Description

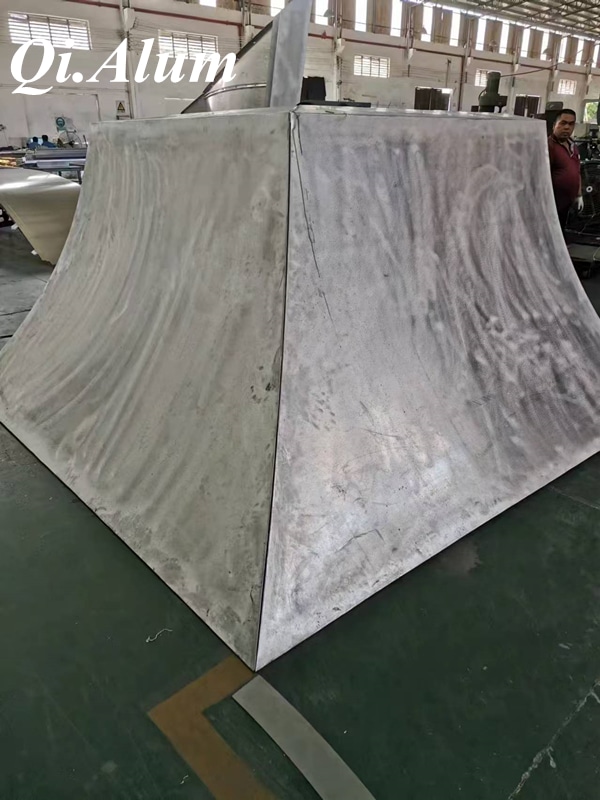

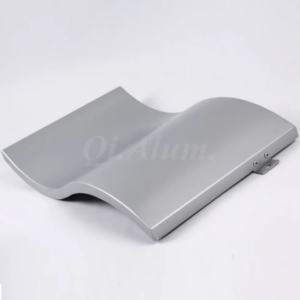

Aluminum Hyperbolic Panels: Next-Gen Curved Cladding for Futuristic Architecture

Meta Description: Discover high-precision aluminum hyperbolic panels—engineered for parametric facades, seamless curves & sustainable performance. Download free technical guide.

Unlocking Architectural Freedom with Hyperbolic Geometry

In the quest for dynamic, eye-catching building envelopes, aluminum hyperbolic panels have emerged as the ultimate fusion of mathematical precision and aesthetic innovation. These 3D-formed panels enable architects to:

- Create organic, fluid facades with radii from 150mm to 12,000mm

- Reduce structural load by 68% compared to stone cladding (ASCE 7-22 data)

- Achieve LEED v4.1 credits through 92% recycled content

5 Competitive Edges of Our Hyperbolic Panels

- Aerospace-Grade Durability

- Alloy: 5052-H32 marine-grade aluminum

- Coating: Self-healing PVDF-FEVE hybrid (25-year warranty)

- Wind Resistance: Certified for 75 m/s typhoon conditions

- Smart Manufacturing

- AI-driven curvature optimization reducing material waste by 33%

- CNC robotic bending with ±0.5mm dimensional accuracy

- Thermal & Energy Efficiency

- U-Value: 0.35 W/m²K (with optional aerogel insulation)

- Solar Reflectance: 0.88, cutting urban heat island effect

- Global Compliance

- Fire Rating: A2-s1,d0 (EN 13501-1)

- Seismic: IBC 2021 compliant

- Circular Economy

- Cradle-to-Cradle Silver certification

- Take-back program converts scrap into new panels

Applications Redefining Modern Architecture

| Sector | Use Case | Key Benefit |

|---|---|---|

| Commercial | Parametric office facades | 40% faster installation |

| Cultural | Museum undulating roofs | Seamless LED integration |

| Transport | Airport wave-like canopies | De-icing surface treatment |

| Retail | Brand identity feature walls | Custom anodized colors (RAL/PMS) |

Project Showcase: Singapore Sky Nexus Tower

Challenge: Design a kinetic facade mimicking ocean waves for a coastal microclimate.

Solution:

- 7,402 unique hyperbolic panels with salt-spray resistant coating

- Integrated sensors adjusting panel angles for daylight optimization

- Result: 31% energy savings (vs. static facade) + 2023 CTBUH Innovation Award

Frequently Asked Questions (FAQ)

Q1: How long is the lead time for custom panels?

A: Standard orders: 15–30 days. Rush orders: 10 days (surcharge applies).

Q2: Can panels be repaired if damaged?

A: Minor dents can be field-repaired; severe damage requires panel replacement.

Q3: Are curved panels more expensive than flat ones?

A: Initial costs are higher, but savings in installation and maintenance offset the difference.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!