Description

Aluminum double-curved panels are a revolutionary material in modern architecture and design, offering both aesthetic appeal and functional benefits. These panels are crafted by shaping aluminum sheets into complex, three-dimensional curves, making them ideal for creating visually striking and structurally sound surfaces. Below, we explore their features, benefits, and applications.

1. What Are Aluminum Double-Curved Panels?

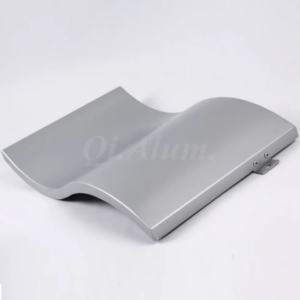

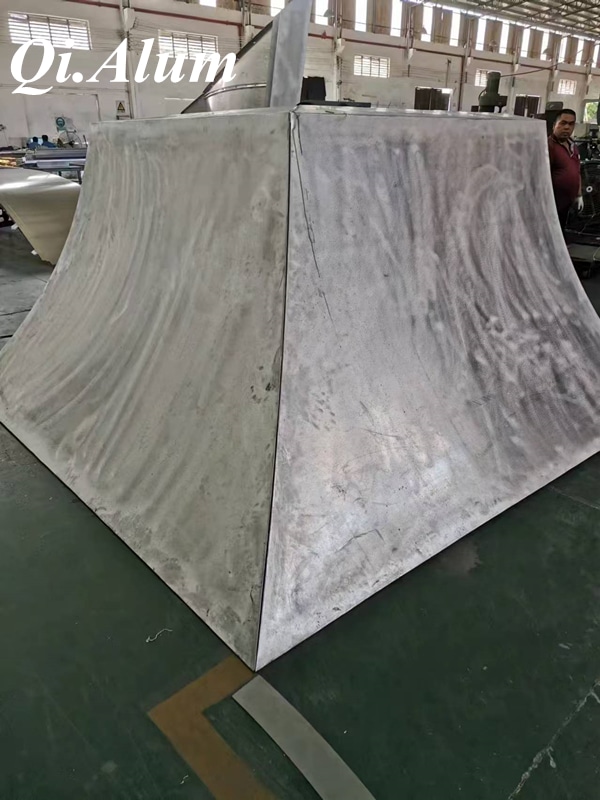

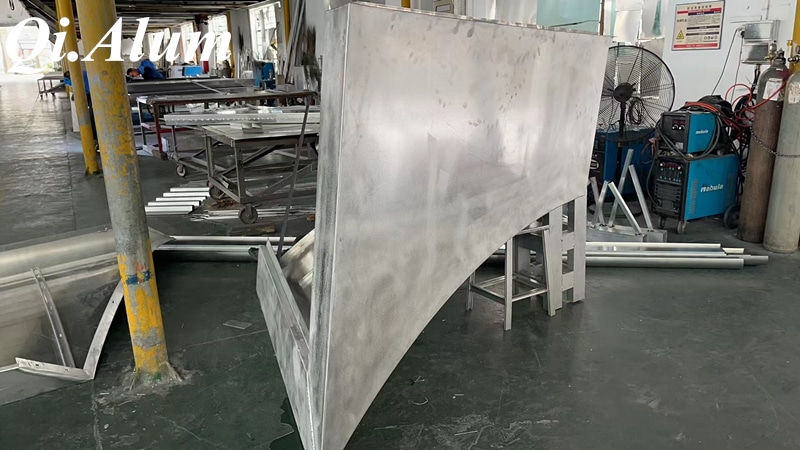

Aluminum double-curved panels are made by bending aluminum sheets along two axes, creating a smooth, flowing surface with compound curves. This process requires advanced manufacturing techniques, such as CNC machining and precision molding, to achieve the desired shapes without compromising the material’s integrity.

2. Key Features

- Lightweight: Aluminum’s low density makes these panels easy to transport and install.

- Durability: Resistant to corrosion, UV rays, and extreme weather conditions.

- Flexibility: Can be molded into various complex shapes, including spheres, waves, and free-form designs.

- Aesthetic Appeal: Smooth, seamless surfaces enhance the visual impact of any structure.

- Sustainability: Aluminum is 100% recyclable, making it an eco-friendly choice.

3. Manufacturing Process

- Design: Using CAD software, architects and engineers create precise 3D models of the desired curves.

- Material Selection: High-quality aluminum sheets are chosen based on thickness and alloy composition.

- Forming: Panels are shaped using techniques like stretch forming, hydroforming, or CNC bending.

- Surface Treatment: Panels are coated with PVDF or powder coatings for enhanced durability and color options.

- Quality Control: Each panel is inspected to ensure it meets design specifications and performance standards.

4. Applications

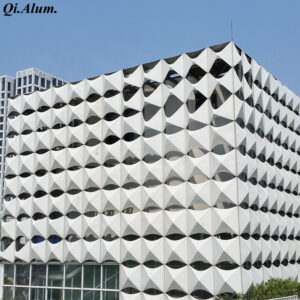

Aluminum double-curved panels are widely used in both exterior and interior applications:

Exterior Applications

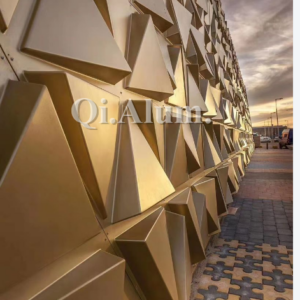

- Building Facades: Create iconic, futuristic designs for skyscrapers, museums, and cultural centers.

- Roofing: Ideal for domes, canopies, and other curved roof structures.

- Sculptural Installations: Used in public art and landmark structures.

Interior Applications

- Ceilings and Walls: Add a dynamic, modern touch to commercial and residential spaces.

- Partitions and Dividers: Create flowing, organic shapes for open-plan layouts.

- Furniture and Decor: Used in custom-designed furniture and decorative elements.

5. Advantages Over Traditional Materials

- Design Freedom: Unlike flat panels, double-curved panels allow for limitless creative possibilities.

- Structural Efficiency: The curved shape enhances strength and reduces the need for additional support.

- Cost-Effectiveness: Despite their complex shapes, these panels are often more economical than alternatives like glass or steel.

- Low Maintenance: Aluminum’s inherent properties make these panels easy to clean and maintain.

6. Case Studies

- The Guggenheim Museum, Bilbao: Known for its iconic curved facade, aluminum panels were used to achieve its fluid, organic design.

- Beijing Daxing International Airport: Double-curved aluminum panels were used to create its futuristic, wave-like roof.

- Burj Al Arab, Dubai: The sail-shaped structure features aluminum panels that withstand harsh desert conditions.

7. Future Trends

- Smart Integration: Incorporating sensors or lighting into panels for interactive designs.

- Sustainable Innovations: Using recycled aluminum and eco-friendly coatings.

- Customization: Advances in manufacturing allow for even more complex and personalized designs.

Conclusion

Aluminum double-curved panels are transforming the architectural landscape, offering a perfect blend of form and function. Their ability to combine aesthetic appeal with structural performance makes them a top choice for modern designers and architects. Whether used in iconic landmarks or everyday spaces, these panels continue to push the boundaries of what is possible in design.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report.If there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation. But shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience. We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!