Description

Aluminum Perforated Panels in Interior Design: Merging Aesthetics and Functionality

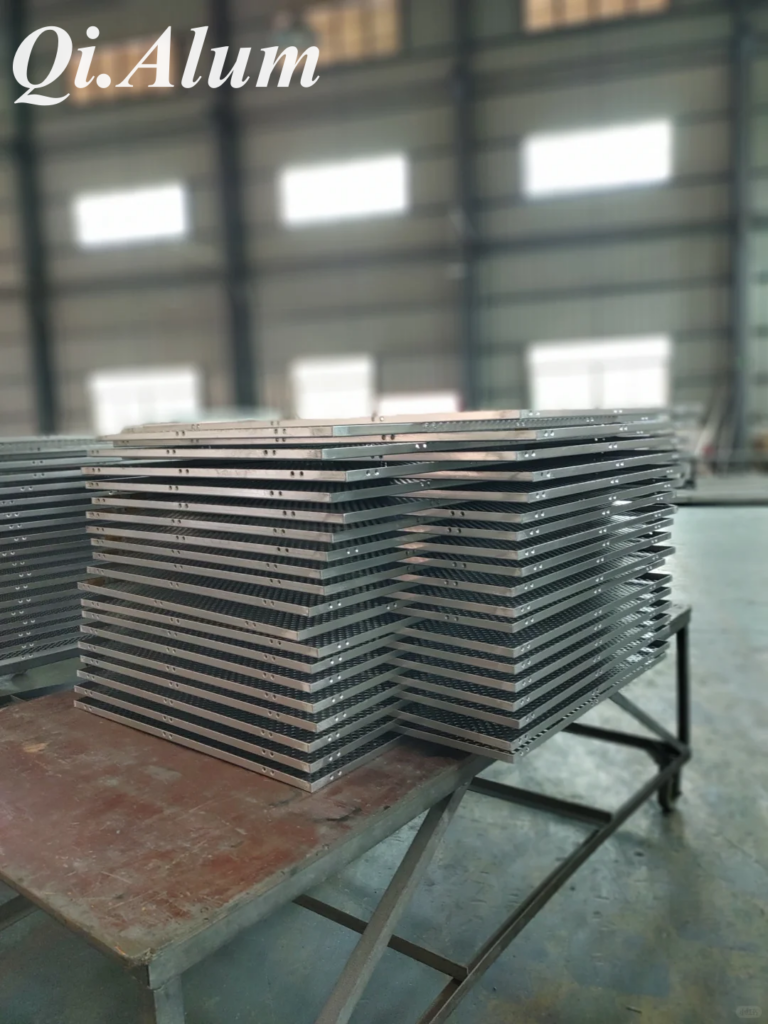

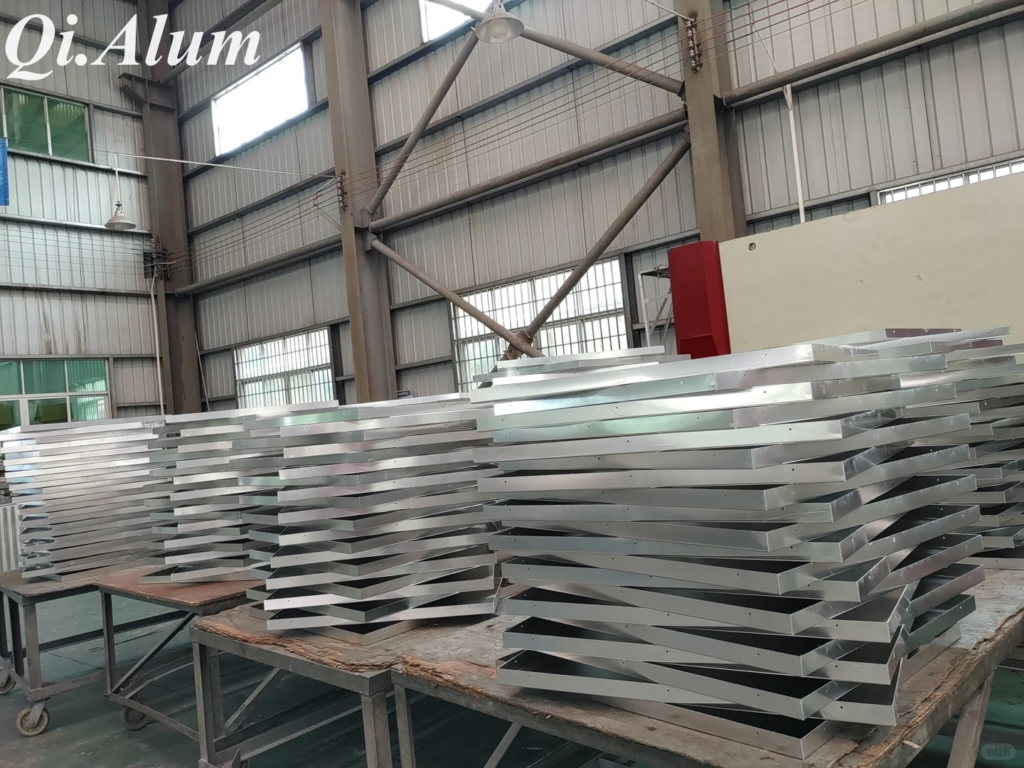

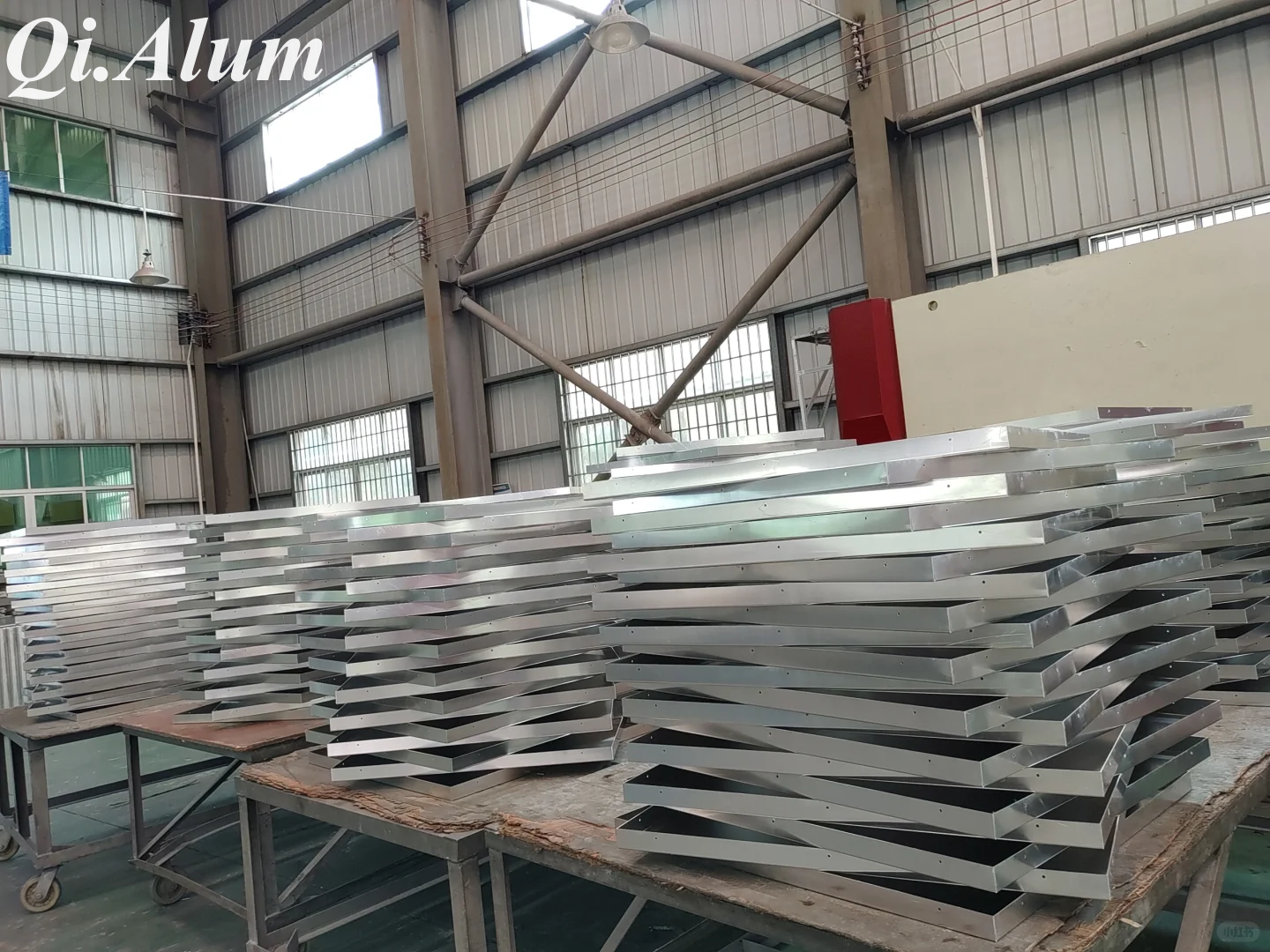

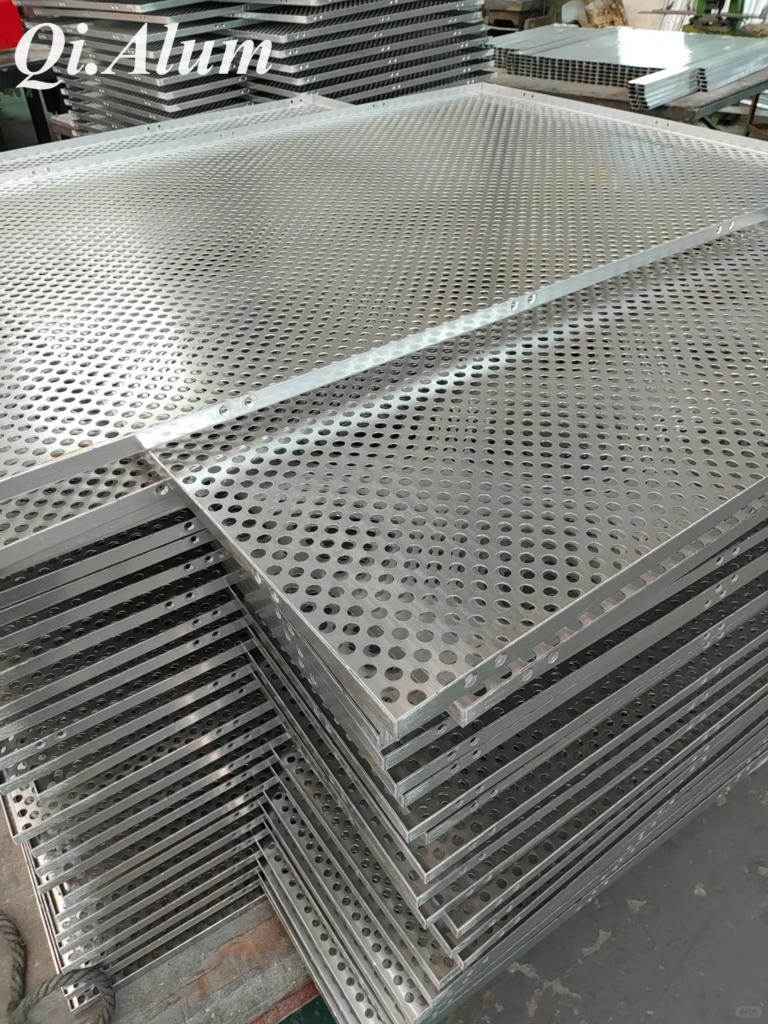

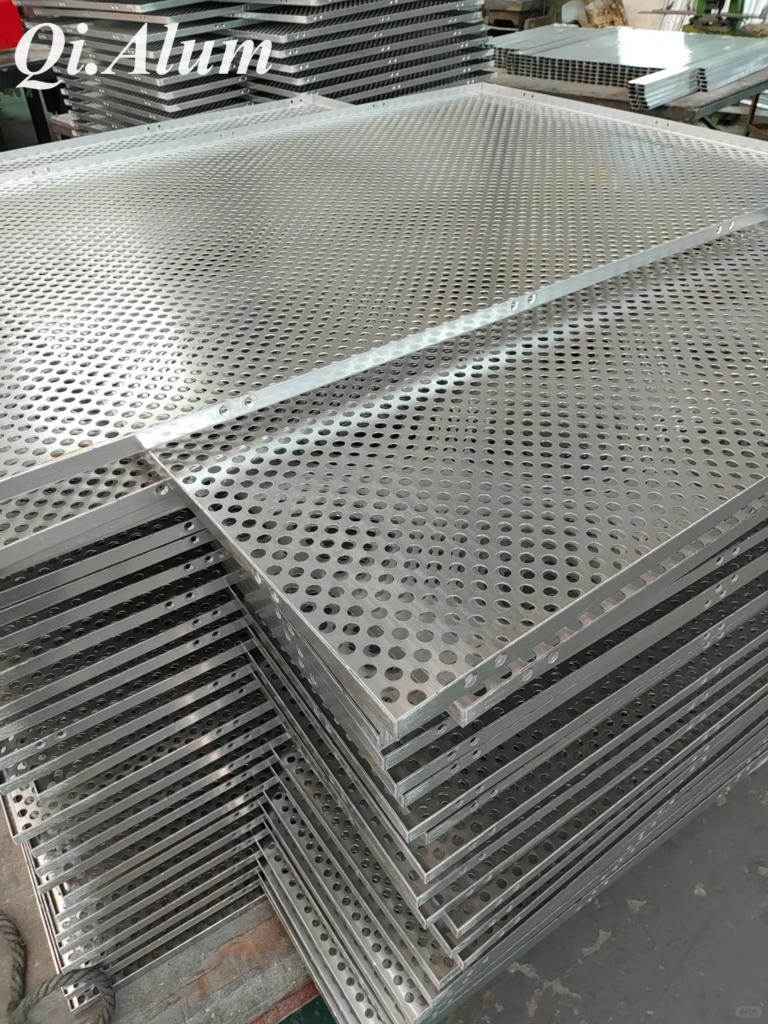

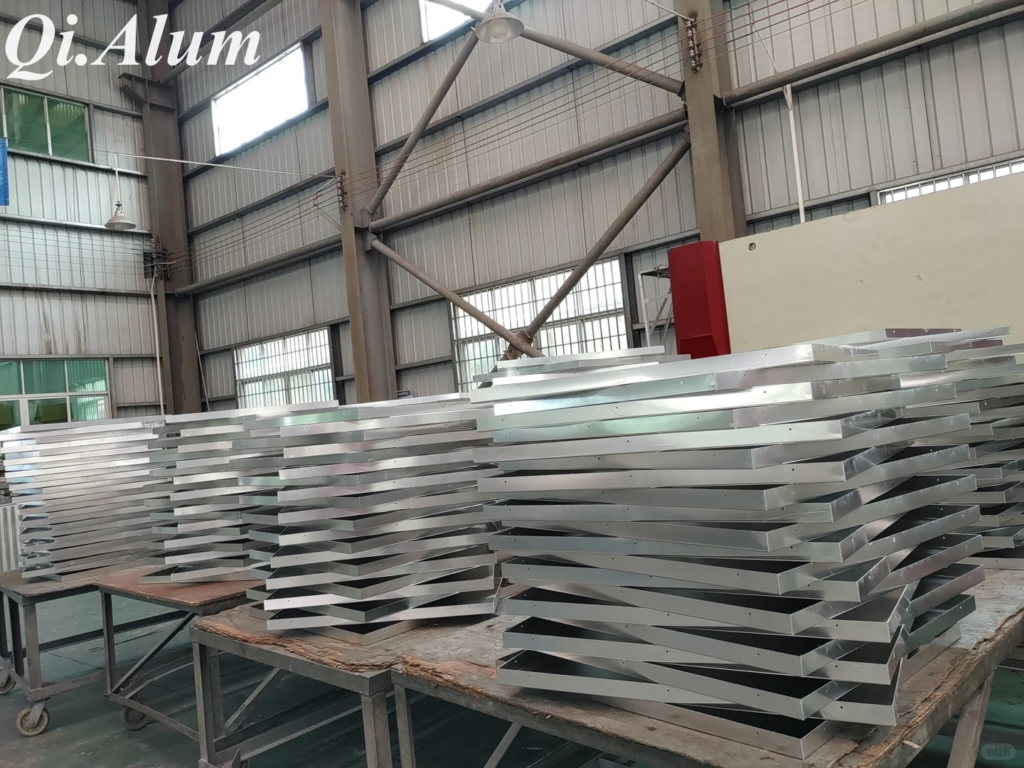

Aluminum perforated panels have emerged as a transformative material in modern interior design, offering unparalleled versatility in balancing visual appeal, acoustic performance, and sustainability. These panels, crafted from high-quality alloys like 3003, 5052, or 6061, feature precision-engineered perforations that redefine spatial experiences in residential, commercial, and institutional settings.

-

Acoustic Optimization

Perforated aluminum panels excel in noise reduction, with perforation patterns (e.g., circular, hexagonal) and backer materials (e.g., mineral wool or fiberglass) achieving Noise Reduction Coefficients (NRC) of 0.65–0.92 . For instance, micro-perforated panels like Silk Metal™ achieve an NRC of 0.80, making them ideal for auditoriums, open-plan offices, and healthcare facilities . The combination of perforations and sound-absorbing cores creates dynamic acoustic environments, reducing echoes and enhancing speech clarity.

-

Decorative and Spatial Enhancement

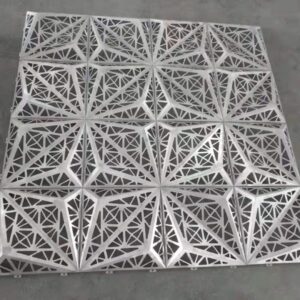

- Light and Shadow Play: Laser-cut patterns (e.g., geometric motifs, floral designs) cast intricate shadows, transforming interiors into living art. Tokyo’s Shin-Marunouchi Building uses perforated aluminum ceilings with cherry blossom patterns to create immersive, nature-inspired spaces .

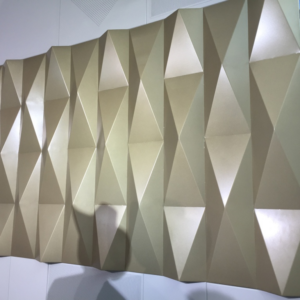

- Zoning and Privacy: Perforated screens (e.g., rusted metal in New Delhi stores or curved designs in Hong Kong retail spaces) define areas while maintaining visual continuity . Wave-shaped panels (120mm height) add texture to walls, as seen in the Longhua Government parking facility .

-

Functional Design Solutions

- Ventilation and Thermal Control: Panels with 15–30% perforation rates optimize airflow in data centers and factories, while their thermal insulation properties reduce energy consumption .

- Customizable Lighting: Perforations diffuse light evenly, eliminating glare. For example, serpentine chandeliers with laser-cut designs in Tokyo’s camping store create ambient, nature-inspired illumination .

- Durability: Aluminum alloys resist corrosion (e.g., 5052 marine-grade for humid environments) and extreme temperatures (-50°C to 80°C) .

- Sustainability: Recyclable (95% recovery rate) and energy-efficient, aligning with LEED and BREEAM certifications .

- Lightweight and Cost-Effective: Aluminum’s low density reduces structural load, while modular designs simplify installation and maintenance .

- Surface Finishes: Anodizing and PVDF coatings (25+ years of UV resistance) offer color stability and durability. Matte blacks, metallic hues, or wood-grain finishes cater to diverse styles .

- Structural Adaptability: CNC punching and laser cutting enable complex shapes (e.g., curved panels for auditoriums or honeycomb cores for sound absorption) .

- Commercial Spaces: A 4S shop in China uses curved perforated aluminum cladding to create dynamic facades, while a Cambodian office building employs triangular perforations for modernist aesthetics .

- Residential Projects: Perforated aluminum ceilings in luxury homes provide acoustic comfort, while kitchen cabinets with perforated doors blend industrial and rustic styles .

- Smart Integration: Embedded LED strips or photovoltaic cells transform panels into interactive media facades or energy-generating surfaces .

- Sustainable Practices: Low-carbon manufacturing and circular economy principles drive innovation in eco-friendly coatings and modular designs .

Conclusion

Aluminum perforated panels redefine interior design by merging form and function. Their ability to enhance acoustics, manipulate light, and adapt to diverse aesthetics makes them indispensable in contemporary architecture. As demand for sustainable and technologically advanced materials grows, these panels will continue to shape the future of spatial design.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!