Description

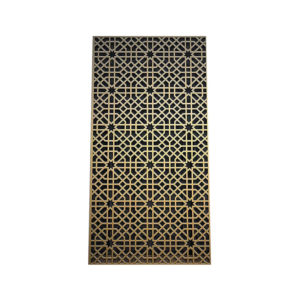

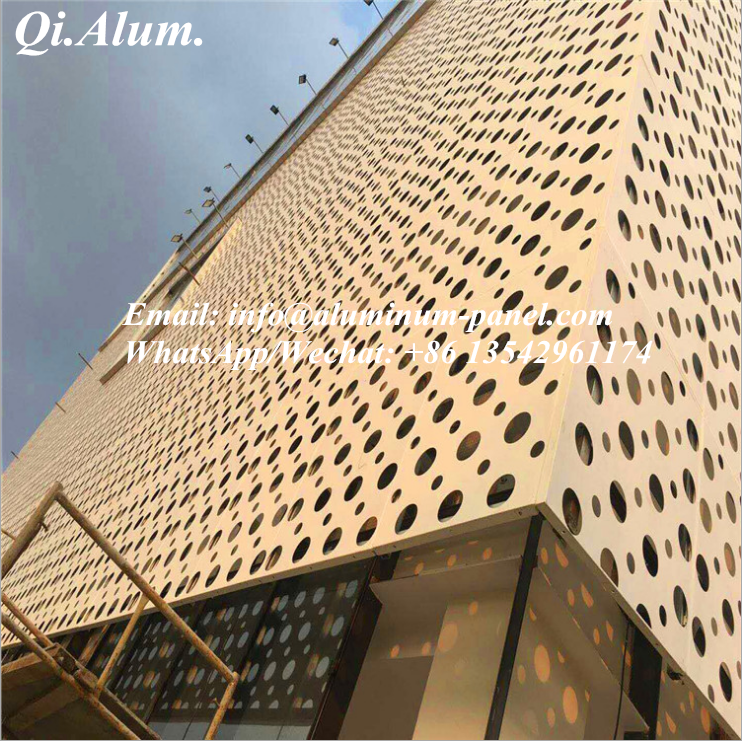

The perforated metal sheet is also known as perforated sheet, perforated plate, punched plate, perforated screen and is sheet metal that typical has been mechanically stamped or punched using specialized tooling in high-speed punching machinery, to create a pattern of holes, slots or decorative shapes.

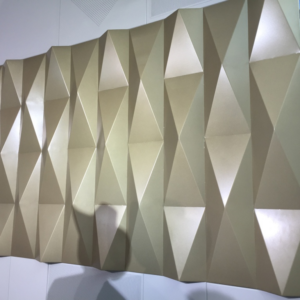

Perforated metal sheet is one of the most versatile and popular metal products on the market today. Perforated sheet can range from light to heavy gauge thickness and any type of material can be perforated, such as perforated carbon steel. Perforated metal is versatile, in the way that it can have either small or large aesthetically appealing openings. This makes perforated sheet metal ideal for many architectural metal and decorative metal uses. Perforated metal is also an economical choice for your project. Our perforated metal filters out solids, diffuses light, air, and sound. It also has a high strength-to-weight ratio.

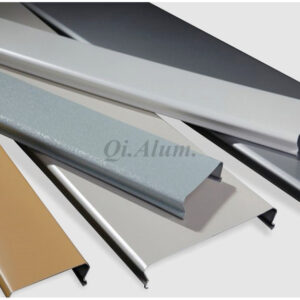

The material can be galvanized sheet, aluminum sheet, stainless steel sheet, brass sheet, etc. The round hole is the most common and economical pattern. In addition, there are square holes, diamond holes, slotted holes, hexagonal holes, and other decorative holes.

| Payment Terms: | L/C, T/T, |

|---|

| Surface Treatment: | Mill Finish, Galvanized, Powder Coated,polyester powder coating |

|---|---|

| Weight: | Middle-weight |

| Usage: | Protection, Aquaculture, Water Conservancy Construction, Civil Building, Railway Construction, Road Construction |

| Application: | Construction Wire Mesh, Protecting Mesh, Decorative Mesh, Filter, Sieving Diversified Pellet, Barbecue Wire Mesh, Cages |

| Material: | Aluminum, Mild Steel, Stainless Steel, etc. |

| Hole Shape: | Round, Diamond, Square, Customize |

Finishing Types

Finishing metal is a demanding task that can make a crucial difference in the appearance and durability of the final product. For the best results, we recommend that you rely on our finishing services. We offer many types:

Anodizing

Anodizing is an electrolytic process used to increase the thickness of the oxidation that naturally forms on the surface of many metals. Typically used with aluminum, anodizing takes advantage of the inherent properties of aluminum oxide to create a hard, corrosion-resistant surface. Anodized aluminum has an attractive metallic sheen, and can be either clear or dyed in various colors.

Features & Benefits of Perforated metal sheet

High strength-to-weight ratio

Economical

Versatile

Functional and aesthetic appeal

Ventilation for air, light, sound, gases

Screening of fluids

Pressure equalization or control

Safety and security

Easy to cut and fabricate

Technique

Using photo etching not laser cut or stamping. By photo etching, the edges of the springs is smooth without any burr. By stamping, the mold cost is high and the thin products will be out of shape easily, but photo etching will keet the thin products flat enough.

Punching Sheet Hole:

Rectangular hole , Square hole , Diamond hole , Hole , Hexagonal hole , Cross hole , Triangle hole , Long hole , Along waist hole , Plum blossom hole , Scale hole , Hole Pattern , Star shaped holes , Irregular holes ,Drum hole etc,

Surface Treatment Process:

Skim →Alkali-Corrosion → Blare-elimination(by acid) →Chromiumizing → Drying → Parts-installation →Spraying Solidifying → Parts- removing → QC& Packing

Fabrication Process:

Sheet Metal Cutting- CNC Cutting(Punching,Laser Cutting-Hollow out)- Bending- Welding-Bracket Fixing-Polishing-Surface Treatment- QC-Package

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence :

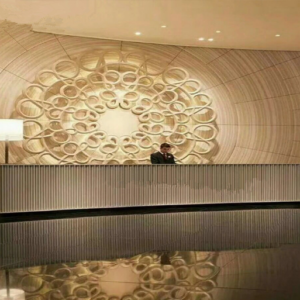

Decorative Living Room, Hotel, Bar, etc.

Indoor and outdoor public space backdrop, Elevator cabin, handrail,living room, background wall, ceiling, Kitchen equipment.

Specially for bar,club,KTV,hotel,bath center,villa,shopping mall

Accordding to CAD Drawing CNC Carving Pattern Aluminum Perforated Panel Outdoor fence:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

Projects list:

Why choose us ?

1. Mission:Focus On Customer’s request and offer the Best Quality and Service!

2. Vision: Improve our own brand’s quality and reputation .

To be one of the best OEM factories in this field ,and set up good sales net in the domestic and overseas market

3.Brief introduction:

We are experienced and energetic team!

– always focus on The customer’s request.

4. We are the manufacturer !

– Industrial design team makes the project design more fashion!

– engineer team makes the project more safe !

– QC team makes the products more qualified!

-factory with hundreds professional workman,make manufacture more efficiently!

FAQ

1. Q:Are you manufacture or simply trading company ?

A: We are the manufacture , welcome you visit our factory.

2.Q: Do you provide free samples ?

A:We do provide free samples under the condition that you assume the express shipping cost

3.Q: How to place order ?

A: Please tell us the service you need, OEM or ODM, and the quantity , then we will make the PI for you.

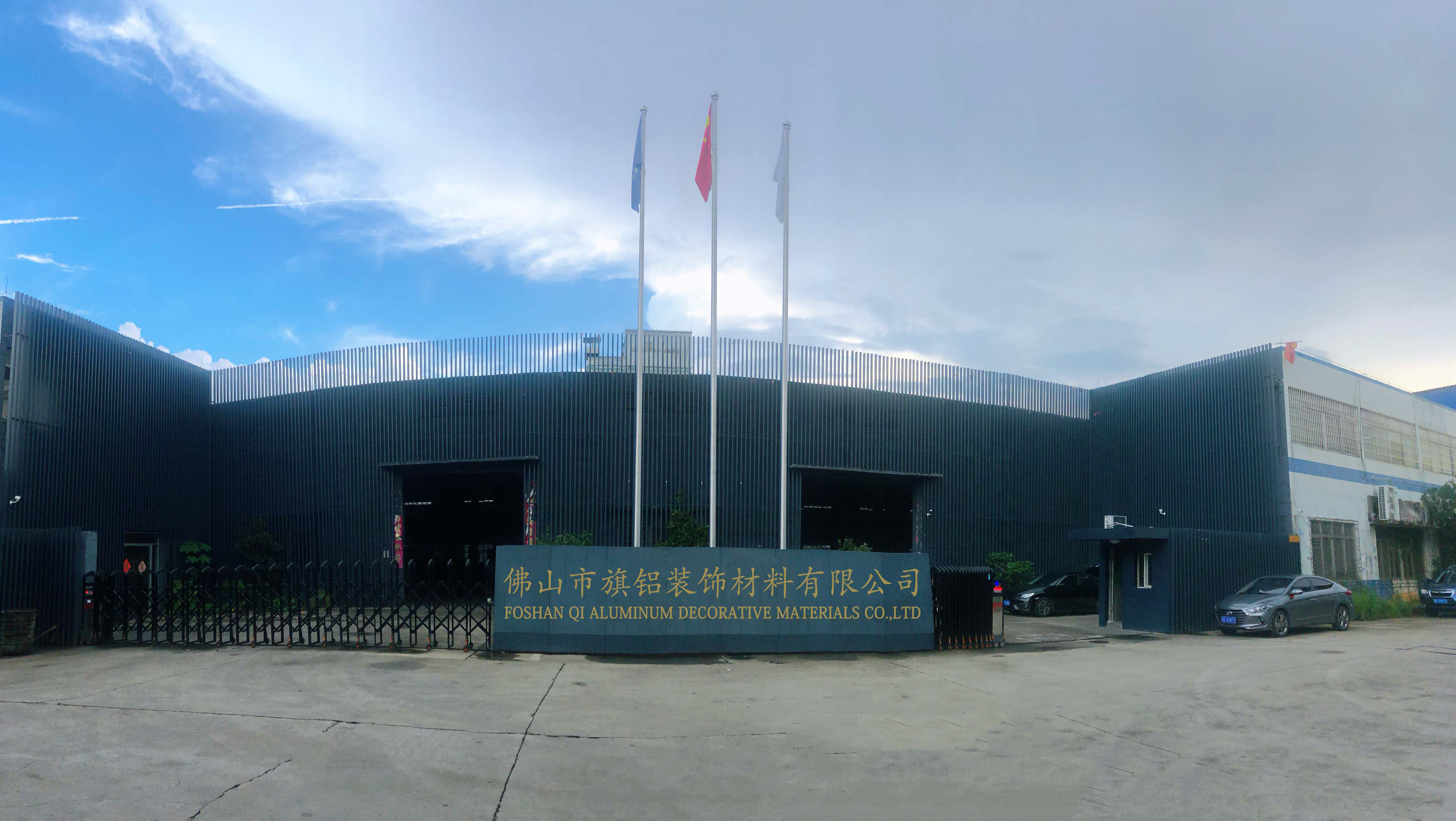

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!