine-grade aluminum.

- High-wind zones: Opt for welded frames (wind load ≥1.2 kN/m²).

- Design Priorities:

- Aesthetics: Perforated or slat patterns;

- Functionality: Lockable designs for security, insulated panels for noise.

Elevate Your Outdoor Space with Aluminum AC Covers

Outdoor aluminum air conditioning covers offer more than protection—they blend technical innovation with design excellence, transforming HVAC units into architectural assets. Whether for a beachfront villa, urban skyscraper, or industrial complex, these covers deliver long-term value in durability, efficiency, and style.

Contact us today for a custom quote, CAD drawings, or to explore our project gallery. Let’s collaborate to redefine how functional elements enhance your property’s design and performance.